Deionized water

$1,000.00 Original price was: $1,000.00.$850.00Current price is: $850.00.

Deionized water, also known as demineralized water, is water that has had its mineral ions (such as sodium, calcium, iron, and copper) and dissolved solids removed through a process called ion exchange.

Distilled water, on the other hand, is water that has been purified by boiling it into steam and then condensing the steam back into water. This process removes impurities such as minerals, bacteria, and other contaminants.

Both deionized and distilled water are highly purified forms of water, but the processes used to purify them are different. Deionized water is typically used in laboratory settings or in industrial processes, while distilled water is commonly used in medical applications, humidifiers, and in some consumer products

Primary Uses of Deionized Water

1. Laboratory & Scientific Research

-

Solvent for reagents (prevents mineral interference).

-

Calibration of lab equipment (pH meters, spectrophotometers).

-

Preparation of buffer solutions.

2. Pharmaceuticals & Medical Applications

-

Manufacturing IV fluids, injections, and dialysis water.

-

Cleaning medical devices (prevents mineral deposits).

3. Electronics & Semiconductor Industry

-

Wafer rinsing in chip manufacturing (avoids mineral contamination).

-

PCB (circuit board) cleaning.

-

Coolant for high-precision machinery.

4. Automotive & Batteries

-

Lead-acid battery filling (extends battery life).

-

Radiator coolant mixing (prevents scaling).

5. Industrial Processes

-

Boiler feed water (reduces scaling in steam systems).

-

Chemical manufacturing (ensures reaction purity).

6. Cosmetics & Personal Care

-

Base for lotions, toners, and sensitive skincare (no mineral irritation).

Secondary Uses of Deionized Water

1. Food & Beverage Industry

-

Ingredient in soft drinks, beer brewing (avoids flavor alteration).

-

Cleaning food processing equipment (no water spots).

2. Aquariums & Aquatic Life

-

Mixing with salts for marine tanks (no unwanted minerals).

3. Photography & Printing

-

Film development & inkjet printers (prevents clogging).

4. HVAC Systems

-

Humidifier filling (reduces white dust).

5. Glass & Window Cleaning

-

Streak-free washing (no mineral residues).

6. Fire Extinguishers

-

Used in water mist systems (non-conductive, safe for electrical fires).

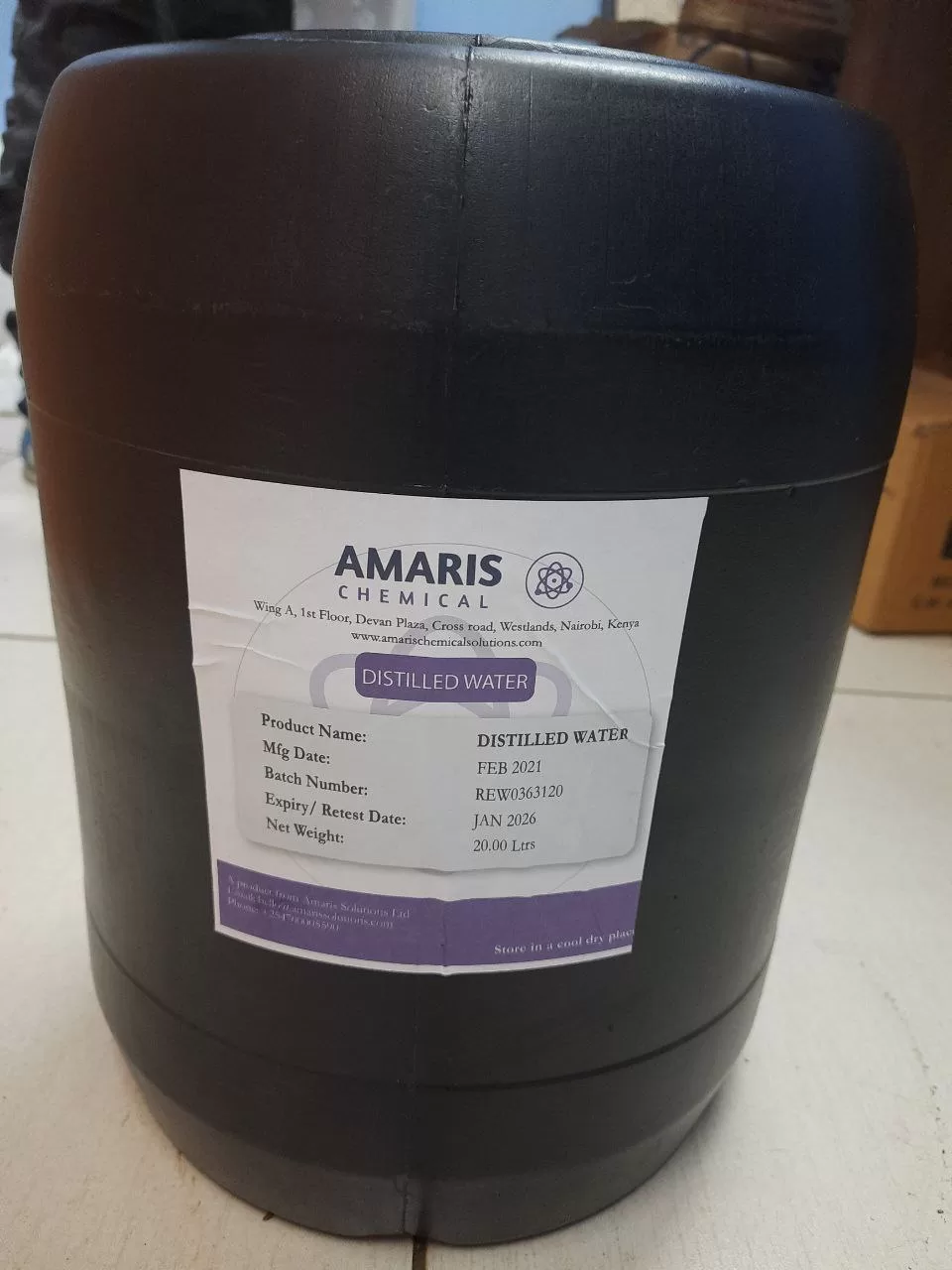

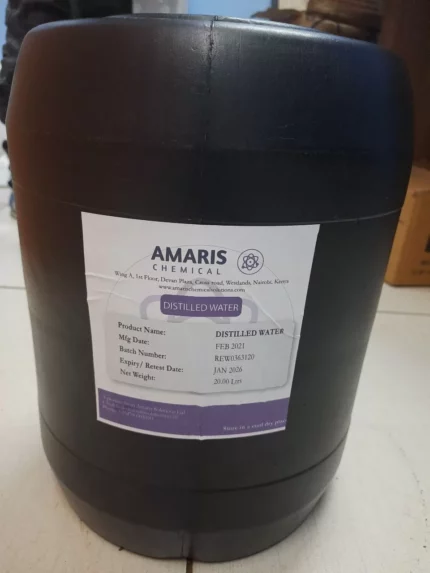

| APPEARANCE |

Watery/Thin – Low viscosity e.g., ethanol |

|---|---|

| COUNTRIES OF ORIGIN |

KENYA |

| AVAILABLE PACK SIZE |

20 Litres |

1. Basic Identification Attributes

- Chemical Name:Oxidane (IUPAC), Water

- Common/Trade Names:Deionized water, Demineralized water, DI water, Ultra-pure water

- CAS Number:[7732-18-5]

- HS Code:00.00 (Distilled/conductivity water)

- Molecular Formula:H₂O

- Synonyms:Purified water, High-purity water, Type II water (per ASTM)

2. Physical & Chemical Properties

- Physical State:Liquid

- Color & Odor:Colorless, odorless

- Boiling Point:100°C (212°F) at 1 atm

- Melting Point:0°C (32°F)

- Density:998 g/cm³ at 20°C

- Solubility:Universal solvent (dissolves many ionic compounds)

- pH Level:5-7.5 (can become acidic when exposed to air due to CO₂ absorption)

- Conductivity:<1 µS/cm (typically 0.055-0.1 µS/cm)

- Resistivity:>1 MΩ·cm (typically 18.2 MΩ·cm at 25°C)

- Vapor Pressure:34 kPa at 20°C

- Surface Tension:8 mN/m at 20°C

- Specific Heat Capacity:18 J/g·K

3. Safety & Hazard Attributes

- Hazard Class:Non-hazardous (OSHA/GHS)

- NFPA Ratings:Health: 0, Flammability: 0, Reactivity: 0

- Exposure Limits:None established

- Reactivity:

- Reacts violently with alkali metals

- Incompatible with strong oxidizing agents

- Can promote corrosion in pure form

4. Storage & Handling Attributes

- Storage Conditions:

- Polyethylene or polypropylene containers

- Sealed to prevent CO₂ absorption

- Ambient temperature preferred

- Shelf Life:

- 24 hours for ultra-pure applications

- Up to 1 month in sealed containers

- Special Handling:

- Use in clean environments to maintain purity

- Avoid contact with air to prevent contamination

5. Regulatory & Compliance Attributes

- Regulatory Status:

- USP Purified Water (USP <1231>)

- ASTM Type II (D1193)

- EP Purified Water (European Pharmacopoeia)

- Purity Standards:

- Conductivity: <1.3 µS/cm at 25°C (USP)

- TOC: <500 ppb (USP)

- Endotoxin: <0.25 EU/ml (for USP Water for Injection)

6. Environmental & Health Impact

- Ecotoxicity:None (natural substance)

- Persistence:N/A (part of natural water cycle)

- Biodegradability:N/A (not applicable)

- Health Effects:

- Excessive consumption can cause hyponatremia

- No toxicity in normal use

General Handling:

Electrical Safety:

- High-purity DI water is more conductive than distilled water—keep away from live circuits.

- Avoid spills near electrical equipment.

Material Compatibility:

- Can leach ionsfrom metals, glass, or plastics over time.

- Avoid long-term storage in reactive containers (e.g., some plastics, untreated steel).

Personal Protective Equipment (PPE):

- Gloves (optional):Nitrile gloves if handling large volumes (prevents contamination).

- Safety goggles:Only needed if splashing risk exists (e.g., pressurized systems).

Storage:

- Use chemically inert containers(HDPE, PTFE, or glass).

- Seal tightly to prevent CO₂ absorption(forms carbonic acid, lowering pH).

Inhalation:

- Not applicable (non-volatile).

Skin Contact:

- No action needed (non-irritating).

- Dry skin if exposed repeatedly (may cause mild dryness).

Eye Contact:

- Rinse with clean water for 5–10 minutes(DI water lacks buffering ions).

- Seek medical help only if irritation persists (unlikely).

Ingestion:

- Harmless in small amounts.

- Large quantitiesmay cause electrolyte imbalance—seek medical advice if consumed excessively.

- Non-flammable.

- Not a fire hazard, but do NOT use to extinguish:

- Electrical fires (unless de-energized).

- Water-reactive chemicals (e.g., alkali metals, strong acids).

Special Cases:

- If DI water is contaminated with organics/flammables, treat as the contaminant’s hazard.

Cleanup:

- Wipe up with absorbent materials (e.g., lint-free cloths).

- For large spills, use a wet/dry vacuum.

Environmental Notes:

- No ecological toxicity, but large spills may:

- Dilute local water chemistry.

- Damage equipment if leaked into sensitive areas (e.g., labs, electronics).

Emollients

Emollients Humectants

Humectants UV Filters

UV Filters Surfactants (cosmetic)

Surfactants (cosmetic) Preservatives (cosmetic)

Preservatives (cosmetic) Fragrances and Essential Oils

Fragrances and Essential Oils Antioxidants (cosmetics)

Antioxidants (cosmetics)

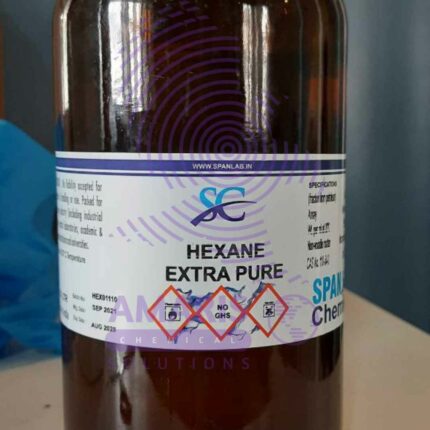

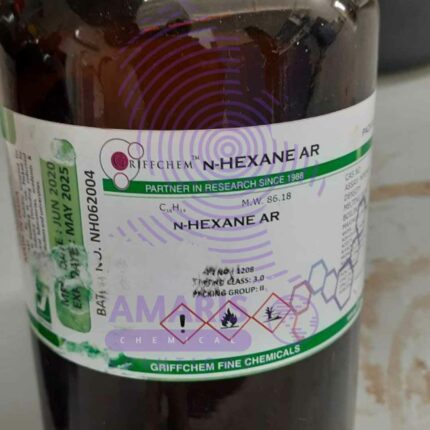

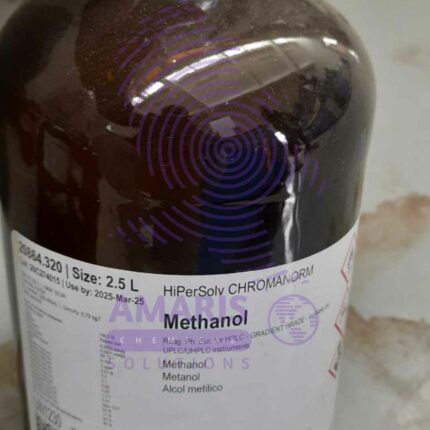

Solvents (lab)

Solvents (lab) Chromatography Chemicals

Chromatography Chemicals Microbiology and Cell Culture Reagents

Microbiology and Cell Culture Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Spectroscopy Reagents

Spectroscopy Reagents Molecular Biology Reagents

Molecular Biology Reagents

Precious Metal Extraction Agents

Precious Metal Extraction Agents

Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers

Stabilizers Monomers

Monomers Fillers and Reinforcements

Fillers and Reinforcements Antioxidants (plastics)

Antioxidants (plastics) Colorants (plastic pigments,Dyes)

Colorants (plastic pigments,Dyes)

Fertilizers

Fertilizers Plant Growth Regulators

Plant Growth Regulators Soil Conditioners

Soil Conditioners Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants

Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Preservatives (baking)

Preservatives (baking)

Surfactants (cleaning)

Surfactants (cleaning) Builders

Builders Bleaching Agents

Bleaching Agents Enzymes

Enzymes Solvents (cleaning)

Solvents (cleaning) Fragrances

Fragrances Disinfectant

Disinfectant Metal cleaning

Metal cleaning

Binders/Resins

Binders/Resins Pigments

Pigments Solvents (paint)

Solvents (paint) Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Specialty Coatings

Specialty Coatings Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Sealants and Adhesives

Sealants and Adhesives

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Preservatives (food)

Preservatives (food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Emulsifiers

Emulsifiers Antioxidants (food)

Antioxidants (food) Colorants (food)

Colorants (food) Nutrient Supplements

Nutrient Supplements Nutraceutical Ingredients

Nutraceutical Ingredients

Fresh Herbs

Fresh Herbs Whole Spices

Whole Spices Ground Spices

Ground Spices Spice Blends

Spice Blends

Surfactants(oil)

Surfactants(oil)

Antibiotics

Antibiotics Active Pharmaceutical Ingredients

Active Pharmaceutical Ingredients Excipients

Excipients Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients

Nutraceutical Ingredients Solvents (pharmaceutical)

Solvents (pharmaceutical)

Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Vulcanizing Agents

Vulcanizing Agents Accelerators & Retarders

Accelerators & Retarders Antidegradants

Antidegradants Reinforcing Agents

Reinforcing Agents Plasticizers & Softeners

Plasticizers & Softeners Fillers & Extenders

Fillers & Extenders Blowing Agents

Blowing Agents Adhesion Promoters

Adhesion Promoters