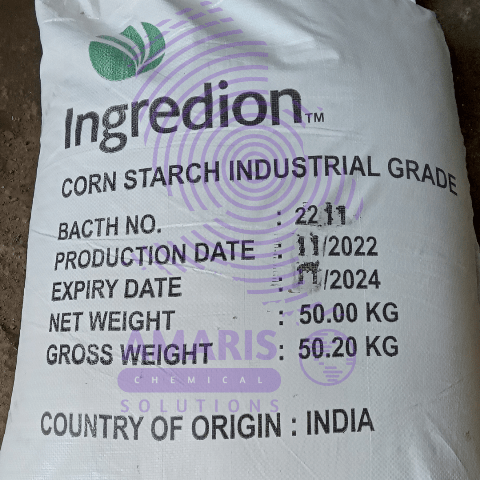

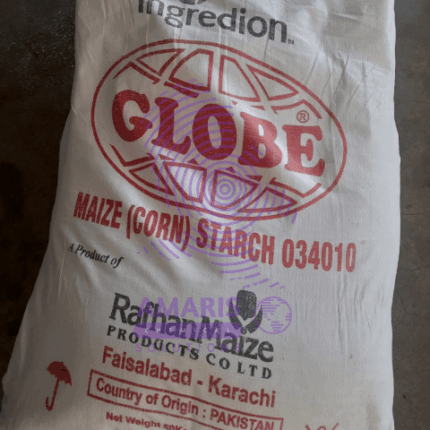

Corn Starch (Industrial grade)

KSh9,500.00 Original price was: KSh9,500.00.KSh9,400.00Current price is: KSh9,400.00.

Corn Starch (Industrial grade) is a fine, powdery substance derived from the endosperm of corn kernels. It is commonly used as a thickening agent in cooking and baking, as well as in other industries such as papermaking, textiles, and adhesives. Corn starch has a neutral flavor and a translucent appearance when mixed with liquid, making it a versatile ingredient in many recipes.

Corn Starch (Industrial grade) Uses

Primary Uses of Industrial Corn Starch

1. Paper & Packaging Industry

- Binder & Coating Agent:

- Improves paper strength, smoothness, and printability.

- Used in corrugated cardboard, paperboard, and recycled paper.

- Surface Sizing: Reduces ink bleed in printing.

2. Textile Manufacturing

- Warp Sizing: Strengthens yarns during weaving to prevent breakage.

- Fabric Finishing: Adds stiffness to fabrics (e.g., shirt collars, curtains).

3. Adhesives & Glues

- Base for Bio-Based Adhesives:

- Used in paper labels, carton sealing, and plywood glue.

- Replaces synthetic resins in some eco-friendly wood adhesives.

4. Biodegradable Plastics & Packaging

- Starch-Based Polymers:

- Used in compostable bags, disposable cutlery, and foam packaging.

- Blended with PLA (polylactic acid) for rigid bioplastics.

5. Foundry & Metal Casting

- Sand Binder: Helps hold molds together in metal casting.

6. Oil & Gas Drilling

- Viscosifier in Drilling Fluids: Controls fluid loss in well drilling.

Secondary Uses of Industrial Corn Starch

1. Construction Materials

- Binder in Gypsum Board & Drywall.

- Dust Suppressanton roads and construction sites.

2. Pharmaceuticals (Non-Edible Applications)

- Tablet Disintegrant(helps pills dissolve).

- Absorbent in Medical Waste Processing.

3. Cosmetics (Non-Food Grade Applications)

- Bulking Agentin talc-free powders.

- Texture Modifierin low-cost creams.

4. Agriculture & Animal Feed

- Pellet Binderfor livestock feed.

- Seed Coatingto improve planting efficiency.

5. Wastewater Treatment

- Flocculant Aid: Helps clump particles for easier filtration.

6. Explosives & Pyrotechnics

- Binder in Fireworks & Safety Matches.

| AVAILABLE PACK SIZE |

50kg( Metal or Plastic Jerrycan/ Bucket, Bag, Box, Polythene bag, Carton bag) |

|---|---|

| COUNTRIES OF ORIGIN |

INDIA |

| AVAILABLE GRADES |

FOOD GRADE ,INDUSTRIAL GRADE |

2 reviews for Corn Starch (Industrial grade)

1. Basic Identification Attributes

- Chemical Name (IUPAC):α-D-Glucopyranosyl-(1→4)-α-D-glucopyranose polymer

- Common/Trade Names:Corn starch, maize starch, food starch

- CAS Number:[9005-25-8]

- HS Code:12.00 (Maize/corn starch)

- Molecular Formula:(C₆H₁₀O₅)ₙ (n = 300-1000)

- Synonyms:Amylum maydis, Zea mays starch

2. Physical & Chemical Properties

- Physical State:Fine white powder

- Color & Odor:Pure white; odorless when dry

- Melting Point:Decomposes at 256-258°C (493-496°F)

- Bulk Density:45-0.55 g/cm³

- Solubility:

- Cold Water:Insoluble (forms suspension)

- Hot Water:Forms translucent paste at >62°C (gelatinization)

- Organic Solvents:Insoluble in ethanol, ether

- Moisture Content:10-13% (as packaged)

- pH Level:5-7.0 (10% slurry)

- Viscosity:

- 5% paste: 300-800 cP (Brookfield, 25°C)

- Gel strength: 200-600 g/cm² (after gelatinization)

- Swelling Power:10-20 g/g (at 95°C)

- Amylose Content:25-28% (typical food grade)

3. Safety & Hazard Attributes

- Hazard Class (GHS):Not classified (non-hazardous)

- NFPA Ratings:

- Health:0

- Flammability:1 (dust explosion risk)

- Reactivity:0

- Exposure Limits:

- OSHA PEL:15 mg/m³ (total dust)

- ACGIH TLV:10 mg/m³ (respirable fraction)

- Dust Explosion Parameters:

- MIE: 20-50 mJ

- MEC: 30-50 g/m³

- Kst: 100-150 bar·m/s (St Class 1)

4. Storage & Handling Attributes

- Storage Conditions:

- Temperature: <25°C

- Humidity: <65% RH

- Shelf Life: 24 months in original packaging

- Packaging Types:

- Multi-wall paper bags (25/50 lb)

- Bulk sacks (1,000-1,500 lb)

- Food-grade PE-lined containers

- Special Handling:

- Ground all equipment (static electricity control)

- Use dust collection systems

- Avoid creating dust clouds

5. Regulatory & Compliance Attributes

- Food Standards:

- FDA:21 CFR 184.1444 (GRAS)

- EU:E1404 (Modified starch)

- CODEX:STAN 152-1985

- Certifications:

- Kosher/Halal available

- Non-GMO verification (when applicable)

- FSSC 22000/ISO 22000

- Allergen Status:Gluten-free when processed appropriately

6. Functional & Nutritional Properties

- Nutritional Value (per 100g):

- Calories: 381 kcal

- Carbohydrates: 91g (of which sugars 0g)

- Protein: 0.3g

- Fat: 0.1g

- Functional Characteristics:

- Thickening begins at 62-72°C

- Maximum viscosity at 92-95°C

- Retrogradation occurs at 4-40°C

- Modification Types (Food Grade):

- Acid-thinned (E1401)

- Oxidized (E1404)

- Acetylated (E1420)

Personal Protective Equipment (PPE):

- NIOSH-approved N95 respirator– Mandatory when handling dry powder to prevent inhalation of fine particles.

- Safety goggles with side shields– Protects against airborne dust irritation.

- Anti-static gloves & clothing– Reduces ignition risk in dusty environments.

Handling & Storage:

- Explosion Prevention:

- Use grounded equipmentto prevent static sparks.

- Implement dust collection systemswith explosion vents.

- Moisture Control:Store in sealed containers at <50% humidity to prevent caking.

- Incompatibilities:Keep away from strong oxidizers (e.g., peroxides, chlorates).

Inhalation (Dust):

- Immediately relocate to fresh air.

- If coughing/wheezing persists, seek medical evaluation for pneumoconiosis risk.

Eye Contact:

- Flush with copious water for 15+ minutes; seek medical help if redness persists.

Skin Contact:

- Wash with soap/water; use emollients if dryness occurs.

Ingestion:

- Rinse mouth; drink water. Not toxic but may cause GI blockage in large quantities.

Hazard Classification:

- Combustible Dust (NFPA 652)– Can form explosive mixtures at ≥30g/m³ concentration.

Extinguishing Agents:

- Primary:Class D dry powder (e.g., sodium chloride-based) for metal fires if starch contacts reactive metals.

- Secondary:Water fog, foam, or CO₂ for contained fires.

Critical Protocols:

- DO NOT use water jets– Creates dust clouds.

- Isolate power sources– Prevent electrostatic ignition.

- Evacuate upwind– Toxic fumes (CO, aldehydes) may release during decomposition.

Minor Spills (<1kg):

- Dampen with water mist, then scoop into plastic bags.

Major Spills:

- Barricade area; use HEPA vacuums for recovery.

- Prevent runoff– Though biodegradable, large quantities can deplete aquatic oxygen.

Disposal:

- Landfill-approved containers; incineration only in permitted facilities.

LABORATORY EQUIPMENT & APPARATUS

LABORATORY EQUIPMENT & APPARATUS

Fertilizers

Fertilizers Plant Growth Regulators

Plant Growth Regulators Soil Conditioners

Soil Conditioners Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Preservatives (baking)

Preservatives (baking)

Surfactants (cleaning)

Surfactants (cleaning) Builders

Builders Bleaching Agents

Bleaching Agents Enzymes

Enzymes Solvents (cleaning)

Solvents (cleaning) Fragrances

Fragrances

Oscar –

Affordable and readily available.

Hansen –

I appreciate its versatility in baking.