Marble Chips Extra Pure

$ 17.10 Original price was: $ 17.10.$ 16.98Current price is: $ 16.98.

Bare Enamelled Copper Wire

$ 12.50 Original price was: $ 12.50.$ 12.45Current price is: $ 12.45.

Whatsapp Order

Bare Enamelled Copper Wire is a high-quality electrical conductor coated with a thin layer of insulating enamel. It is widely used in electrical and electronic applications where insulation and durability are required without adding bulk. The enamel coating provides excellent resistance to heat, abrasion, and chemicals, making it suitable for winding coils, transformers, motors, and inductors. The bare enamelled copper wire ensures efficient conductivity combined with insulation properties, ideal for both laboratory research and industrial manufacturing processes.

Description

Table of Contents

Toggle

Bare Enamelled Copper Wire

Primary Uses

- Laboratory Applications

- Used for making electromagnetic coils and prototypes in electrical experiments.

- Essential in research involving electric motors, transformers, and inductors.

- Utilized in testing insulation and conductivity properties.

- Applied in custom winding and circuit design in R&D laboratories.

Secondary Uses

- Industrial Applications

- Used extensively in the manufacturing of motors, transformers, inductors, and solenoids.

- Integral component in electrical appliances and machinery wiring.

- Employed in production lines for coil winding and electromagnet assembly.

- Utilized in repair and maintenance of electrical equipment.

KEY PRODUCT FEATURES

1.Basic Identification Attributes

- Material: Copper with enamel insulation

- Wire Type: Bare enamelled (magnet) wire

- Insulation: Thin enamel coating providing electrical insulation

2.Physical & Chemical Properties

- Conductivity: Excellent electrical conductivity due to copper core

- Thermal Resistance: Withstands elevated temperatures depending on enamel type

- Diameter: Available in various gauges for different applications

- Flexibility: Good mechanical flexibility for winding and shaping

3.Safety & Hazard Attributes

- Electrical Risks: Risk of electric shock if improperly handled; ensure insulation integrity

- Toxicity: Non-toxic, though enamel coating may emit fumes if overheated

- Allergens: None reported

4.Storage & Handling Attributes

- Storage Conditions: Store in dry, cool environment to prevent oxidation

- Handling Precautions: Avoid sharp bends or abrasion that could damage enamel coating

5.Regulatory & Compliance Attributes

- Complies with electrical standards for insulation and conductivity

- Manufactured to industrial quality standards for electrical wiring

6.Environmental & Health Impact

- Copper is recyclable; enamel coating disposal should follow environmental regulations

- Minimal environmental footprint during normal use

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- Use insulated gloves when handling live wires

- Avoid overheating to prevent enamel degradation

First Aid Measures

- Skin Contact: Wash if irritation occurs from dust or fumes

- Inhalation: Move to fresh air if exposed to fumes from overheating enamel

- Eye Contact: Rinse with water if contact with dust or fumes occurs

- Ingestion: Seek medical attention if enamel particles ingested

Firefighting Measures

- Fire Hazard: Copper wire itself is non-flammable; enamel coating may burn under extreme heat

- Extinguishing Media: Use dry chemical, CO2, or foam for enamel fire

- Special Precautions: Avoid inhaling fumes from burning enamel

Related products

Banana Plug

The Banana Plug is a single-wire electrical connector used to join wires to equipment in testing, measuring, and laboratory applications. It features a cylindrical metal pin with a spring mechanism to ensure a secure and reliable connection. The plug is widely used for quick and easy connections in electronic testing devices, audio systems, and laboratory instruments. Made from high-conductivity metals such as brass or copper and often gold- or nickel-plated for corrosion resistance, the Banana Plug provides consistent electrical conductivity and durability.

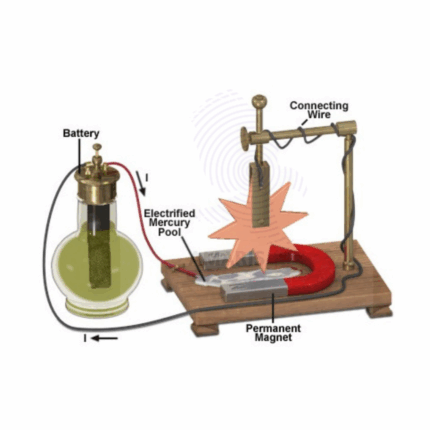

Barlows Wheel Apparatus

Barlows Wheel Apparatus is a classic physics demonstration device used to illustrate electromagnetic effects, specifically the principles of electric motors and the interaction between magnetic fields and electric current. It consists of a rotating wheel in contact with an electric circuit and a magnetic field, demonstrating motion generated by electromagnetic forces. The apparatus is widely used in educational laboratories to teach fundamental concepts of electromagnetism and motor action, as well as in industrial training for understanding motor components and operation.

Bell in Vacuum

Bell in Vacuum is a crucial component used in vacuum systems to create an airtight seal and protect sensitive equipment from atmospheric contamination. Typically made of durable, corrosion-resistant materials, it forms part of vacuum chambers or devices requiring controlled environments. The bell ensures the maintenance of vacuum integrity by preventing air ingress, making it essential for experiments and industrial processes that depend on low-pressure or vacuum conditions.

Boyle’s Law Apparatus

Boyle’s Law Apparatus is a precision laboratory instrument designed to demonstrate and verify Boyle’s Law, which states that the pressure of a given mass of gas is inversely proportional to its volume at constant temperature. The apparatus typically consists of a sealed cylinder with a movable piston or syringe, pressure gauge, and volume scale, allowing students and researchers to observe and measure the relationship between pressure and volume in gases. It is widely used in educational and research laboratories to teach fundamental gas laws and perform experimental validation of theoretical principles.

Chromatogram Paper

Chromatogram Paper is a specialized high-quality absorbent paper used primarily in chromatography techniques for the separation and analysis of chemical substances. Manufactured to have consistent texture and porosity, it facilitates effective migration of solvents and analytes, allowing clear and reproducible chromatographic patterns. Widely utilized in laboratories for qualitative and quantitative chemical analysis, Chromatogram Paper is essential for research, quality control, and educational purposes.

Crookes radiometer

The Crookes Radiometer, also known as a light mill, is a scientific apparatus consisting of a glass bulb containing a partial vacuum and a rotor with vanes coated black on one side and white or silver on the other. When exposed to light or radiant energy, the vanes rotate due to differential thermal transpiration, demonstrating principles of gas kinetics and energy conversion. It is commonly used for educational demonstrations of light pressure and thermodynamics.

Crucible Tongs

Crucible Tongs are specialized metal tools designed for safely handling hot crucibles, evaporating dishes, and other laboratory apparatus exposed to high temperatures. Made from durable, heat-resistant metals such as stainless steel or nickel-plated steel, these tongs provide a firm grip, ensuring the safe transfer of heated items during laboratory procedures, including heating, melting, and chemical reactions.

Dip Needle Complete

Dip Needle Complete is a fully assembled and calibrated magnetic dip measurement instrument used for precise determination of the Earth’s magnetic inclination angle. This complete apparatus includes a magnetized dip needle mounted on a low-friction pivot within a protective housing, accompanied by a graduated circular scale for accurate angular readings. The instrument is designed for use in geophysical surveys, educational labs, and research institutions to study Earth’s magnetic field behavior. The complete setup ensures reliable, repeatable measurements with enhanced durability and ease of use, suitable for both field and laboratory environments.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders