Masterbatch White ( PEW60)

Whatsapp Order

Masterbatch White PEW60 is a high-quality white pigment masterbatch designed for incorporation into polyethylene (PE) and other polyolefin resins. Containing 60% titanium dioxide (TiO₂) pigment, it provides excellent whiteness, opacity, and brightness to plastic products. PEW60 improves aesthetic appeal and surface finish while maintaining the mechanical properties of the base resin. It is widely used in film extrusion, injection molding, blow molding, and other plastic manufacturing processes to produce a consistent, bright white color.

Description

Table of Contents

Toggle

Masterbatch White ( PEW60)

Primary Uses

- Colorant in Polyethylene Processing

- Used in PE film extrusion to produce white agricultural films, packaging films, and shrink films.

- Applied in injection molding of household items, containers, and consumer goods requiring white coloration.

- Enhances opacity and brightness in blow molded products such as bottles and drums.

- UV Protection and Surface Finish

- Provides partial UV shielding to plastics, improving weather resistance.

- Improves surface gloss and reduces translucency in finished parts.

Secondary Uses

- Compounding and Masterbatch Production

- Used as a base for further color masterbatch blends.

- Employed in specialty polymer blends requiring enhanced whiteness and opacity.

KEY PRODUCT FEATURES

1. Basic Identification Attributes

- Chemical Name (IUPAC): Titanium dioxide pigment in polyethylene carrier

- Common/Trade Name: Masterbatch-White 60% (PEW60)

- CAS Number: 13463-67-7 (Titanium dioxide)

- HS Code: 3206.11.00

- Synonyms: White pigment masterbatch; TiO₂ masterbatch; polyethylene white concentrate

2. Physical & Chemical Properties

- Physical State: Solid pellets or granules

- Color & Odor: White; odorless

- Density: Approximately 1.1 – 1.3 g/cm³ (depending on carrier resin)

- Solubility: Insoluble in water and organic solvents

3. Safety & Hazard Attributes

- GHS Classification: Not classified as hazardous under normal handling

- Toxicity: Low toxicity; inert polymer carrier with pigment additives

- Exposure Limits: Standard dust precautions advised during handling

4. Storage & Handling Attributes

- Storage Conditions: Store in a cool, dry area away from direct sunlight and moisture

- Container Type: Supplied in sealed bags or boxes to maintain quality

- Shelf Life: 12 to 24 months if stored properly

- Handling Precautions: Avoid dust inhalation; use PPE if necessary

5. Regulatory & Compliance Attributes

- Complies with plastics additive regulations and safety standards

- Free from heavy metals and harmful contaminants as per industry norms

6. Environmental & Health Impact

- Biodegradability: Not biodegradable; inert and stable

- Ecotoxicity: Low environmental impact when disposed of properly

- Bioaccumulation: Not applicable

- Carcinogenicity/Mutagenicity: Titanium dioxide classified as a possible carcinogen by inhalation in powder form; avoid dust exposure

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- PPE Required: Dust mask or respirator, gloves, and eye protection recommended during handling

- Handling Guidelines: Use in well-ventilated areas to minimize dust exposure

- Storage Measures: Keep containers sealed and dry

First Aid Measures

- Inhalation: Move to fresh air; seek medical attention if respiratory symptoms develop

- Skin Contact: Wash with soap and water if irritation occurs

- Eye Contact: Rinse eyes thoroughly with water; consult a physician if irritation persists

- Ingestion: Rinse mouth and seek medical advice if large amounts ingested

Firefighting Measures

- Fire Hazards: Non-flammable; polymer base may burn producing toxic fumes

- Extinguishing Media: Use water spray, foam, or dry chemical extinguishers

- Special Precautions: Use self-contained breathing apparatus if involved in fire

- Hazardous Combustion Products: Carbon monoxide, carbon dioxide, and toxic fumes

Related products

Black Five 5 Pigment

Black Five 5 Pigment is a high-quality synthetic pigment known for its intense, deep black coloration and excellent opacity. It is widely used in various industrial applications due to its outstanding color strength, stability, and resistance to heat, light, and chemicals. This pigment offers superior dispersibility in multiple media, making it ideal for use in paints, coatings, plastics, inks, and rubber products.

Black Five (5) Pigment delivers rich black tones with excellent durability, providing long-lasting color performance in demanding environments. Its non-toxic nature and compatibility with a wide range of formulations make it a preferred choice for both industrial and artistic applications.

Cetex Green Dye sdn Oil Soluble

Cetex Green Dye sdn oil soluble is a synthetic oil-soluble dye known for its vibrant green coloration and excellent solubility in oils, fats, and hydrocarbon solvents. It is widely used in industries requiring stable and intense green color in oil-based formulations. The dye exhibits good resistance to heat, light, and chemical exposure, making it suitable for applications in cosmetics, plastics, and inks. Cetex Green Dye SDN offers consistent color strength and dispersion in various oil mediums.

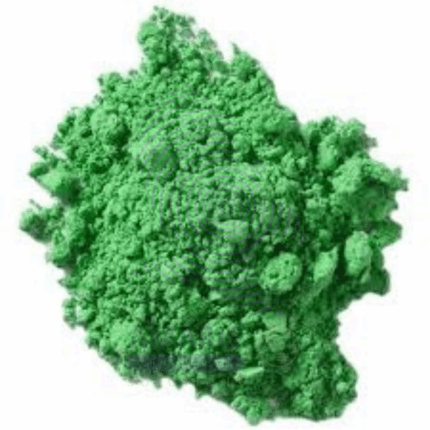

Green Pigment

Green Pigment is a concentrated dispersion of green pigment particles in a suitable carrier, designed for use in a variety of industrial and commercial applications. Known for its vivid green color and excellent stability, this pigment offers good resistance to heat, light, and chemicals. It is widely employed in plastics, coatings, inks, and other manufacturing processes where vibrant, durable green coloration is required.

Pearlizer

Pearlizer (UFABLEND) is a specialized additive designed to impart a lustrous, pearlescent finish to a variety of coatings, paints, cosmetics, and plastics. It enhances the aesthetic appeal by creating shimmering and iridescent effects through the controlled dispersion of mica, titanium dioxide, or other pearlescent pigments. Pearlizer (UFABLEND) offers excellent compatibility with different formulations, providing stability and improved visual effects.

Pigment Orange

Pigment Orange is a concentrated dispersion of synthetic orange pigment particles in a suitable carrier, designed to deliver bright, vivid orange coloration. It offers excellent stability, heat resistance, and chemical inertness, making it suitable for diverse industrial applications including paints, plastics, inks, and coatings. This pigment ensures consistent color strength and durability across a variety of substrates.

Strawberry Red Pigment

Strawberry red pigment is a concentrated synthetic pigment dispersion providing a bright and vivid strawberry-red coloration. Known for its excellent lightfastness, chemical resistance, and thermal stability, it is widely used in paints, coatings, plastics, inks, and specialty industrial applications. The pigment ensures consistent color strength and durability across multiple manufacturing processes and substrates.

Tomato Red Dye

Tomato Red Dye is a synthetic azo dye prized for its vibrant, bright red coloration and excellent water solubility. It delivers consistent, vivid red shades that are stable under a variety of environmental conditions, including exposure to light, heat, and washing. This dye is extensively used across multiple industries including food and beverage, cosmetics, pharmaceuticals, and textiles. In food applications, it enhances the visual appeal of products such as beverages, confectionery, sauces, and baked goods. Its compatibility with different formulation types and regulatory approvals make it a reliable choice for cosmetic products like lipsticks, blushes, and nail polishes, as well as pharmaceutical tablets and syrups for identification and aesthetic purposes. The dye's superior performance, combined with strict adherence to safety and quality standards, ensures that it meets the requirements of manufacturers and regulatory bodies worldwide.

Waxol Solvent Red

Waxol Solvent Red is a synthetic dye primarily used for coloring hydrocarbon-based products. It is a solvent-soluble red dye known for its excellent color strength, stability, and compatibility with various waxes, oils, plastics, and fuels. This dye is widely employed in industries requiring vibrant red coloration of non-polar materials, providing consistent performance under different processing conditions.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders