Optical Brightner Conc Grade

Whatsapp Order

Optical Brightner Conc Grade is a highly concentrated fluorescent whitening agent used to enhance the brightness and whiteness of textiles, paper, plastics, and detergents. It works by absorbing ultraviolet light and re-emitting it as visible blue light, thereby compensating for yellowing and dullness in materials. This brightener is valued for its excellent compatibility, high efficiency, and stability in various industrial applications, particularly in detergents and textile processing.

Description

Table of Contents

Toggle

Optical Brightner Conc Grade

Primary Uses

- Detergent Industry

- Incorporated into laundry detergents and soaps to enhance fabric whiteness and brightness.

- Improves perceived cleanliness by making whites appear brighter under UV light.

- Compatible with various detergent formulations including powders and liquids.

- Textile Industry

- Used in fabric finishing processes to brighten white and pastel textiles.

- Applied during bleaching and washing stages to enhance whiteness.

- Provides a lasting brightening effect without compromising fabric quality.

- Paper Industry

- Added to paper coatings and pulp to increase brightness and reduce yellowing.

- Enhances the visual appeal and quality of white and colored paper products.

- Plastic Industry

- Used in plastic products to improve whiteness and opacity.

- Applied in packaging materials to enhance aesthetic appeal.

Secondary Uses

- Cosmetics and Personal Care

- Used in some formulations to impart a brightening effect on skin and hair care products.

- Coatings and Paints

- Incorporated to improve whiteness and brightness of paints and coatings.

- Textile and Leather Finishing

- Employed to enhance the brightness of leather goods and synthetic materials.

- Optical Applications

- Used in optical films and components for brightness and clarity enhancement.

KEY PRODUCT FEATURES

1. Basic Identification Attributes

- Chemical Name (IUPAC): Varies by brightener type (e.g., stilbene derivatives)

- Common/Trade Name: Optical Brightener Conc Grade

- CAS Number: Mixture; varies by formulation

- HS Code: 3204.17.00 (Organic fluorescent brightening agents)

- Synonyms: Fluorescent whitening agent, optical brightener concentrate

2. Physical & Chemical Properties

- Physical State: Concentrated liquid or paste

- Color & Odor: Pale yellow to colorless; mild chemical odor

- Solubility: Soluble in water and common organic solvents

- pH: Typically neutral to slightly alkaline (6.5 – 8.5)

- Stability: Stable under normal storage conditions; resistant to photodegradation

3. Safety & Hazard Attributes

- GHS Classification: Not classified as hazardous under normal use

- Toxicity: Low toxicity; avoid ingestion and prolonged skin contact

- Exposure Limits: Standard chemical handling precautions advised

4. Storage & Handling Attributes

- Storage Conditions: Store in tightly closed containers, away from direct sunlight and heat

- Container Type: Supplied in sealed plastic drums or containers

- Shelf Life: Typically 12 months if stored properly

- Handling Precautions: Use protective gloves and eye protection; avoid inhalation of vapors

5. Regulatory & Compliance Attributes

- Complies with REACH, EPA, and other international chemical regulations

- Approved for use in detergents and textile processing by relevant standards

6. Environmental & Health Impact

- Biodegradability: Moderately biodegradable depending on formulation

- Ecotoxicity: Low to moderate aquatic toxicity; follow disposal guidelines

- Bioaccumulation: Not expected to bioaccumulate significantly

- Carcinogenicity/Mutagenicity: Not classified as carcinogenic or mutagenic

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- PPE Required: Gloves, safety goggles, and protective clothing recommended

- Handling Guidelines: Use in well-ventilated areas; avoid skin and eye contact

- Storage Measures: Keep containers sealed and stored away from incompatible substances

First Aid Measures

- Inhalation: Move to fresh air if irritation occurs; seek medical attention if symptoms persist

- Skin Contact: Wash with soap and water; seek medical advice if irritation develops

- Eye Contact: Rinse thoroughly with water for at least 15 minutes; seek medical attention if irritation persists

- Ingestion: Rinse mouth; do not induce vomiting; seek medical help immediately

Firefighting Measures

- Fire Hazards: Non-flammable under normal conditions

- Extinguishing Media: Use water spray, foam, dry chemical, or CO₂ extinguishers

- Special Precautions: Use standard protective firefighting equipment

- Hazardous Combustion Products: May produce carbon oxides and nitrogen oxides on combustion

Related products

Bentonite Powder

Bentonite powder is a naturally occurring absorbent clay primarily composed of montmorillonite, a type of smectite clay mineral. It exhibits excellent swelling and water absorption properties, making it highly versatile in industrial and commercial applications. Bentonite forms a gel-like substance when mixed with water, which imparts viscosity and plasticity. It is used extensively for its binding, sealing, and adsorptive characteristics. Its fine powder form allows for easy incorporation in various processes including drilling, foundry, cosmetics, pharmaceuticals, and agriculture.

Benzyl Konium Chloride

Benzyl Konium Chloride (BAC) 50% is a quaternary ammonium compound with potent antimicrobial and disinfectant properties. It is a cationic surfactant widely used for its bactericidal, fungicidal, and virucidal effects. This clear to pale yellow liquid concentrate is highly soluble in water and is commonly used in healthcare, sanitation, and industrial hygiene applications. BAC 50% solutions serve as active ingredients in disinfectants, sanitizers, and antiseptics due to their effectiveness against a broad spectrum of microorganisms.

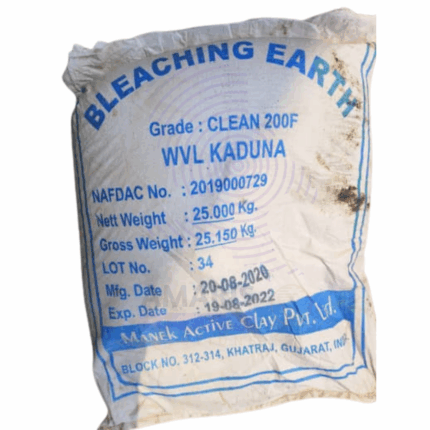

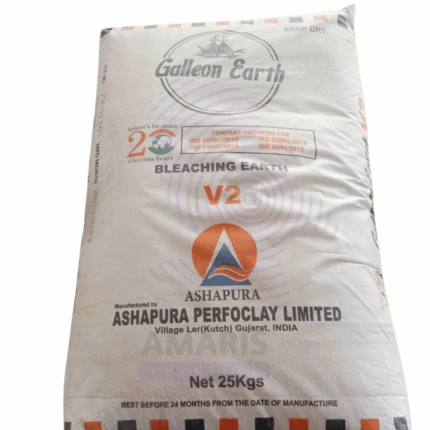

Bleaching Earth

Bleaching Earth is a fine, highly adsorptive clay material derived primarily from bentonite or montmorillonite, and in some cases from attapulgite or sepiolite. It is typically activated using acid treatment to enhance its surface area and pore structure. It is widely used to remove color, contaminants, impurities, and odors from edible oils, fats, waxes, petroleum products, and various industrial fluids. Its high adsorption capacity, non-toxic nature, and effectiveness in filtration make it essential in food processing, chemical industries, cosmetics, and waste treatment applications.

Calcium Hypochlorite

Calcium Hypochlorite Chlorine is a white to slightly yellow crystalline powder or granules known for its strong oxidizing and disinfectant properties. The 65% grade indicates the available chlorine content, making it a powerful bleaching, sanitizing, and oxidizing agent. It is commonly used for water treatment, sanitation, and as a bleaching agent in industrial and household applications. Calcium Hypochlorite dissolves in water to release hypochlorous acid, which effectively kills bacteria, viruses, and fungi.

Nonylphenol Ethoxylate

Nonylphenol Ethoxylate is a non-ionic surfactant belonging to the alkylphenol ethoxylate family, characterized by an average of 9 ethylene oxide units. It is widely used as a detergent, emulsifier, dispersant, and wetting agent in various industrial and commercial applications. NPE9 offers excellent cleaning power, low foaming properties, and good compatibility with other surfactants, making it a versatile ingredient in formulations such as textile processing, paints, coatings, and metal treatment.

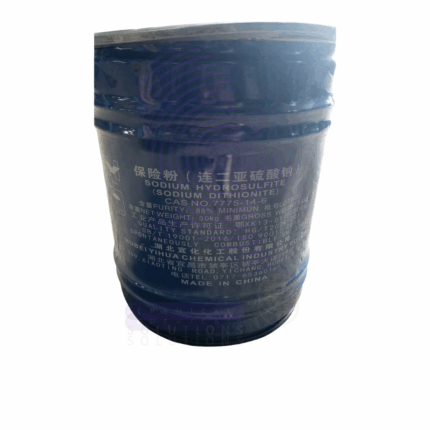

Sodium Hydrosulphite

Sodium Hydrosulphite, also known as sodium dithionite, is a white to yellowish powder with a strong reducing property. It is highly soluble in water and decomposes readily, releasing sulfur dioxide and sulfites. Widely used as a powerful reducing agent and bleaching agent, it finds applications in textile processing, paper and pulp industries, water treatment, and chemical manufacturing. Its ability to break down colored compounds makes it ideal for decolorization and cleaning processes.

Sodium Hypochlorite

Sodium Hypochlorite 10-12% (commonly known as Jik) is a clear to pale greenish-yellow liquid with a strong chlorine odor. It is a widely used disinfectant and bleaching agent, known for its powerful oxidizing properties. This grade is commonly employed in household cleaning, water treatment, and industrial sanitation processes. It is effective against a broad spectrum of microorganisms, making it a popular choice for disinfection and sterilization.

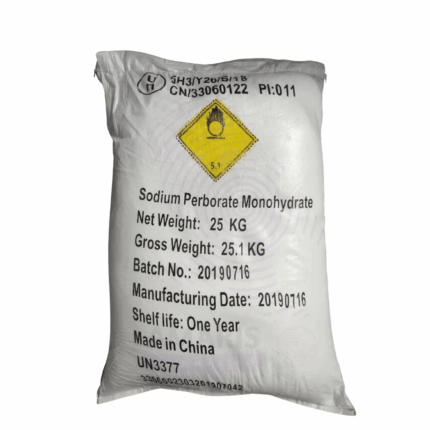

Sodium Perborate

Sodium Perborate is a white crystalline oxidizing compound with the chemical formula NaBO₃·nH₂O (typically tetrahydrate or monohydrate). This versatile chemical serves as a stable, eco-friendly bleaching agent and disinfectant, widely used in detergents, cleaning products, and personal care formulations. Its controlled oxygen release makes it valuable for gentle stain removal and antimicrobial applications while being more environmentally favorable than chlorine-based alternatives.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders