Back to products

Galvanometer Zero Center

$ 17.99 Original price was: $ 17.99.$ 17.83Current price is: $ 17.83.

G Clamp

$ 13.60 Original price was: $ 13.60.$ 13.45Current price is: $ 13.45.

Whatsapp Order

G Clamp is a versatile clamping tool widely used in woodworking, metalworking, and laboratory applications to hold objects securely in place. Shaped like the letter “G,” it features a screw mechanism that allows adjustable pressure to firmly grip materials during assembly, welding, gluing, or testing. Made from durable cast iron or steel, G Clamps offer strong holding power and reliable stability, making them essential for precision work and safety in various industrial, construction, and laboratory settings.

Description

Table of Contents

Toggle

G Clamp

Primary Uses

- Workshop and Fabrication

- Holding wood, metal, or plastic pieces firmly during cutting, drilling, or shaping.

- Securing materials in place while gluing or welding.

- Used in jig and fixture setups for precise assembly tasks.

- Provides stability during sanding and finishing operations.

- Laboratory Applications

- Clamping glassware, apparatus, or experimental setups securely on stands.

- Holding equipment during chemical or physical experiments requiring stable positioning.

Secondary Uses

- Construction and Industrial Applications

- Temporary fixation of components during installation or repairs.

- Supporting parts in place during painting or surface treatments.

- Useful in metal fabrication shops for welding and brazing tasks requiring firm grip.

KEY PRODUCT FEATURES

1.Basic Identification Attributes

- Material: Cast iron or steel construction

- Mechanism: Screw-type adjustable pressure clamp

- Size: Available in various jaw openings and throat depths

2.Physical & Chemical Properties

- High mechanical strength and durability

- Corrosion resistant coating or paint finish for longevity

- Heavy-duty design for firm gripping without slipping

3.Safety & Hazard Attributes

- Potential pinch points requiring careful handling

- Use caution to avoid over-tightening, which may damage workpieces or clamp

4.Storage & Handling Attributes

- Store in dry environments to prevent rust

- Keep threaded screw clean and lubricated for smooth operation

- Handle with care to avoid injury from sudden clamp release

5.Regulatory & Compliance Attributes

- Manufactured to meet industrial tool safety standards

- Suitable for professional and laboratory-grade applications

6.Environmental & Health Impact

- Made from recyclable metal materials

- Durable design reduces frequent replacement and waste

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- Wear gloves to protect hands during tightening and release

- Avoid sudden release to prevent injury

- Ensure proper use to prevent damage to materials or clamp

First Aid Measures

- In case of pinching injuries, clean wound and seek medical attention if necessary

- For cuts or abrasions, disinfect and apply appropriate treatment

Firefighting Measures

- Non-flammable tool, but keep away from heat sources

- No special extinguishing measures required

Related products

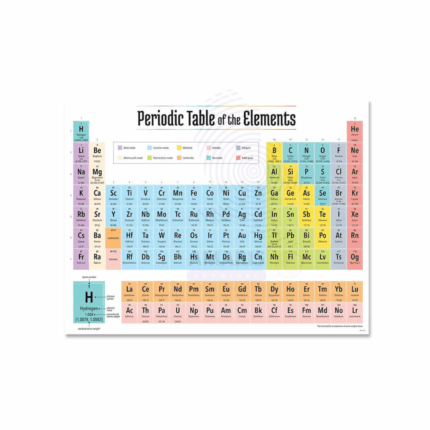

Charts Biology and Chemistry

Product Description

Charts Biology and Chemistry are educational visual aids designed to illustrate key concepts, processes, and structures in biology and chemistry. These charts typically feature detailed diagrams and labeled components covering topics such as cellular biology, chemical elements, molecular structures, and laboratory safety. They enhance learning and teaching effectiveness in classrooms and laboratories.

Complete burette stand

The Complete Burette Stand is a sturdy laboratory apparatus designed to securely hold burettes during titration and other volumetric experiments. Typically made of metal with a stable base, it features adjustable clamps and rods to accommodate different sizes of burettes and provide stability during precise liquid dispensing. Its durable construction ensures safety and accuracy in laboratory workflows.

Glass Tubing Cutter File

Glass Tubing Cutter File is a specialized tool designed for scoring and preparing glass tubes before breaking them cleanly. It typically features a hardened steel or diamond-coated cutting surface combined with a file mechanism to smooth and shape the scored area, ensuring precise and controlled glass cutting. This tool is essential for laboratory technicians, glassworkers, and craftsmen who work with glass tubing, enabling safe and accurate customization of glass lengths and shapes.

Italtext Premium Heavy Duty

Italtext Premium Heavy Duty is a robust, high-quality laboratory apparatus engineered for rigorous and extended use in demanding lab environments. Designed with durability and stability in mind, this heavy-duty apparatus supports a wide range of laboratory operations, from analytical procedures to sample processing. Its premium construction ensures consistent performance under mechanical stress, high-frequency use, and exposure to chemicals. Ideal for laboratory professionals requiring reliable and long-lasting equipment, Italtext Premium offers an optimal balance of strength, precision, and ergonomic handling in both research and industrial settings.

PENCIL JOCKEY

A Pencil Jockey is a small laboratory tool designed to securely hold and manipulate pencils or fine writing instruments during detailed drawing, drafting, or note-taking tasks. Commonly used in scientific laboratories, drafting rooms, and educational settings, it ensures precision and comfort during use. Typically made from lightweight, durable

PLASTIC DISSECTING TRAY WITHOUT WAX

The Plastic Dissecting Tray without Wax is a laboratory instrument used to hold specimens during dissection procedures in biology, zoology, anatomy, and educational labs. Unlike traditional dissecting trays that include a wax layer for pinning specimens, this tray offers a reusable, wax-free surface, typically designed to accommodate separate pinning pads or mats (e.g., rubber or foam inserts). It is made from high-grade, chemical-resistant plastic such as polypropylene or ABS, offering a lightweight, durable, and easy-to-clean platform. The tray typically features raised sides to contain fluids and provide a controlled

PLASTIC TEST TUBE STAND 6HOLE

The Plastic Test Tube Stand 6Hole is a laboratory support accessory designed to securely hold test tubes in an upright position during experimental procedures, storage, or drying. This version features six equally spaced holes, each capable of accommodating standard-size test tubes. Constructed from chemical-resistant, durable plastic such as polypropylene or ABS, the stand is lightweight, stable, and easy to clean. Often used in educational, analytical, and clinical laboratories, it provides a convenient and organized way to manage test tubes during chemical reactions, sample handling, or heating processes. The design may also include drying pegs or smaller side holes for inverted tube drying.

Terminals

Product Description

Terminals are essential electrical connectors used in laboratory and industrial setups to create secure, reliable connections between wires, cables, and electrical equipment. Typically made from conductive metals such as copper or brass and often coated with corrosion-resistant materials, terminals facilitate the transfer of electrical signals or power with minimal resistance. They come in various types including ring, spade, fork, and blade terminals to suit diverse wiring requirements. Terminals are widely used in electrical circuits, instrumentation, and control panels within laboratories to ensure safe and efficient electrical connections.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders