Bitumen Primer Extra Pure

Bitumen Primer Extra Pure is a high-purity, low-viscosity liquid used in laboratory and industrial research involving adhesion studies, waterproofing technologies, and material compatibility testing. It consists primarily of refined bitumen dissolved in a suitable solvent, allowing it to penetrate and seal porous substrates like concrete, masonry, or metal. In laboratory contexts, it is used to study the behavior of protective coatings, surface treatments, and corrosion resistance. The extra pure grade ensures minimal impurities and uniform consistency, supporting accurate and reproducible test results. Bitumen Primer should be stored in a tightly closed container in a well-ventilated area, away from heat sources, sparks, and open flames

USES

Primary Uses

- Material Adhesion Testing

- Used in laboratory tests of bonding strength between bituminous layers and various substrates (e.g., concrete, metal, glass) for civil or materials engineering studies.

- Formulation Studies

- Serves as a base compound in lab-scale modification experiments (e.g., adding polymers, resins, or solvents to study effects on drying time, viscosity, and adhesion).

- Analytical Characterization

- Investigated using techniques like GC-MS, FTIR, or TGA to analyze composition, volatility, and thermal behavior of bituminous coatings.

- Waterproofing Material Simulation

- Used in small-scale simulations of waterproofing systems, helping researchers study moisture barriers and coating performance under controlled conditions.

Secondary Uses

- Educational Demonstrations

- Used in civil engineering or construction chemistry labs to demonstrate priming methods, penetration properties, and setting behavior.

- Corrosion Protection Studies

- Tested as a corrosion-resistant primer in metal exposure experiments, particularly under salt spray or humid environments.

- Comparative Coating Performance Research

- Used alongside synthetic and eco-friendly alternatives in studies comparing environmental impact and durability.

- Binder Compatibility Studies

- Investigated for interaction with asphalt, aggregates, and additives in binder blend compatibility testing.

KEY ATTRIBUTES

1. Basic Identification Attributes

- Product Name: Bitumen Primer Extra Pure

- General Description: A high-purity, solvent-based bituminous primer designed for adhesion promotion in waterproofing tests, material compatibility studies, and sample preparations in lab settings.

- CAS Number: Mixture (primary components include Bitumen [CAS: 8052-42-4] + hydrocarbon solvents)

- HS Code: 2715.00.00 (Bituminous mixtures)

- Grade: Extra Pure (suitable for controlled lab applications)

- Composition:

- Refined bitumen (asphalt)

- Solvents like mineral spirits, naphtha, or toluene

2. Physical & Chemical Properties

- Physical State: Liquid

- Appearance: Dark brown to black viscous liquid

- Odor: Strong petroleum-like odor

- Boiling Point: 120–200 °C (depending on solvent blend)

- Flash Point: ~35–45 °C (flammable)

- Density: ~0.90–1.05 g/cm³

- Solubility:

- Water: Insoluble

- Organic solvents: Soluble in aliphatic and aromatic hydrocarbons

- Viscosity: Medium to high

- Vapor Pressure: Moderate (due to solvent content)

3. Safety & Hazard Attributes

- GHS Classification:

- Flammable Liquid (Category 3)

- Skin Irritant (Category 2)

- Specific Target Organ Toxicity – Single Exposure (Category 3)

- GHS Pictograms:

⚠️ 🔥 - NFPA Ratings:

- Health: 2

- Flammability: 3

- Reactivity: 0

- Primary Hazards in Lab:

- Flammable vapors

- Skin/eye irritation

- Inhalation hazard from fumes

- Personal Protective Equipment (PPE):

- Nitrile gloves, safety goggles, lab coat

- Use in fume hood when heated or sprayed

4. Storage & Handling Attributes

- Storage Conditions:

- Store in flammable chemical cabinet

- Keep container tightly closed

- Protect from heat, sparks, open flame

- Incompatible Materials:

- Oxidizing agents, strong acids, alkalis

- Container Type:

- Metal or solvent-resistant plastic with sealed lid

- Shelf Life:

- Up to 2 years under proper storage

- Handling Notes (Lab):

- Mix thoroughly before use

- Avoid skin contact and fume inhalation

5. Regulatory & Compliance Attributes

- Regulatory Status:

- Regulated for flammability and VOC content

- Not classified as carcinogenic in pure lab-grade form, but prolonged exposure may carry risk (depending on bitumen refinement)

- Transportation Restrictions:

- UN 1999, Class 3 (Flammable liquid, n.o.s.)

- Must follow DG transport guidelines

- Disposal Method:

- Hazardous waste – collect and dispose of per local environmental regulations

6. Environmental & Health Impact

- Ecotoxicity: Harmful to aquatic life (due to hydrocarbon solvents)

- Persistence: Bitumen components are persistent in the environment

- Bioaccumulation: Low to moderate depending on solvent type

Carcinogenicity: Potential concern only if polycyclic aromatic hydrocarbons (PAHs) are present — not typical in extra pure lab grade

SAFETY PRECAUTIONS

- Personal Protective Equipment (PPE):

- Wear chemical-resistant gloves, lab coat, and safety goggles.

- Use respiratory protection if adequate ventilation is not ensured.

- Handling:

- Handle in a well-ventilated fume hood due to the presence of volatile organic solvents.

- Avoid inhalation, skin contact, and eye exposure.

- Keep away from sparks, flames, and heat sources – product is highly flammable.

- Storage:

- Store in a cool, well-ventilated area, away from direct sunlight and ignition sources.

- Keep the container tightly closed when not in use.

- Ground/bond container and receiving equipment to prevent static discharge.

- Hygiene Measures:

- Wash thoroughly after handling.

- Do not eat, drink, or smoke in areas where the product is used or stored.

FIRST AID MEASURES

- Inhalation:

- Remove the victim to fresh air.

- If breathing is difficult, administer oxygen.

- Seek immediate medical attention.

- Skin Contact:

- Wash with soap and water.

- Remove contaminated clothing.

- Seek medical attention for irritation or burns.

- Eye Contact:

- Flush immediately with plenty of water for at least 15 minutes.

- Hold eyelids open during flushing.

- Seek medical help promptly.

- Ingestion:

- Do not induce vomiting (may cause aspiration into lungs).

- Rinse your mouth if conscious.

- Get immediate medical assistance.

FIRE FIGHTING MEASURES

- Extinguishing Media:

- Use foam, dry chemical powder, carbon dioxide (CO₂).

- Do not use water jets (can spread the fire).

- Fire Hazards:

- Highly flammable — vapors may form explosive mixtures with air.

- Combustion releases toxic fumes: carbon monoxide, carbon dioxide, and smoke.

- Protective Equipment for Firefighters:

- Wear self-contained breathing apparatus (SCBA).

- Use full protective firefighting gear.

- Explosion Risk:

- Vapors can travel along surfaces to a distant ignition source.

- Ensure proper grounding during transfer operations.

Acidulants

Acidulants Antioxidants

Antioxidants Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food)

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

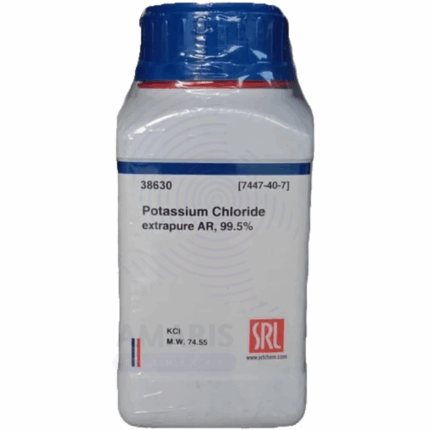

Analytical Reagents

Analytical Reagents Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders