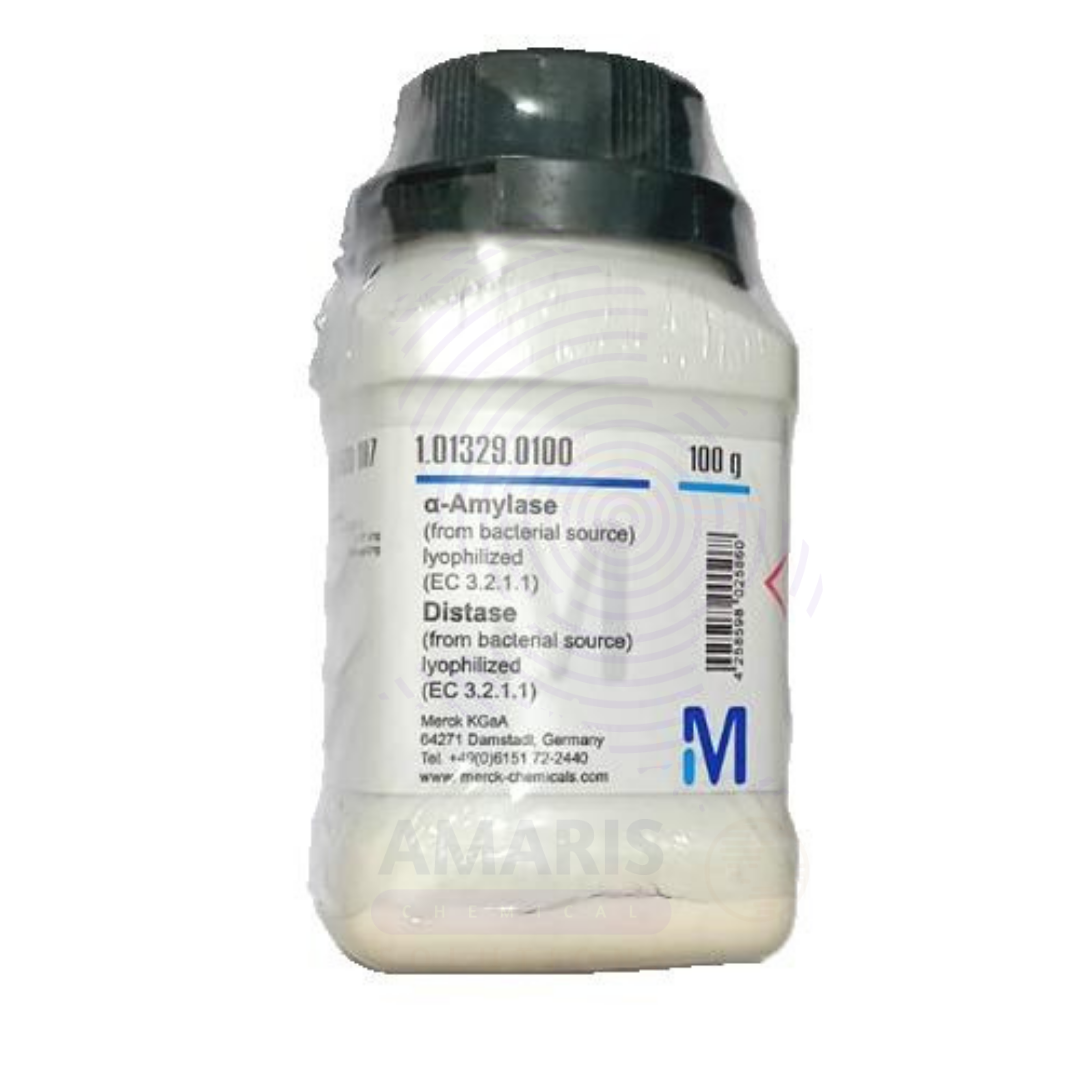

Amylase Extra Pure

$ 19.00 Original price was: $ 19.00.$ 18.45Current price is: $ 18.45.

Amylase Extra Pure is a high-purity enzyme preparation used extensively in laboratory settings for biochemical, enzymatic, and molecular biology research. It catalyzes the hydrolysis of starch into simpler sugars like maltose and glucose, making it essential in studies of carbohydrate metabolism, enzyme kinetics, and digestive processes. Its extra pure grade ensures minimal non-enzymatic contaminants, providing consistent and reliable performance in sensitive assays, substrate specificity tests, and educational experiments. Ideal for use in enzymology, food analysis, and biotechnology applications, amylase should be stored under cool, dry conditions—typically refrigerated or frozen—to preserve its enzymatic activity and stability.

Amylase Extra Pure

Primary Uses

- Enzymatic Breakdown of Starch

- Used to hydrolyze amylose and amylopectin into maltose, glucose, and dextrins in studies of carbohydrate metabolism.

- Enzyme Activity Assays and Kinetics

- Serves as a model enzyme in Michaelis–Menten kinetics, inhibition studies, and enzyme stability testing.

- Biochemical Research on Digestion and Metabolism

- Used in simulated digestion experiments or modeling the role of salivary or pancreatic amylase in starch processing.

- Component in Educational Enzyme Experiments

- Commonly used in student labs to demonstrate enzyme specificity, pH dependence, temperature effects, and denaturation.

- Preparation of Reducing Sugars for Analytical Testing

- Used in sample pretreatment for DNS (dinitrosalicylic acid) assays or Benedict’s tests to quantify sugars after hydrolysis.

Secondary Uses

- Substrate Preparation for Microbial Fermentation Studies

- Converts starch into fermentable sugars for growing yeasts or bacteria in fermentation modeling.

- Inhibitor Screening in Drug Discovery

- Applied in screening for alpha-amylase inhibitors, relevant in diabetes and metabolic disorder research.

- Study of Thermostability and Enzyme Engineering

- Used to investigate enzyme structure–function relationships, mutation effects, and thermostable enzyme design.

- Bioreactor and Immobilization Experiments

- Tested in enzyme immobilization protocols for continuous starch conversion in biochemical engineering.

- Quality Control in Food and Beverage Analysis

- Used in laboratory settings for measuring starch content or monitoring saccharification in brewing, baking, or syrup production.

| PACK SIZE |

25 grams Plastic Tin |

|---|

1. Basic Identification Attributes

- Chemical Name: Amylase (commonly refers to α-amylase)

- CAS Number: 9000-90-2 (for α-Amylase from various sources)

- HS Code: 35079090 (Enzymes and prepared enzymes, n.e.s.)

- Molecular Formula: Not a single formula – protein enzyme, varies by source (e.g., fungal, bacterial, or pancreatic origin)

- Synonyms:

- α-Amylase

- 1,4-α-D-glucan glucanohydrolase

- Diastase

- EC 3.2.1.1

2. Physical & Chemical Properties

- Physical State: Solid (lyophilized powder) or liquid (solution)

- Color & Odor: White to light beige powder; may have mild proteinaceous odor

- Boiling Point: Not applicable (denatures)

- Melting Point: Not applicable

- Density/Specific Gravity: Not defined (protein enzyme)

- Solubility:

- Water: Soluble

- Organic solvents: Insoluble

- pH Level: Active range typically 4.5–7.0, depending on enzyme source

- Optimal pH & Temperature:

- pH: ~5.5–6.5 (source-dependent)

- Temperature: ~30–65 °C (thermostability depends on origin)

- Vapor Pressure / Flash Point / Autoignition / Viscosity: Not applicable to enzyme preparations

3. Safety & Hazard Attributes

- Hazard Class (GHS):

- Respiratory Sensitizer (Category 1)

- May cause allergic skin or respiratory reaction (especially as inhalable powder)

- NFPA Ratings:

- Health: 1

- Flammability: 0

- Reactivity: 0

- Exposure Limits:

- No OSHA PEL; minimize inhalation

- Use in ventilated conditions to avoid respiratory sensitization

- Reactivity:

- Stable under proper storage

- Denatures rapidly under high heat or extreme pH

4. Storage & Handling Attributes

- Storage Conditions:

- Store at 2–8 °C (refrigerated); protect from light and moisture

- Avoid repeated freeze–thaw cycles for liquid forms

- Incompatible Materials:

- Strong acids/bases, oxidizers (may denature enzyme)

- Container Type:

- Glass or plastic vials with desiccant for powders

- Shelf Life & Expiration Date:

- 1–2 years under cold, dry conditions

- Special Handling Requirements:

- Wear gloves and mask when handling powders

- Avoid dust generation

5. Regulatory & Compliance Attributes

- Regulatory Status:

- GRAS (Generally Recognized as Safe) for food-grade forms

- Lab-grade: regulated for purity and enzyme activity

- Listed under REACH and TSCA

- Transportation Restrictions:

- Not regulated as hazardous for transport

- Waste Disposal Method:

- Biodegradable; small quantities may be disposed via drain with water

- Larger volumes: follow local biohazard enzyme disposal guidelines

6. Environmental & Health Impact

- Ecotoxicity:

- Low environmental toxicity

- Persistence in Environment:

- Rapidly degrades biologically

- Carcinogenicity/Mutagenicity:

- Not classified as carcinogenic

- Biodegradability:

- Fully biodegradable

SAFETY PRECAUTIONS

- Personal Protective Equipment (PPE):

- Wear a lab coat, safety goggles, and disposable gloves (e.g., nitrile or latex).

- Use a dust mask or operate under a fume hood if handling the enzyme in powdered form, as enzyme dust is a respiratory sensitizer.

- Handling:

- Avoid inhalation of powder or aerosol, especially in dry form.

- Prevent contact with eyes, skin, or clothing.

- Handle gently—enzymes are proteins and can become airborne easily.

- Storage:

- Store in a cool (2–8 °C for liquid or refrigerated powder), dry, and well-ventilated area.

- Keep container tightly closed and protected from moisture and light.

- Avoid temperature extremes to preserve enzyme activity.

- Hygiene Measures:

- Wash hands thoroughly after use.

- Do not eat, drink, or smoke in the lab.

- Clean surfaces after handling to remove residual protein.

FIRST AID MEASURES

- Inhalation:

- Remove the person to fresh air.

- If respiratory symptoms (coughing, wheezing, shortness of breath) occur, seek immediate medical attention—enzymes can cause allergic asthma or sensitization.

- Skin Contact:

- Wash skin thoroughly with soap and water.

- Remove contaminated clothing.

- Seek medical advice if irritation or allergic rash appears.

- Eye Contact:

- Rinse immediately with plenty of water for at least 15 minutes.

- Hold eyelids apart and remove contact lenses if present.

- Seek medical attention if irritation persists.

- Ingestion:

- Rinse mouth with water.

- Give water to drink if the person is conscious.

- Do not induce vomiting.

- Seek medical advice if large quantities are swallowed or if gastrointestinal symptoms appear.

FIRE FIGHTING MEASURES

- Suitable Extinguishing Media:

- Use water spray, dry chemical, foam, or carbon dioxide (CO₂).

- Specific Hazards:

- Not flammable, but combustion may produce:

- Carbon monoxide (CO)

- Carbon dioxide (CO₂)

- Nitrogen oxides (NOₓ) if proteinaceous dust is present

- Not flammable, but combustion may produce:

- Protective Equipment for Firefighters:

- Wear SCBA (self-contained breathing apparatus) and full protective gear.

- Firefighting Instructions:

- Avoid dispersing enzyme dust into the air.

- Use water spray to cool containers and suppress dust if involved in fire.

- Prevent runoff from entering drains—enzymes may disrupt aquatic biological processes.

Related products

Acetone Extra Pure

Aluminium Ferric Sulphate Extra Pure

Ammonium Carbonate Extra Pure

Ammonium Carbonate Extra Pure is a high-quality, white crystalline solid widely used across various scientific, industrial, and food-related applications. Manufactured to stringent purity standards, this compound is ideal for laboratories and processes that demand high-grade reagents. With its characteristic ammonia-like odor and ability to decompose upon heating, ammonium carbonate plays a versatile role in both chemical reactions and physical processes.

In aqueous solution, ammonium carbonate breaks down into ammonium bicarbonate and ammonium carbamate, further releasing ammonia (NH₃) and carbon dioxide (CO₂) upon heating. This property makes it especially useful in applications that require controlled gas release or temporary pH modification.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders