Model Diesel Engine

$ 92.97 Original price was: $ 92.97.$ 92.88Current price is: $ 92.88.

Trisodium Citrate

$ 2.55 Original price was: $ 2.55.$ 2.45Current price is: $ 2.45.

Eyedrop Dropper Bottle

$ 8.12 Original price was: $ 8.12.$ 8.07Current price is: $ 8.07.

Whatsapp Order

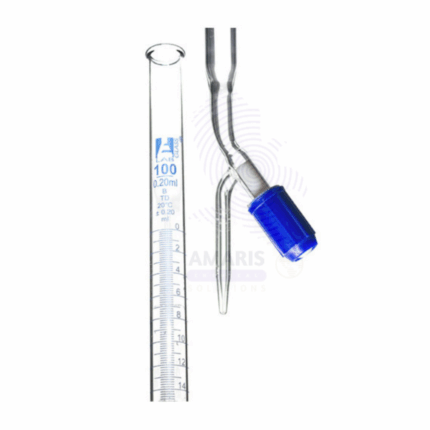

Eyedrop Dropper Bottle is a small, precision container designed for dispensing liquids in controlled, small volumes, commonly used for medicinal eye drops, laboratory reagents, or cosmetic liquids. These bottles are usually made from chemically resistant plastic or glass and come equipped with a dropper cap or teat for accurate drop-by-drop delivery. The secure closure prevents contamination and leakage, making them ideal for medical, pharmaceutical, and laboratory applications. Their design ensures hygiene, ease of handling, and precise dosage control.

Description

Table of Contents

Toggle

Eyedrop Dropper Bottle

Primary Uses

- Medical and Pharmaceutical Applications

- Dispensing eye drops and other medicinal liquid formulations with precise control.

- Administering topical medications in ophthalmology and dermatology.

- Sample preparation in laboratory environments requiring accurate liquid handling.

- Application of reagents dropwise in chemical or biological experiments.

- Cosmetic Uses

- Packaging and dispensing cosmetic serums and essential oils in small quantities.

- Controlled application of skincare products requiring hygienic delivery.

Secondary Uses

- Research and Educational Uses

- Use in laboratories for titration and reagent addition in small volumes.

- Teaching aid for demonstrating precise liquid measurement techniques.

- Industrial Applications

- Dispensing lubricants or chemicals in electronic component manufacturing.

- Applying cleaning solutions in delicate equipment maintenance.

KEY PRODUCT FEATURES

1.Basic Identification Attributes

- Material: Chemically resistant plastic or glass

- Closure Types: Dropper cap or teat for controlled dispensing

- Sizes: Available in various small volumes, typically from 5ml to 50ml

2.Physical & Chemical Properties

- Chemical Resistance: Suitable for a wide range of medicinal and chemical liquids

- Transparency: Clear or translucent for easy content monitoring

- Durability: Leak-proof design to prevent spills and contamination

3.Safety & Hazard Attributes

- Small parts pose choking hazards; keep away from children

- Proper hygiene required to avoid contamination of liquids

4.Storage & Handling Attributes

- Store in cool, dry, and hygienic environments

- Use with care to maintain dropper sterility and liquid integrity

- Inspect for damage or contamination before use

5.Regulatory & Compliance Attributes

- Manufactured to meet pharmaceutical and medical packaging standards

- Suitable for use in GMP compliant pharmaceutical and laboratory settings

6.Environmental & Health Impact

- Some components are recyclable; proper disposal recommended

- Designed to minimize contamination and waste through controlled dosing

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- Use aseptic techniques to avoid contamination

- Avoid contact with eyes and skin when handling hazardous liquids

First Aid Measures

- In case of accidental contact with harmful substances, rinse immediately and seek medical advice

Firefighting Measures

- Non-flammable bottle material

- Use extinguishing methods appropriate for surrounding materials

Related products

Amber laboratory reagent bottles

Amber Laboratory Reagent Bottles are high-quality glass containers designed specifically for storing light-sensitive reagents and chemicals in laboratory settings. The amber color provides effective protection against ultraviolet (UV) and visible light that can degrade sensitive compounds. These bottles feature durable construction with chemical-resistant glass and secure closures to maintain sample integrity and prevent contamination. Commonly used in chemical, pharmaceutical, and research laboratories, Amber Laboratory Reagent Bottles ensure safe, reliable storage and handling of a wide range of reagents.

Aspirator Bottle Glass

Aspirator Bottle Glass is a durable, high-quality glass container designed specifically for use in laboratory suction and aspiration systems. These bottles are engineered to safely collect and contain liquids and aerosols during filtration, vacuum, or aspiration procedures. Made from chemically resistant glass, Aspirator Bottles offer excellent clarity and durability while withstanding the rigors of laboratory use. They typically feature secure screw caps or stopper closures that ensure leak-proof performance and easy handling. Widely used in medical, research, and industrial laboratories, Aspirator Bottle Glass is essential for safe fluid management in various applications.

Burette rotaflow

Product Description

The Burette RotaFlow is a precision laboratory instrument designed for controlled and accurate dispensing of liquids during titration. Featuring a rotatable valve mechanism, it allows smooth flow adjustment and easy operation. Constructed from high-quality borosilicate glass with chemically resistant components, this burette ensures durability and precision, suitable for a wide range of laboratory applications involving acids, bases, and other reagents.

Centrifuge tubes

Centrifuge Tubes are specially designed containers used for holding samples during centrifugation. Made from high-quality, chemically resistant plastic or glass, these tubes withstand the high centrifugal forces generated during lab procedures. Available in various volumes and designs, including conical bottoms for easy sediment collection, centrifuge tubes are essential for separating components in biological, chemical, and industrial samples. They are compatible with a wide range of centrifuge models and ensure sample integrity and safety during processing.

Clear laboratory reagent bottles

Product Description

Clear Laboratory Reagent Bottles are high-quality, transparent containers designed specifically for storing, transporting, and dispensing chemical reagents and solutions in laboratory settings. Made from durable borosilicate glass or high-grade plastic materials, these bottles offer excellent chemical resistance, clarity for easy identification of contents, and airtight sealing to maintain reagent integrity. They are essential in analytical, biochemical, and industrial laboratories for safe and organized chemical storage.

Combustion Boat

Product Description

The Combustion Boat is a small, heat-resistant container typically made of porcelain or quartz, designed to hold samples during combustion analysis. It is used primarily in laboratories to contain solid or powdered samples that are subjected to high temperatures for elemental analysis, especially in organic and inorganic chemistry. The boat withstands extreme temperatures without reacting with the sample, ensuring accurate and uncontaminated results.

Cork to fit boiling tube cork stopper

Cork to Fit Boiling Tube Cork Stopper is a precision-manufactured stopper made from natural or synthetic cork, designed specifically to fit standard boiling tubes. It ensures a snug, secure closure that prevents leaks, contamination, or evaporation during laboratory procedures. These stoppers are essential in both routine and specialized lab applications where temporary sealing of test vessels is required. With good compressibility, mild chemical resistance, and reliable sealing properties, the stopper is a staple in laboratory glassware accessories.

Density Bottle

The Density Bottle is a precision glassware device used for determining the density of liquids by measuring a known volume and mass. Typically made from high-quality borosilicate glass, the bottle features a tight-fitting stopper with a capillary hole to allow excess liquid to escape, ensuring volume accuracy. It is commonly used in laboratory settings for experiments in physical chemistry, materials science, and industrial quality control processes. The device provides a reliable method for comparing the density of various substances with high repeatability.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders