Filler WTD

Whatsapp Order

Filler WTD is a versatile, finely processed powdered filler primarily used in a wide range of industrial applications including paints, coatings, plastics, adhesives, sealants, rubber compounds, and construction materials. It is engineered to improve product performance by enhancing mechanical properties, increasing volume, reducing cost, and improving processing characteristics. Filler WTD typically exhibits excellent dispersibility, consistent particle size distribution, and good compatibility with various resin systems and binders. Its primary role is to act as an inert extender or reinforcing agent, providing bulk and stability while maintaining or enhancing the physical and chemical properties of the final formulation.

Description

Table of Contents

Toggle

Filler WTD

Primary Uses

- Paints and Coatings

- Serves as an extender pigment to increase volume and reduce formulation costs without compromising coating quality.

- Enhances opacity, brightness, and surface smoothness of paints and varnishes.

- Improves mechanical properties such as scratch resistance, durability, and weathering performance.

- Aids in controlling viscosity and rheology for better application and flow.

- Plastics and Polymers

- Used as a reinforcing filler in thermoplastics and thermosets to improve stiffness, dimensional stability, and impact resistance.

- Helps reduce shrinkage and warpage during molding processes.

- Contributes to improved processing efficiency by modifying melt flow and extrusion characteristics.

- Acts as a cost-effective volume extender to reduce raw material expenses.

- Adhesives and Sealants

- Enhances the mechanical strength and durability of adhesive bonds and sealant compounds.

- Controls shrinkage and curing characteristics.

- Improves workability and consistency of formulations.

- Rubber Compounds

- Used as a reinforcing or processing filler in natural and synthetic rubber products to improve tensile strength, abrasion resistance, and elasticity.

- Assists in controlling hardness and resilience of rubber goods.

- Construction Materials

- Incorporated into cement, mortar, plaster, and putty formulations to improve bulk, reduce cracking, and enhance workability.

- Improves texture and finish quality of architectural coatings and plasters.

Secondary Uses

- Paper Industry

- Utilized as a filler to improve paper opacity, brightness, and printability.

- Enhances surface smoothness and ink receptivity.

- Ceramics and Glass

- Acts as a functional filler in ceramic bodies to improve firing behavior and mechanical properties.

- Used in glass formulations to modify melting points and optical properties.

- Cosmetics

- Occasionally employed in personal care formulations (e.g., powders) as a texturizing and bulking agent, though this is less common depending on composition.

KEY PRODUCT FEATURES

1. Basic Identification Attributes

- Chemical Name: Variable depending on composition (commonly calcium carbonate, talc, silica, or other mineral fillers)

- Common/Trade Name: Filler WTD

- CAS Number: Depends on primary mineral content (e.g., calcium carbonate CAS 471-34-1)

- HS Code: Varies depending on material but generally under 2508, 2529, or related chapters

- Molecular Formula: Variable depending on specific filler chemistry

2. Physical & Chemical Properties

- Physical State: Fine powder

- Color: Off-white to white, depending on formulation

- Odor: Odorless

- Particle Size: Typically micron-sized, uniform distribution for optimal dispersibility

- Density: Varies (usually 2.5–2.8 g/cm³ for mineral fillers)

- Solubility: Insoluble in water and organic solvents

- pH: Neutral to slightly alkaline depending on composition

- Stability: Chemically inert and stable under normal processing and storage conditions

3. Safety & Hazard Attributes

- Hazard Class (GHS): Generally classified as non-hazardous inert material; dust may cause respiratory irritation

- Toxicity: Low toxicity; prolonged inhalation of dust may cause respiratory discomfort

- Exposure Limits: Follow local occupational exposure limits for nuisance dust (typically OSHA PEL = 15 mg/m³ total dust, 5 mg/m³ respirable dust)

4. Storage & Handling Attributes

- Storage Conditions: Store in dry, cool, and well-ventilated areas; avoid moisture to prevent caking

- Container Type: Bags or bulk containers designed to minimize moisture ingress

- Shelf Life: Indefinite if stored properly in sealed, dry conditions

- Handling Precautions: Use dust control measures; wear PPE during handling to avoid dust inhalation

5. Regulatory & Compliance Attributes

- Complies with relevant industry standards for fillers in paints, plastics, and construction materials

- Registered and approved for use in applicable industries according to regional regulatory frameworks

6. Environmental & Health Impact

- Biodegradability: Inert mineral fillers do not biodegrade but are environmentally stable

- Ecotoxicity: Generally low environmental impact; avoid uncontrolled release into waterways

- Bioaccumulation: Not applicable

- Carcinogenicity/Mutagenicity: Not carcinogenic; inert mineral nature

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- PPE Required: Dust mask or respirator, safety goggles, gloves

- Handling Guidelines: Minimize dust generation; use local exhaust ventilation where possible

- Storage Measures: Keep containers sealed and dry

- Hygiene Practices: Wash hands after handling; avoid eating/drinking in handling areas

First Aid Measures

- Inhalation: Move to fresh air; seek medical advice if respiratory irritation occurs

- Skin Contact: Wash with soap and water; seek medical attention if irritation develops

- Eye Contact: Rinse thoroughly with water for at least 15 minutes; consult a physician if irritation persists

- Ingestion: Rinse mouth; seek medical advice if large quantities swallowed

Firefighting Measures

- Fire Hazards: Non-flammable

- Extinguishing Media: Use appropriate media for surrounding fire

- Special Precautions: None specific to Filler WTD; avoid dust cloud ignition

Related products

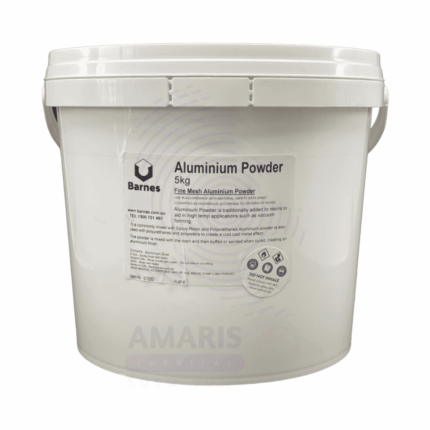

Aluminum Fine Powder

$ 0.20

Aluminum fine powder consists of finely divided aluminum particles, typically metallic and silvery-white in appearance. It is produced by atomization or grinding of bulk aluminum and is valued for its high surface area, excellent conductivity, and lightweight metallic properties. Aluminum fine powder is extensively used in various industrial applications including metallurgy, pyrotechnics, coatings, additive manufacturing, and as a pigment. Due to its reactivity, it requires careful handling and storage. Its fine particulate nature makes it particularly useful where rapid oxidation or reaction is desired, such as in explosives or energetic materials. It is also employed in the manufacturing of paints, inks, and cosmetics to impart metallic luster.

Binder

A binder is a broad category of substances—organic or inorganic—used to hold different materials together in a cohesive mass. Common binders include natural polymers (starch, cellulose derivatives, proteins), synthetic resins (PVA, acrylics, phenolics), and inorganic binders (clays, cement, lime). They are essential in industries such as pharmaceuticals, construction, coatings, ceramics, adhesives, and printing, where they provide structural integrity, adhesion, and controlled release properties.

Master Fibre

Master Fibre is a high-quality synthetic fiber additive designed to reinforce concrete and mortar mixtures. It improves structural integrity by enhancing tensile strength, reducing cracking, and increasing durability. The fibers disperse uniformly within the mix, providing better load distribution and impact resistance in industrial, commercial, and residential construction applications. Master Fibre enhances performance without compromising workability, making it ideal for use in concrete slabs, pavements, beams, and repair mortars.

Polywhite B

Polywhite B Chinaclay, commonly known as Chinaclay, is a naturally occurring, fine white clay mineral primarily composed of kaolinite. It is highly valued for its purity, whiteness, and fine particle size, making it suitable for a variety of industrial applications. Polywhite B improves texture, opacity, and durability in products and is widely used in ceramics, paper, paints, and rubber industries.

Silicon Dioxide

Silicon Dioxide (SiO₂), commonly known as silica, is a naturally occurring inorganic compound found abundantly in the Earth’s crust. In its refined, powdered form, it is used as an anti-caking agent, filler, absorbent, and thickener across a wide range of industries. It is odorless, tasteless, chemically inert, and stable under normal conditions. Packaged in 10kg units, silicon dioxide is highly versatile and widely accepted for use in food, pharmaceutical, cosmetic, and industrial applications.

Sodium Alumina Silicate

Sodium Alumina Silicate is an inorganic compound consisting of sodium, aluminum, and silicon oxides. It is typically found as a white, amorphous powder with excellent adsorption and ion-exchange properties. Commonly used as a detergent builder, water softener, and desiccant, sodium alumina silicate improves cleaning efficiency, controls water hardness, and aids moisture absorption. Its thermal stability and chemical inertness make it valuable across detergent manufacturing, water treatment, and various industrial processes.

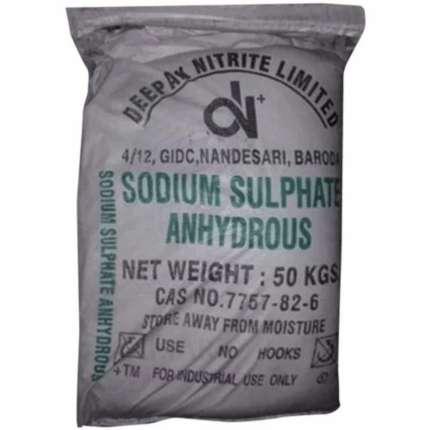

Sodium Sulphate Anhydrous

Sodium Sulphate Anhydrous (Na₂SO₄) is a white crystalline powder, odorless and highly soluble in water. Unlike the decahydrate form (Glauber's salt), this anhydrous grade contains minimal water content, making it ideal for industrial applications requiring low moisture levels. Supplied in 25kg packaging, it is widely used as a filler, drying agent, and raw material in detergents, glass manufacturing, pulp and paper, and chemical synthesis. Its excellent stability, non-hygroscopic nature, and cost-effectiveness make it an essential bulk chemical.

Whiting

Whiting is a finely ground, white, chalky substance primarily composed of calcium carbonate (CaCO₃). It is widely used as a pigment, filler, and extender in various industrial and commercial applications. Whiting provides opacity, brightness, and smoothness to products, enhancing their appearance and physical properties. Its natural abundance and versatility make it an economical additive in multiple manufacturing processes.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders