Bourdan Gauge

$ 27.11 Original price was: $ 27.11.$ 27.09Current price is: $ 27.09.

Whatsapp Order

The Bourdon Gauge is a mechanical pressure measuring instrument widely used to measure medium to high pressure of gases and liquids in various laboratory and industrial applications. It consists of a curved, hollow metal tube which straightens as pressure increases, causing a pointer to move over a calibrated scale for easy reading. Known for its durability, reliability, and precision, the Bourdon Gauge is essential in pressure monitoring, process control, and safety systems. It operates without electrical power, making it ideal for harsh environments.

Description

Table of Contents

Toggle

Bourdan Gauge

Primary Uses

- Laboratory Applications

- Measures pressure in laboratory gas supply systems and reaction vessels.

- Used in experimental setups requiring precise pressure monitoring.

- Calibrates other pressure measurement devices.

- Monitors vacuum and pressure levels in laboratory vacuum systems.

secondary Uses

- Industrial Applications

- Commonly used in industrial process control to monitor pressure in pipelines, compressors, and pumps.

- Integral in hydraulic and pneumatic systems for pressure regulation and safety.

- Used in HVAC systems for pressure measurement and diagnostics.

- Monitors pressure in boilers, tanks, and gas cylinders.

- Employed in maintenance and safety checks across manufacturing plants.

KEY PRODUCT FEATURES

1.Basic Identification Attributes

- Instrument Type: Mechanical Pressure Gauge

- Measurement Range: Typically 0 to 6000 psi (varies by model)

- Material: Stainless steel or brass housing with bourdon tube

- Display: Analog dial with pointer

2.Physical & Chemical Properties

- Operating Temperature Range: -40°C to 120°C (depending on model)

- Pressure Medium: Gases and liquids compatible with gauge materials

- Durability: Resistant to vibration and mechanical shock

3.Safety & Hazard Attributes

- Mechanical Risk: Risk of sudden rupture under extreme pressure; use within specified limits

- Toxicity: Non-toxic materials

- Allergens: None identified

4.Storage & Handling Attributes

- Store in a dry, dust-free environment

- Protect from physical impacts during handling and storage

5.Regulatory & Compliance Attributes

- Compliant with international standards such as ASME B40.1 and EN 837

- Manufactured under quality management systems (ISO 9001)

6.Environmental & Health Impact

- Materials recyclable according to local regulations

- No significant environmental hazards during normal use

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- Avoid exceeding pressure limits to prevent tube failure

- Inspect regularly for damage or corrosion

First Aid Measures

- Mechanical injury: Clean and treat wounds caused by broken gauge components immediately

Firefighting Measures

- Non-flammable device

- No special firefighting measures required

Related products

Balance Mechanical Ohaus Centre

Balance Mechanical Ohaus Centre is a high-precision mechanical balance designed for laboratory and industrial use. Featuring a central zero adjustment, this balance enables accurate measurement of small to medium-weight samples with fine calibration control. Constructed with durable, corrosion-resistant materials, it delivers reliable and consistent weighing results without requiring electrical power. Its simple mechanical design ensures easy operation and maintenance, making it suitable for research laboratories, quality control departments, and industrial environments where precise manual weighing is essential.

Bunsen Burner Lighter

The Bunsen Burner Lighter is a handheld ignition device designed specifically to ignite Bunsen burners and other laboratory gas burners safely and efficiently. It typically features a long, insulated handle with a spark-producing mechanism that allows users to light gas flames without risk of burns. Constructed from durable materials resistant to heat and corrosion, the lighter provides reliable ignition in laboratory environments, ensuring safe and convenient operation during experiments and heating tasks.

Burette Clamp

The Burette Clamp is a laboratory apparatus designed to securely hold burettes in place during titration and other volumetric procedures. Made from durable materials such as metal with rubber or plastic-coated grips, it ensures stability and prevents slippage or breakage. The clamp typically attaches to a retort stand or support rod, allowing hands-free operation and precise liquid dispensing.

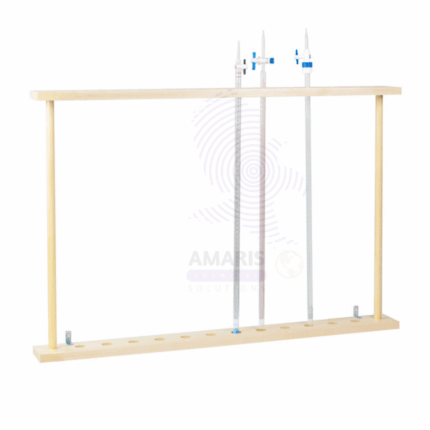

Burette stand for drying

The Burette Stand for Drying is a laboratory accessory designed to securely hold burettes in an upright position during drying and storage. Made from durable, corrosion-resistant materials such as stainless steel or coated metal, the stand ensures stability and prevents damage or contamination of delicate glassware. Its design facilitates proper air circulation, promoting efficient drying and maintaining the cleanliness of burettes between uses.

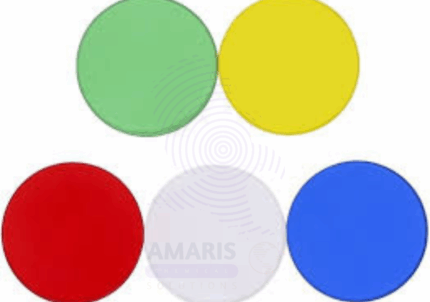

Color Filters

Color Filters are optical components designed to selectively transmit light of specific wavelengths while absorbing or reflecting others. These filters are used in various laboratory and industrial applications to isolate particular colors for scientific experiments, photography, microscopy, and optical analysis. Manufactured from high-quality glass or plastic materials, color filters ensure consistent performance with minimal distortion and high durability.

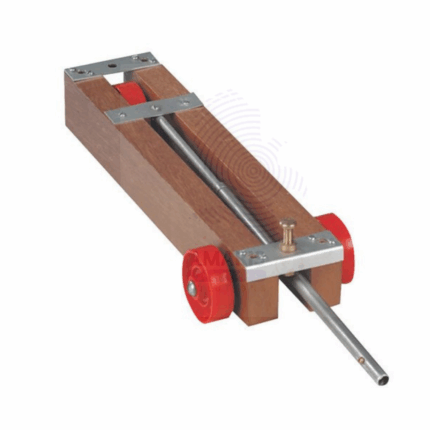

Dynamic Trolley

Dynamic Trolley is a durable equipment designed for safe and efficient transportation of materials, instruments, or chemicals within laboratory and industrial settings. Built with sturdy frames and smooth wheels, it aids in moving heavy or bulky items, improving workflow and minimizing physical strain. Essential for organized handling and transport in labs, manufacturing plants, and warehouses.

Electric Incubator

Electric Incubator is a precision-controlled laboratory device designed to provide a stable and uniform environment for the incubation of biological samples, cultures, and experimental materials. It operates by maintaining a constant temperature and humidity level through electric heating elements, fans for air circulation, and advanced thermostatic controls. Commonly constructed with insulated walls, a transparent viewing window, and adjustable shelves, electric incubators are essential in microbiology, biotechnology, pharmaceutical, and agricultural laboratories. They facilitate optimal growth conditions for microorganisms, cell cultures, and eggs, enabling research, diagnostic, and production processes. The device’s reliability, accuracy, and ease of use make it indispensable for maintaining controlled incubation parameters in various scientific and industrial applications.

Model steam engine

A Model Steam Engine is a scaled-down, functional representation of a steam-powered engine used primarily for educational, demonstration, and hobbyist purposes. This apparatus demonstrates the basic principles of thermodynamics, mechanical energy conversion, and steam power operation in a compact, visible form. Typically constructed from metal components such as brass and steel, the model includes key parts like a boiler, piston, cylinder, crankshaft, and flywheel. Steam generated in the boiler expands and pushes the piston, converting thermal energy into mechanical motion that turns the flywheel. Model steam engines are invaluable tools for physics and engineering education, illustrating steam mechanics, energy transfer, and engine operation clearly and tangibly. They are also popular among collectors and model enthusiasts.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders