conical flask

$ 42.70 Original price was: $ 42.70.$ 42.57Current price is: $ 42.57.

Manganese Sulphate Extra Pure

$ 17.90 Original price was: $ 17.90.$ 17.78Current price is: $ 17.78.

Bar and Gauge Apparatus

$ 7.11 Original price was: $ 7.11.$ 7.06Current price is: $ 7.06.

Whatsapp Order

The Bar and Gauge Apparatus is a precision instrument used for measuring and comparing lengths, thicknesses, and distances in laboratory and industrial environments. It typically consists of calibrated bars, gauges, and scale components designed for accuracy in dimensional measurements. This apparatus is essential for quality control, calibration tasks, and research applications requiring precise measurement standards. Manufactured from durable materials such as stainless steel or hardened alloys, the Bar and Gauge Apparatus ensures reliable performance and longevity under regular use.

Description

Table of Contents

Toggle

Bar and Gauge Apparatus

Primary Uses

- Laboratory Applications

- Acts as the core elastic element in mechanical balances for measuring mass of samples, chemicals, and reagents.

- Used in calibration and repair of laboratory weighing instruments.

- Provides accurate force-to-displacement conversion in analytical balances.

- Facilitates precise mass measurement in experimental setups requiring manual weighing.

Secondary Uses

- Industrial Applications

- Integral component in industrial mechanical scales for raw material and product weight measurement.

- Used in maintenance and servicing of mechanical weighing equipment in production lines.

- Supports quality control processes by ensuring reliable weight measurements.

- Applied in mechanical pressure and force measuring devices in manufacturing environments.

KEY PRODUCT FEATURES

1.Basic Identification Attributes

- Instrument Type: Bar and Gauge Measuring Apparatus

- Material: Stainless steel, hardened alloy

- Function: Provides accurate length, thickness, and distance measurement

2.Physical & Chemical Properties

- Precision: High accuracy calibration marks and standards

- Durability: Resistant to wear and corrosion for long-term use

- Dimensions: Various sizes depending on application requirements

- Operating Environment: Suitable for controlled laboratory and industrial settings

3.Safety & Hazard Attributes

- Mechanical Risks: Potential for cuts or pinching during handling; use caution

- Toxicity: Non-toxic materials

- Allergens: None identified

4.Storage & Handling Attributes

- Storage Conditions: Store in protective cases to prevent damage and contamination

- Handling Precautions: Handle with care to maintain calibration integrity

5.Regulatory & Compliance Attributes

- Manufactured according to international measurement standards

- Quality controlled for laboratory and industrial precision requirements

6.Environmental & Health Impact

- Materials are recyclable

- Low environmental impact with proper disposal

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- Use protective gloves if handling sharp edges

- Avoid dropping or impact to preserve calibration accuracy

First Aid Measures

- Mechanical injury: Clean wounds and seek medical attention if necessary

Firefighting Measures

- Fire Hazard: Non-flammable metallic apparatus

- Extinguishing Media: Not applicable

- Special Precautions: None required

Related products

Burette Clamp

The Burette Clamp is a laboratory apparatus designed to securely hold burettes in place during titration and other volumetric procedures. Made from durable materials such as metal with rubber or plastic-coated grips, it ensures stability and prevents slippage or breakage. The clamp typically attaches to a retort stand or support rod, allowing hands-free operation and precise liquid dispensing.

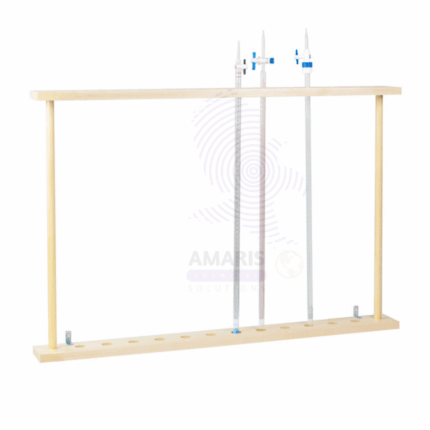

Burette stand for drying

The Burette Stand for Drying is a laboratory accessory designed to securely hold burettes in an upright position during drying and storage. Made from durable, corrosion-resistant materials such as stainless steel or coated metal, the stand ensures stability and prevents damage or contamination of delicate glassware. Its design facilitates proper air circulation, promoting efficient drying and maintaining the cleanliness of burettes between uses.

clinostat clock type

The Clinostat Clock Type is a precision laboratory instrument designed to simulate microgravity conditions by continuously rotating biological samples or small objects along a horizontal axis. This rotation counteracts the effect of gravity, allowing researchers to study the effects of weightlessness on plant growth, cell cultures, and other biological specimens. Constructed with durable materials and calibrated for smooth, consistent rotation, the Clinostat Clock Type is widely used in botanical, microbiological, and space biology research.

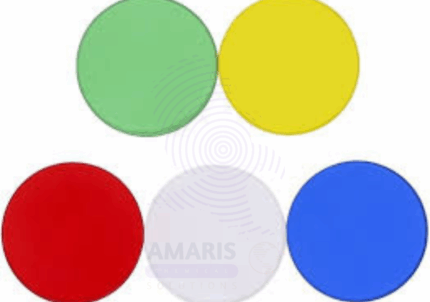

Color Filters

Color Filters are optical components designed to selectively transmit light of specific wavelengths while absorbing or reflecting others. These filters are used in various laboratory and industrial applications to isolate particular colors for scientific experiments, photography, microscopy, and optical analysis. Manufactured from high-quality glass or plastic materials, color filters ensure consistent performance with minimal distortion and high durability.

Desiccators with Knob

Desiccators with Knob are specialized laboratory containers designed to preserve moisture-sensitive materials by providing a dry, airtight environment. Constructed from high-quality borosilicate glass or durable plastic, these desiccators feature a tightly sealed lid with a central knob for easy handling and secure closure. The knob allows convenient lifting and placement of the lid without compromising the internal vacuum or dry atmosphere. Commonly used with desiccant agents like silica gel, they are ideal for drying samples, storing hygroscopic chemicals, or preventing atmospheric contamination. Desiccators with knobs are indispensable in laboratory, pharmaceutical, and industrial settings for maintaining low-humidity conditions during experiments or storage.

Filter Pump

Filter Pump is a laboratory device designed to create a vacuum using water or air flow to assist in filtration processes. Typically made from corrosion-resistant metal, plastic, or a combination of both, it operates by utilizing the Venturi effect to generate negative pressure. This suction power is ideal for accelerating vacuum filtration by drawing liquid through filter media quickly and efficiently. Filter pumps are commonly used in chemical, biological, environmental, and industrial laboratories where rapid and effective liquid-solid separation is required. They are a cost-effective and reliable alternative to mechanical vacuum pumps in many low-to-moderate vacuum applications.

Paint Gauge

A Paint Gauge is a precise measuring instrument used in laboratories and quality control environments to measure the thickness of paint coatings and other surface finishes. It allows technicians and researchers to assess the uniformity and adequacy of paint layers on various substrates, ensuring compliance with industry standards and specifications. Paint gauges can be mechanical or digital, often employing magnetic, ultrasonic, or mechanical principles to provide accurate, non-destructive thickness measurements. They are essential tools in the manufacturing, automotive, aerospace, and construction industries for maintaining coating quality and durability.

PENCIL JOCKEY

A Pencil Jockey is a small laboratory tool designed to securely hold and manipulate pencils or fine writing instruments during detailed drawing, drafting, or note-taking tasks. Commonly used in scientific laboratories, drafting rooms, and educational settings, it ensures precision and comfort during use. Typically made from lightweight, durable

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders