Polyvinyl Chloride Resin 701

Whatsapp Order

Polyvinyl Chloride Resin 701 is a high-quality suspension-grade polyvinyl chloride resin with a K-value of approximately 70–71, indicating high molecular weight. It is widely used in the production of flexible PVC products where excellent strength, elongation, and plasticizer absorption are required. PVC Resin 701 offers superior mechanical properties, high thermal stability, and good compatibility with plasticizers, making it suitable for calendaring, extrusion, and molding applications in diverse industries.

Description

Table of Contents

Toggle

Polyvinyl Chloride Resin 701 (PVC)

Primary Uses

- Flexible PVC Products

- Used in making cables, wires, hoses, and tubing due to its excellent flexibility and plasticizer compatibility.

- Ideal for synthetic leather and flooring where softness, strength, and durability are essential.

- Employed in production of raincoats, boots, and inflatable items requiring elongation and softness.

- Calendaring Applications

- Applied in the production of flexible films, sheets, and decorative foils.

- Used in wall coverings, upholstery, and tablecloths requiring a smooth, printable surface.

- Extrusion Applications

- Utilized in manufacturing soft tubing for medical and industrial use.

- Applied in flexible conduit systems and protective coverings for mechanical and electrical components.

- Dipping and Coating Applications

- Used in glove manufacturing (industrial and medical) through plastisol dipping.

- Employed in coatings for tool handles, safety equipment, and textiles.

- Injection Molding

- Applied in soft, flexible molded items like gaskets, seals, and footwear components.

Secondary Uses

- Medical Applications (Flexible Grade)

- Used in non-critical components like blood bags, IV tubing, and oxygen masks (depending on purity and formulation).

- Toys and Childcare Products

- Applied in the production of soft toys and teething items with appropriate stabilizers.

- Automotive Interiors

- Used in dashboard skins, seat covers, and door panel coatings for flexible, weather-resistant surfaces.

- Adhesives and Sealants

- Added in formulation of PVC-based sealants and adhesives to improve elasticity and adhesion.

- Textile Coating

- Used in manufacturing waterproof fabrics, tarpaulins, and awnings.

KEY PRODUCT FEATURES

1. Basic Identification Attributes

- Chemical Name (IUPAC): Poly(chloroethene) or Polyvinyl chloride

- Common/Trade Name: PVC Resin 701

- CAS Number: 9002-86-2

- HS Code: 3904.10.00

- Synonyms: Flexible-grade PVC resin, High K-value PVC

2. Physical & Chemical Properties

- Physical State: Fine white powder

- Color & Odor: White; odorless

- K-Value: 70–71

- Bulk Density: ~0.45–0.55 g/cm³

- Plasticizer Absorption: High (due to high molecular weight)

- Solubility: Insoluble in water; compatible with plasticizers and organic solvents

3. Safety & Hazard Attributes

- GHS Classification: Not hazardous in solid form; harmful gases if decomposed

- Toxicity: Low under normal use; avoid inhaling dust or fumes from heating

- Exposure Limits: Use engineering controls to minimize airborne dust during handling

4. Storage & Handling Attributes

- Storage Conditions: Store in a dry, cool, well-ventilated area away from heat and ignition sources

- Container Type: 25 kg paper or PE-lined bags; bulk sacks or silos

- Shelf Life: Indefinite under proper storage conditions

- Handling Precautions: Minimize dust; use local exhaust ventilation

5. Regulatory & Compliance Attributes

- May comply with FDA, RoHS, and REACH depending on additive systems used

- Suitable for food contact and medical-grade applications if properly formulated

- Manufactured in ISO and GMP-certified facilities

6. Environmental & Health Impact

- Biodegradability: Not biodegradable

- Ecotoxicity: Low in solid form; avoid release of dust into environment

- Bioaccumulation: Not expected

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- PPE Required: Use dust mask or respirator, gloves, goggles, and protective clothing

- Handling Guidelines: Avoid dust formation; use in ventilated or controlled environments

- Storage Measures: Keep containers tightly closed and stored in a dry environment

First Aid Measures

- Inhalation: Move to fresh air; seek medical attention if symptoms persist

- Skin Contact: Wash exposed skin with soap and water

- Eye Contact: Rinse thoroughly with water for 15 minutes; consult physician if irritation continues

- Ingestion: Rinse mouth; do not induce vomiting; seek medical advice

Firefighting Measures

- Fire Hazards: Not flammable; decomposes at high temperatures releasing toxic fumes

- Extinguishing Media: Use water spray, dry chemical, foam, or CO₂

- Special Precautions: Wear self-contained breathing apparatus and protective clothing

- Hazardous Combustion Products: Hydrogen chloride gas, carbon monoxide, and carbon dioxide

Related products

Adipic Acid

$ 3.20

HDPE Blow HDB5502

HDPE Blow HDB5502 is a high-density polyethylene resin specifically formulated for blow molding applications. It is a semi-crystalline thermoplastic polymer characterized by excellent strength-to-density ratio, high chemical resistance, and superior processability in blow molding equipment. This grade exhibits high stiffness, good environmental stress crack resistance (ESCR), and excellent impact resistance, making it ideal for manufacturing durable hollow containers and complex-shaped products. The resin is supplied as granular pellets with consistent melt flow and homogeneity, optimized for efficient molding cycles and high throughput.

LLDPE film Opalene F20015

LLDPE film Opalene F20015 is a high-quality linear low-density polyethylene (LLDPE) film known for its excellent clarity, toughness, and flexibility. It is produced using linear low-density polyethylene resin, offering superior mechanical properties and puncture resistance compared to conventional low-density polyethylene films. Opalene F20015 is widely used in packaging applications where strength, transparency, and sealability are critical. Its balanced properties make it suitable for various industrial and consumer packaging needs.

Melamine

Melamine is an organic compound widely used as a raw material in the production of melamine-formaldehyde resins, laminates, adhesives, coatings, and flame retardants. It offers excellent hardness, thermal stability, and chemical resistance. Supplied in 25kg bags, melamine is a white crystalline powder with high nitrogen content, making it a valuable additive in plastics, construction materials, and surface treatments.

Polyvinyl Chloride Masterbatch

Polyvinyl Chloride Masterbatch is a concentrated mixture of pigments, additives, or fillers encapsulated in a PVC carrier resin, designed for direct addition into PVC processing applications. It offers an efficient and dust-free way to color, modify, or enhance the physical properties of PVC products. This masterbatch ensures excellent dispersion, consistent coloration, and improved processability. It is widely used in rigid and flexible PVC applications including construction, automotive, packaging, electrical, and consumer products.

Polyvinyl Chloride PE Wax

Polyvinyl Chloride PE Wax is a polyethylene-based wax additive used in PVC formulations to improve processing, lubrication, and surface finish. It serves as an internal and external lubricant in both rigid and flexible PVC products, enhancing extrusion, molding, and calendaring operations. It also contributes to better dispersion of fillers and pigments, reduced friction, and improved thermal stability. PE Wax for PVC is available in powder, flake, or granule form and is valued for its compatibility, thermal resistance, and cost-effectiveness.

Polyvinyl Chloride Resin

Polyvinyl Chloride Resin is a white, odorless powder widely used as the base material in the production of both rigid and flexible PVC products. It is produced by polymerizing vinyl chloride monomer (VCM) and is categorized by K-value, which defines molecular weight and processing characteristics. PVC resin is valued for its durability, chemical resistance, electrical insulation, and flame retardancy. It is one of the most versatile plastics used across multiple industries including construction, electrical, automotive, packaging, and healthcare.

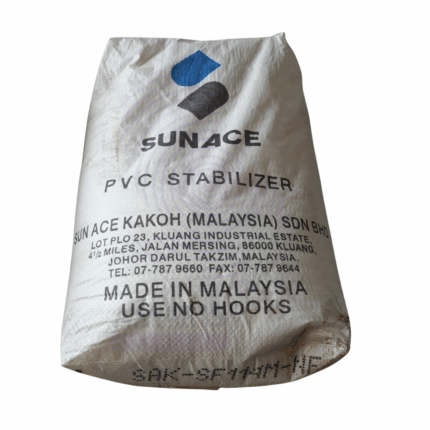

Polyvinyl Chloride Stabilizer

Polyvinyl Chloride Stabilizer is a crucial additive used in the processing of polyvinyl chloride (PVC) to protect it from thermal degradation during manufacturing and throughout its service life. It ensures color stability, prevents chain scission, and enhances the durability of PVC products exposed to heat, light, and mechanical stress. PVC stabilizers are available in various types, including lead-based, calcium-zinc (Ca-Zn), organotin, and mixed metal stabilizers, each suited for different applications depending on regulatory, environmental, and performance requirements.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders