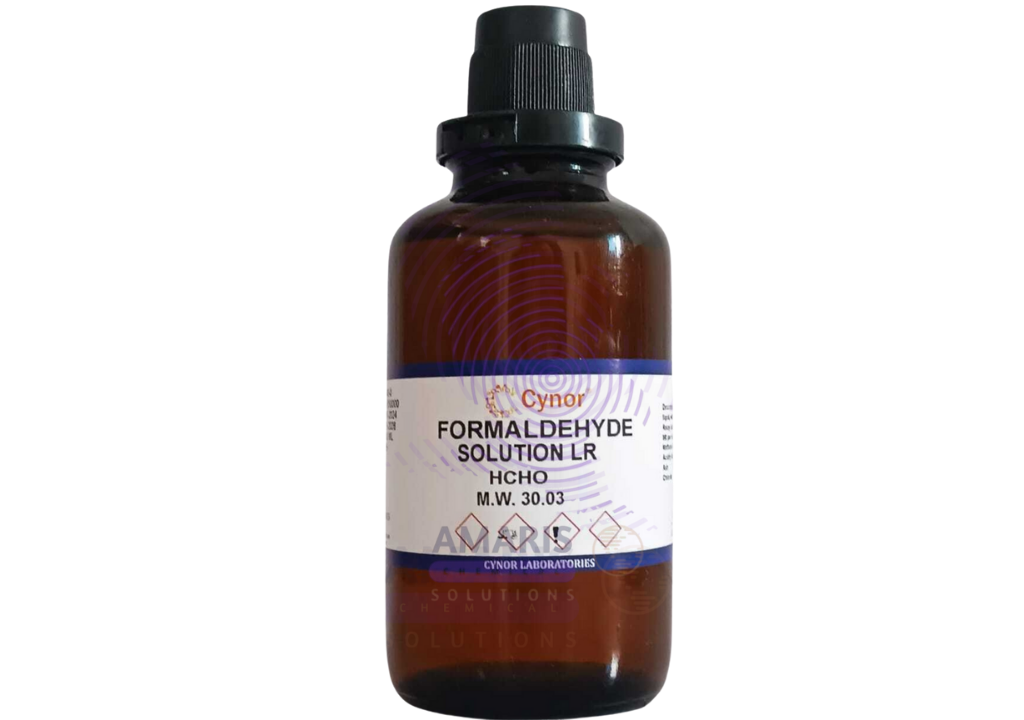

🧪 Formaldehyde Extra Pure: The Backbone of Modern Chemistry and Industrial Innovation

Few chemicals have influenced science and industry as profoundly as Formaldehyde Extra Pure. From preserving biological specimens to strengthening building materials, this compound’s versatility has made it a cornerstone in laboratories and manufacturing facilities around the world.

At Amaris Chemical Solutions, we believe in helping industries understand the science behind their materials — not just how to use them, but why they matter. So, let’s explore the fascinating world of formaldehyde: what it is, where it’s used, and how it’s safely managed in modern chemical applications. 🌍

⚗️ What is Formaldehyde Extra Pure?

Formaldehyde (CH₂O) is a colorless, strong-smelling gas, usually available in aqueous solution form — commonly known as formalin. The “extra pure” grade indicates a high level of chemical purity, making it suitable for analytical, laboratory, and precision applications where impurities could interfere with results.

This compound is one of the simplest aldehydes and plays a crucial role as a building block in organic synthesis. It’s highly reactive, which makes it incredibly useful in forming polymers, resins, and many industrial chemicals.

🔬 Key Laboratory and Industrial Applications

Formaldehyde Extra Pure serves diverse purposes across scientific and industrial sectors. Let’s take a closer look at how it’s applied:

1. Preservation and Fixation in Laboratories

Formaldehyde is famously known for its use in preserving biological specimens. It crosslinks proteins, effectively “freezing” cells and tissues in their natural state for microscopic study. In histology and pathology, it’s indispensable for sample fixation.

2. Resin and Plastic Manufacturing

One of the most significant industrial uses of formaldehyde is in the production of urea-formaldehyde, phenol-formaldehyde, and melamine-formaldehyde resins. These resins are found in plywood, particle board, coatings, and laminates, contributing strength and water resistance.

3. Disinfectant and Sterilizing Agent

Due to its strong antibacterial and antifungal properties, formaldehyde is used as a disinfectant in laboratories, hospitals, and manufacturing facilities. It helps sterilize surfaces, equipment, and even air in controlled environments.

4. Intermediate in Chemical Synthesis

Formaldehyde acts as a key raw material for producing various chemicals such as hexamine, pentaerythritol, and 1,4-butanediol — compounds essential in plastics, coatings, and explosives manufacturing.

5. Agricultural and Textile Uses

In agriculture, it’s used in fertilizer formulations and seed disinfection, while in textiles, it improves fabric wrinkle resistance and dimensional stability.

⚠️ Safety and Handling Precautions

Formaldehyde is highly reactive and can be hazardous if not handled with care. Here are essential safety measures to keep in mind:

- Always work in well-ventilated areas or under a fume hood.

- Use chemical-resistant gloves, lab coats, and eye protection.

- Avoid inhalation of vapors and direct skin contact.

- Store in tightly closed containers, away from heat and oxidizing agents.

- Label containers clearly and handle with proper chemical waste protocols.

In case of contact:

- Skin: Wash immediately with soap and water.

- Eyes: Rinse thoroughly with clean water for at least 15 minutes and seek medical attention.

- Inhalation: Move to fresh air and get medical assistance if breathing difficulty occurs.

🌿 Environmental and Health Considerations

Formaldehyde is a volatile organic compound (VOC) and is classified as a hazardous substance due to its potential health effects at high concentrations. However, when managed responsibly, it remains one of the most efficient and controlled substances in scientific use.

Industries and laboratories today use closed systems, proper exhaust setups, and strict monitoring to minimize environmental emissions and worker exposure. This ensures that its benefits can be harnessed safely and sustainably.

At Amaris Chemical Solutions, we promote the responsible handling and education surrounding formaldehyde use — balancing innovation with health and environmental awareness. 🌱

💡 Why Formaldehyde Extra Pure Matters

In chemistry, purity determines precision. Formaldehyde Extra Pure ensures consistent reactivity and reliability in analytical and experimental applications. Whether you’re formulating new resins, preparing biological samples, or conducting controlled syntheses, this chemical guarantees accuracy and performance you can trust.

It’s more than just a reagent — it’s a foundation for innovation, driving advancements in materials science, biology, and industrial chemistry.

✨ Final Thoughts

Formaldehyde Extra Pure continues to be an essential player in modern science and industry. Its unique properties make it both powerful and indispensable — provided it’s used with knowledge, care, and respect for safety.

Through responsible sourcing, expert handling, and high purity standards, we help industries harness the best of what chemistry has to offer. Every molecule matters — and in the case of formaldehyde, it’s a molecule that continues to shape the future of innovation. 💧🔬

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders