Anti Foam

Whatsapp Order

Anti foams are chemical additives designed to reduce or prevent the formation of foam in industrial processes, manufacturing, and various formulations. Foam can interfere with operations such as mixing, filling, pumping, and heat transfer, leading to reduced efficiency or defects in products. Anti foams work by destabilizing foam bubbles, causing them to coalesce and collapse rapidly. They are widely used in industries including food and beverage, pharmaceuticals, wastewater treatment, paints and coatings, and chemical manufacturing. Different types of anti foams include silicone-based, mineral oil-based, and organic polymer-based formulations, chosen according to the specific application and process conditions.

Description

Table of Contents

Toggle

Anti foam

Primary Uses

- Food & Beverage Industry

- Used to control foam during the processing of beer, soft drinks, juices, and dairy products to ensure smooth operation and consistent quality.

- Pharmaceutical Manufacturing

- Helps maintain proper mixing and processing by preventing foam formation in liquid medicines, syrups, and suspensions.

- Wastewater Treatment

- Controls foam in aeration tanks and sludge processing to enhance treatment efficiency and prevent overflow or equipment damage.

- Paints & Coatings

- Reduces foam during production and application of paints, varnishes, and inks to improve finish quality and prevent defects.

- Chemical Processing

- Prevents foam build-up in reactors, distillation columns, and other equipment where foaming can disrupt operation or cause safety issues.

Secondary Uses

- Textile Industry

- Controls foam in dyeing and finishing processes to improve fabric quality.

- Oil & Gas

- Used in drilling fluids and refining processes to reduce foam formation.

- Cosmetics & Personal Care

- Sometimes incorporated in formulations to regulate foam characteristics in shampoos and cleansers.

KEY PRODUCT FEATURES

1. Basic Identification Attributes

- Chemical Name (IUPAC): Varies depending on active ingredient (e.g., polydimethylsiloxane for silicone-based anti foams)

- Common/Trade Name: Anti Foam, Defoamer

- CAS Number: Varies by chemical composition

- HS Code: 3402.90.90 (varies by product and region)

- Molecular Formula: Depends on chemical composition (silicone oils, mineral oils, etc.)

- Synonyms: Defoamer, foam suppressant

2. Physical & Chemical Properties

- Physical State: Usually liquid or paste; some powdered forms exist

- Color & Odor: Colorless to pale yellow; typically odorless or mild odor depending on formulation

- Solubility: Insoluble or partially soluble in water; soluble in oils and organic solvents depending on type

- Density: Typically between 0.8 to 1.2 g/cm³

- Stability: Chemically stable under normal storage and use conditions

3. Safety & Hazard Attributes

- Hazard Class (GHS): Generally low hazard; may be classified depending on specific formulation components

- Exposure Limits: Varies; follow MSDS for specific products

- Reactivity: Stable; avoid strong oxidizers or extreme conditions

4. Storage & Handling Attributes

- Storage Conditions: Store in cool, dry place away from heat and ignition sources

- Container Type: Typically supplied in plastic drums, metal cans, or bottles

- Shelf Life: Typically 1–3 years depending on formulation and storage conditions

- Special Handling: Avoid prolonged skin contact; use PPE as per safety data sheet

5. Regulatory & Compliance Attributes

- Regulatory Status: Approved for use in food processing and pharmaceuticals when food-grade quality is specified

- Transportation: Generally not classified as hazardous; comply with local transport regulations

- Waste Disposal: Dispose in accordance with local environmental regulations

6. Environmental & Health Impact

- Ecotoxicity: Low toxicity when used as intended; biodegradable properties depend on formulation

- Persistence: Some formulations may be persistent in environment; biodegradable variants preferred

- Carcinogenicity: Not classified as carcinogenic

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- PPE: Use gloves and goggles to prevent skin and eye contact.

- Ventilation: Use in well-ventilated areas to avoid inhalation of vapors or aerosols.

- Spill Management: Clean spills promptly with absorbent materials; avoid release to waterways.

- Hygiene: Wash hands after handling; do not eat, drink, or smoke in work areas.

First Aid Measures

- Inhalation: Move to fresh air; seek medical attention if breathing is difficult.

- Skin Contact: Wash with soap and water; remove contaminated clothing; seek medical advice if irritation occurs.

- Eye Contact: Rinse eyes thoroughly with water for at least 15 minutes; seek medical help if irritation persists.

- Ingestion: Rinse mouth; do not induce vomiting; seek medical attention if large amounts ingested.

Firefighting Measures

- Fire Hazards: Generally low flammability; may burn if exposed to high heat or flame.

- Extinguishing Media: Use water spray, foam, dry chemical, or CO₂ extinguishers as appropriate.

- Special Precautions: Firefighters should wear protective gear and self-contained breathing apparatus if exposure to fumes is possible.

Related products

Acrytan SN

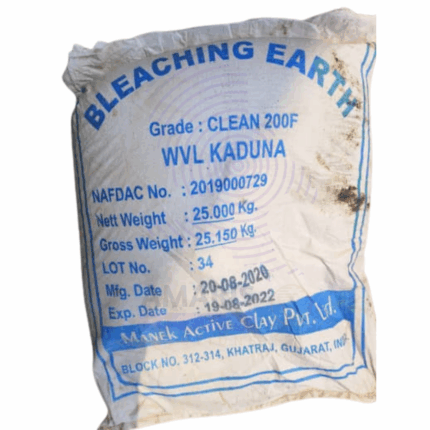

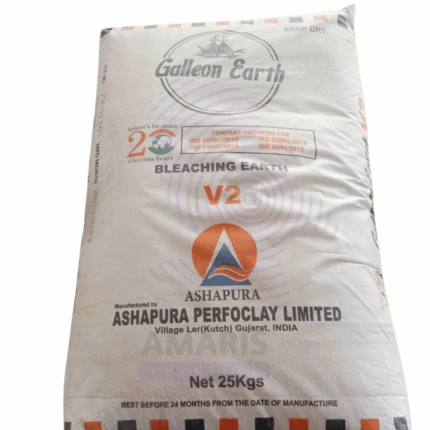

Bleaching Earth

Bleaching Earth is a fine, highly adsorptive clay material derived primarily from bentonite or montmorillonite, and in some cases from attapulgite or sepiolite. It is typically activated using acid treatment to enhance its surface area and pore structure. It is widely used to remove color, contaminants, impurities, and odors from edible oils, fats, waxes, petroleum products, and various industrial fluids. Its high adsorption capacity, non-toxic nature, and effectiveness in filtration make it essential in food processing, chemical industries, cosmetics, and waste treatment applications.

Calcium Chloride

Calcium Chloride is an inorganic salt composed of calcium and chlorine with the chemical formula CaCl₂. It typically appears as a white crystalline solid or granular powder, highly soluble in water and exhibiting strong hygroscopic properties. Calcium Chloride is widely used for its moisture-absorbing ability, de-icing, dust control, and as a firming agent in food processing. It finds extensive applications across industrial, pharmaceutical, agricultural, and food sectors due to its efficacy in modifying physical and chemical properties of products and environments.

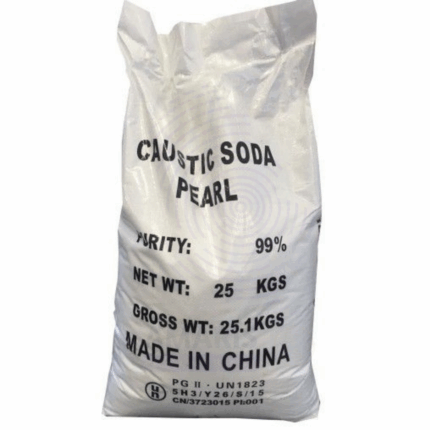

Caustic Soda Pearls

Caustic Soda Pearls are small, solid, spherical particles of sodium hydroxide (NaOH) produced by a controlled cooling and solidification process. These pearls offer superior flowability, uniform size distribution, and reduced dust generation compared to flake or powder forms. They are highly soluble in water, exhibiting a strong alkaline nature with vigorous exothermic dissolution. Caustic Soda Pearls are widely used across industries including chemical manufacturing, water treatment, pulp and paper processing, and detergents due to their purity, ease of handling, and efficient dissolution characteristics.

Cobalt Drier

Cobalt Drier is a metal-based drying agent primarily composed of cobalt salts (commonly cobalt octoate or cobalt naphthenate). It is widely used as a catalyst to accelerate the drying (oxidative curing) of oils, alkyd resins, and varnishes in coatings and paints. This drier promotes polymerization and cross-linking of unsaturated fatty acids in drying oils upon exposure to air, significantly reducing drying times and improving film hardness and durability. Cobalt driers are essential additives in industrial, decorative, and automotive coatings due to their effectiveness at low concentrations and compatibility with various resin systems.

Defoamer

Defoamer is a high-performance, silicone-based antifoaming agent designed to eliminate and prevent foam formation in aqueous and non-aqueous systems. It is typically a milky-white or translucent emulsion composed of modified polydimethylsiloxane, hydrophobic silica, and proprietary surfactants or emulsifiers. Defoamer is known for its immediate foam knockdown, long-lasting suppression, and compatibility across diverse formulations. It is widely used in industrial processes, coatings, adhesives, water treatment, textiles, and more. It is effective at low concentrations, thermally stable, and resistant to shear and pH fluctuations.

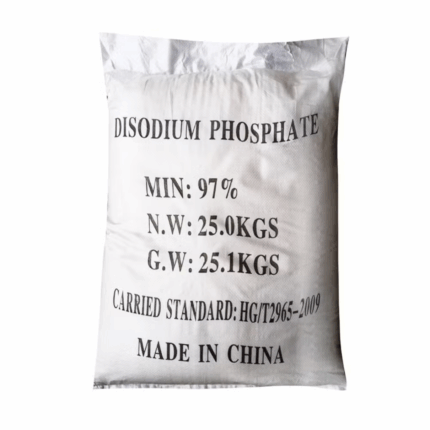

Disodium Phosphate

Disodium Phosphate, also known as sodium phosphate dibasic, is an inorganic compound widely used for its buffering, emulsifying, and chelating properties. It commonly appears as a white, odorless crystalline powder or granules that are highly soluble in water and alkaline in nature. Disodium Phosphate plays a vital role in regulating pH, improving stability in formulations, and providing essential sodium and phosphate ions. It finds extensive use across food processing, pharmaceuticals, water treatment, agriculture, and industrial applications.

Solvent Orange

Solvent Orange is a synthetic azo dye widely used for coloring oils, waxes, plastics, and other non-polar substrates. It appears as an orange-red powder or granules and exhibits excellent solubility in organic solvents and oils, delivering bright, durable coloration. Packaged in a 25kg drum, this dye is favored in industrial applications requiring vibrant orange hues in solvent-based systems.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders