Lead Drier

Whatsapp Order

Lead Drier is a chemical additive primarily used in the coatings and paints industry to accelerate the drying and curing process of oil-based paints, varnishes, and coatings. It functions as a catalytic agent that promotes the oxidative polymerization of drying oils, reducing the drying time and improving the film formation. Lead driers are traditionally lead-based salts such as lead naphthenate or lead octoate, valued for their effectiveness at low concentrations. Due to toxicity concerns, their use is increasingly regulated and often replaced by safer alternatives.

Categories: Driers, Additives, Catalysts

Tags: Lead Drier, Lead-Based Drier, Metallic Drier, Oxidation Catalyst, Paint Drier, Paint Hardener

Description

Table of Contents

Toggle

Lead Drier

Primary Uses

- Paints and Coatings Industry

- Accelerates drying of alkyd and oil-based paints and varnishes to improve productivity.

- Enhances hardness and durability of the dried paint film by promoting even curing.

- Used in primers, enamels, and industrial coatings to reduce tackiness and improve surface finish.

- Printing Inks

- Acts as a drying agent in certain ink formulations to reduce drying time and prevent smudging.

- Wood Finishing

- Speeds up drying of wood stains and varnishes, aiding in quicker processing and handling.

Secondary Uses

- Artist Paints

- Sometimes used in oil paints by artists to control drying times and improve workability.

- Adhesives and Sealants

- Incorporated into some solvent-based adhesives to hasten cure and set times.

- Industrial Applications

- Used as a catalyst in some polymer and resin curing processes where drying speed is critical.

PRODUCT KEY FEATURES

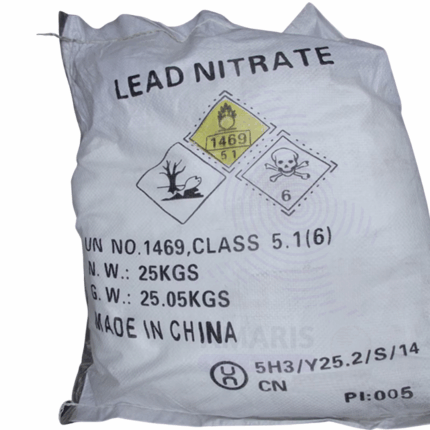

- Basic Identification Attributes

- Chemical Name (IUPAC): Lead (II) octoate or Lead naphthenate (varies by type)

- Common/Trade Name: Lead Drier; Lead Octoate; Lead Naphthenate

- CAS Number: Varies (e.g., Lead octoate ~ 301-02-0)

- HS Code: 2833.29.00 (Other lead compounds)

- Synonyms: Lead drying agent; drying accelerator; paint drier

- Physical & Chemical Properties

- Physical State: Viscous liquid or paste

- Color & Odor: Yellow to brownish; characteristic mild odor

- Solubility: Soluble in oils, solvents; insoluble in water

- Melting Point: Variable depending on formulation

- Density: Approx. 1.0 – 1.2 g/cm³

- Safety & Hazard Attributes

- GHS Classification: Toxic; harmful if swallowed or inhaled; causes skin and eye irritation; may cause long-term health effects

- Toxicity: Lead compounds are toxic and pose risks of lead poisoning with chronic exposure

- Exposure Limits: OSHA PEL for lead: 50 µg/m³ (airborne lead)

- Storage & Handling Attributes

- Storage Conditions: Store in tightly sealed containers in a cool, dry, well-ventilated area away from incompatible substances

- Container Type: Metal or heavy-duty plastic drums/containers resistant to corrosion

- Shelf Life: Typically 1-2 years if stored properly

- Handling Precautions: Use appropriate PPE including gloves, respiratory protection, and avoid inhalation or skin contact

- Regulatory & Compliance Attributes

- Subject to strict regulations due to lead toxicity (e.g., OSHA, REACH, EPA)

- Use restricted or banned in many countries for consumer products

- Must be labeled with hazard warnings and handled according to hazardous material guidelines

- Environmental & Health Impact

- Biodegradability: Not biodegradable; persists in the environment

- Ecotoxicity: Highly toxic to aquatic life; bioaccumulative

- Bioaccumulation: Lead accumulates in biological systems, posing environmental hazards

- Carcinogenicity/Mutagenicity: Classified as probable human carcinogen; causes reproductive toxicity

SAFETY HANDLING PRECAUTIONS

- Safety Handling Precautions

- PPE Required: Chemical-resistant gloves, protective clothing, eye protection, and respiratory protection in confined spaces

- Handling Guidelines: Use in well-ventilated areas or under fume extraction; avoid ingestion and inhalation

- Storage Measures: Store away from acids, oxidizers, and incompatible materials; prevent leaks and spills

- First Aid Measures

- Inhalation: Move to fresh air immediately; seek medical attention if symptoms occur

- Skin Contact: Wash affected area with soap and water; remove contaminated clothing; seek medical advice if irritation persists

- Eye Contact: Rinse eyes thoroughly with water for at least 15 minutes; obtain medical attention

- Ingestion: Do not induce vomiting; rinse mouth and seek urgent medical attention

- Firefighting Measures

- Fire Hazards: Combustible; may emit toxic fumes of lead and other hazardous gases when heated

- Extinguishing Media: Use dry chemical, foam, or CO2 extinguishers; avoid water streams that may spread contamination

- Special Precautions: Firefighters should wear full protective gear and self-contained breathing apparatus

- Hazardous Combustion Products: Lead oxides, carbon monoxide, carbon dioxide

Related products

Dicumyl Peroxide

Dicumyl Peroxide (DCP) is a widely used organic peroxide with powerful free radical initiator properties. It appears as a white crystalline solid with a characteristic odor and is primarily employed as a cross-linking agent and polymerization initiator in the plastics and rubber industries. Due to its ability to generate free radicals upon thermal decomposition, it facilitates curing and cross-linking of polymers, improving mechanical properties and heat resistance. Dicumyl Peroxide is a key component in manufacturing processes for polyethylene, polypropylene, EPDM rubber, and other elastomers.

Diethyl Phthalate

Diethyl Phthalate is a high-purity, colorless, oily liquid with a faint, sweet aromatic odor. With a minimum of 99% active content, DEP 99% is a trusted solvent and plasticizer that offers excellent stability, low volatility, and high compatibility with a wide range of organic and polymeric materials. It is widely used in the cosmetic, pharmaceutical, plastics, coatings, and fragrance industries where purity is critical for both performance and safety. Its mild toxicological profile and solvency characteristics make it a versatile component in numerous sensitive and industrial applications.

Domacryl 251 50X

Domacryl is a high-performance acrylic polymer latex designed for use as a binder in water-based coatings, adhesives, sealants, and construction materials. It is a styrene-acrylic copolymer emulsion offering excellent film formation, adhesion, durability, and chemical resistance. Domacryl provides superior mechanical strength and flexibility in formulated products, making it ideal for applications requiring long-lasting protection and enhanced aesthetic qualities. The polymer is supplied as a stable aqueous dispersion with approximately 50% solids content, packed in bulk (190 kg drums) for industrial use.

Emulsifier (Emulgator)

Emulsifier is a nonionic surfactant belonging to the family of Nonylphenol Ethoxylates (NPEs), specifically with an average of 9 ethylene oxide (EO) units. It is widely used as an effective emulsifying, wetting, dispersing, and solubilizing agent. NP-9 is typically a pale yellow to amber viscous liquid, soluble in water and various organic solvents. It is valued for its strong emulsifying ability to stabilize oil-in-water (O/W) and water-in-oil (W/O) emulsions, excellent detergency, and good compatibility with other surfactants and formulation ingredients. NP-9 is commonly employed in industrial, agricultural, cosmetic, pharmaceutical, and cleaning applications.

Hycryl

Hycryl is a specialized acrylic copolymer resin designed primarily for industrial and cosmetic applications. It appears as a white to off-white powder or granules with excellent film-forming, adhesive, and thickening properties. Known for its compatibility with a wide range of solvents and plasticizers, Hycryl 77 provides excellent clarity, flexibility, and durability in coatings, adhesives, and personal care formulations. Its balanced molecular weight and functional groups enable it to deliver strong binding and aesthetic properties in both aqueous and solvent-based systems.

Hydrochloric Acid HCL

Hydrochloric Acid HCL is a highly corrosive, strong mineral acid consisting of hydrogen chloride gas dissolved in water to a concentration of approximately 33% by weight. It appears as a clear, colorless to slightly yellow liquid with a sharp, pungent odor. HCl 33% is widely used in industrial, chemical, and laboratory applications due to its strong acidic properties, high reactivity, and versatility. It plays a crucial role in pH control, metal processing, chemical synthesis, and cleaning processes across numerous sectors.

Rubber Accelerator MBTS

Rubber Accelerator MBTS (Mercaptobenzothiazole Disulfide) is a crucial chemical used in the vulcanization process of rubber. It accelerates the cross-linking of rubber molecules, enhancing the elasticity, strength, and durability of the final rubber products. MBTS is favored for its effective acceleration properties and is widely used in the production of tires, footwear, hoses, and various rubber goods.

Zicronium Octoate

Zirconium Octoate is a metal carboxylate solution comprising zirconium ions complexed with octoic acid at an 18% zirconium concentration. It serves as an effective crosslinking and curing agent in coatings, adhesives, and sealants, enhancing film hardness, chemical resistance, and durability. This zirconium-based additive is valued for its catalytic properties in accelerating the curing of various polymer systems, especially in automotive and industrial applications.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders