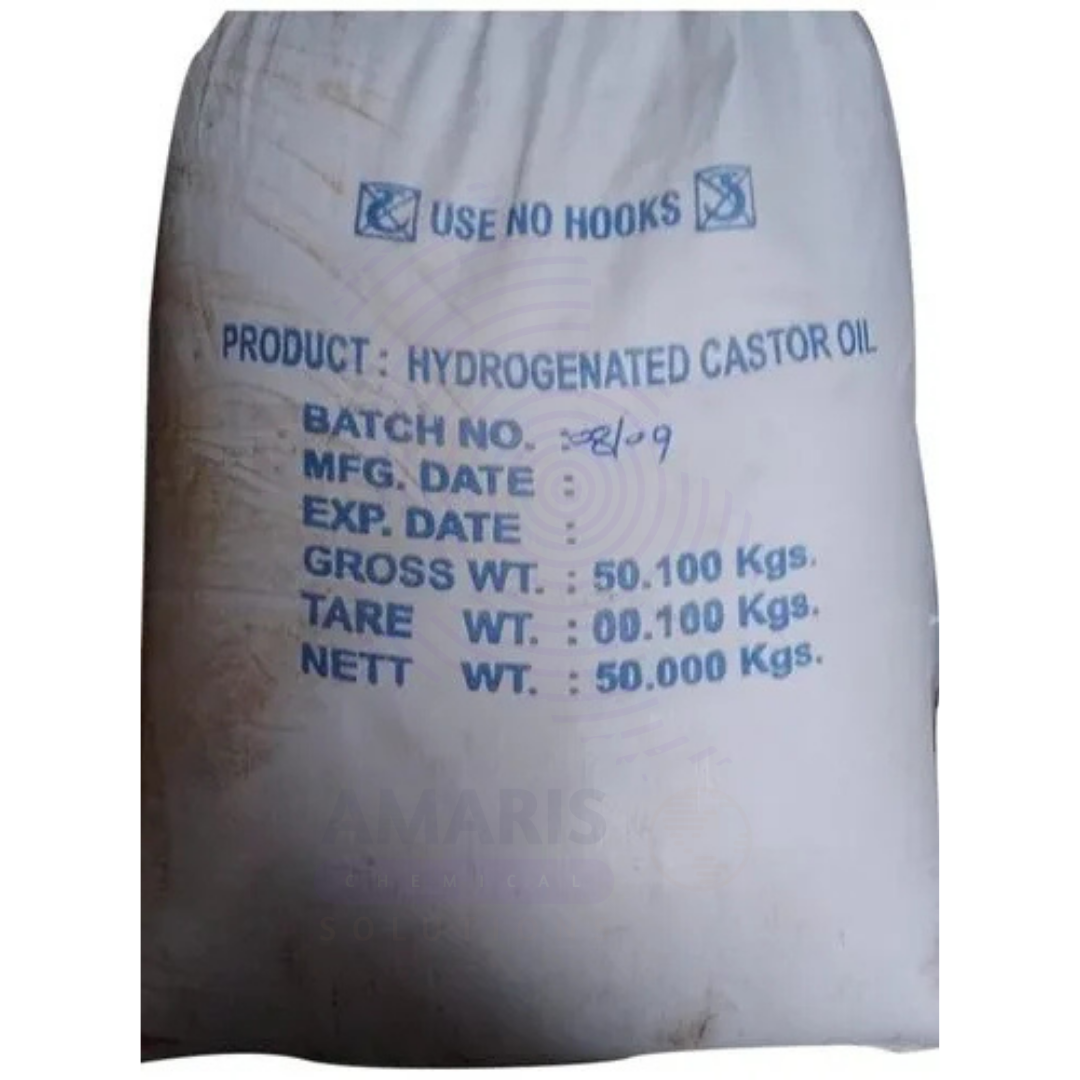

Hydrogenated Castor Oil

$ 12.60 Original price was: $ 12.60.$ 12.53Current price is: $ 12.53.

Hydrogenated Castor Oil, also known as castor wax, is a hard, brittle, and high-melting-point wax derived by the hydrogenation of pure castor oil. This white to off-white, odorless substance is non-toxic and insoluble in water but dispersible in surfactant systems. Its primary component is hydrogenated ricinoleic acid triglyceride, and it is prized for its excellent lubricating, emulsifying, thickening, and consistency-enhancing properties.

Due to its stability, non-reactivity, and film-forming capability, Hydrogenated Castor Oil is widely used in cosmetics, personal care, pharmaceuticals, industrial lubricants, coatings, plastics, and more. It improves product texture, enhances emulsion stability, and provides moisture retention in skincare applications.

Hydrogenated Castor Oil

Primary Uses

- Cosmetics and Personal Care

- Used as a thickener and consistency agent in creams, lotions, and balms.

- Acts as an emollient and moisturizer in lipsticks, lip balms, and solid perfumes.

- Enhances texture in deodorants, stick foundations, and makeup products.

- Forms stable emulsions in water-in-oil or oil-in-water formulations.

- Applied in soaps and cleansing bars to improve hardness and lather conditioning.

- Pharmaceuticals

- Used as a pharmaceutical excipient in ointments and medicated creams.

- Included in controlled-release drug delivery systems due to its waxy nature.

- Serves as a base in dermatological applications and wound-protective salves.

- Industrial Applications

- Used in coatings and inks for its excellent film-forming and anti-corrosion properties.

- Acts as a lubricant and dispersing agent in plastics and rubber formulations.

- Used in the production of greases, polishes, and surface coatings for metals and leathers.

- Hair Care Products

- Added to conditioners and styling products for shine and film-forming properties.

- Enhances hold and moisture retention in pomades and styling waxes.

Secondary Uses

- Textile and Leather Processing

- Used in formulations to provide smooth finish and conditioning to leathers.

- Acts as a lubricant and antistatic agent in textile softeners.

- Pet Care Products

- Included in paw balms and grooming waxes for safe application on pets.

- Craft and DIY Formulations

- Used in handmade lip balms, solid perfumes, and natural stick deodorants.

- Ideal for creating balmy, stable oil-based salves and wax-based aromatherapy products.

| PACK SIZE | 5kg |

|---|

1. Basic Identification Attributes

- Botanical Source: Ricinus communis

- Common/Trade Name: Hydrogenated Castor Oil / Castor Wax

- INCI Name: Hydrogenated Castor Oil

- CAS Number: 8001-78-3

- HS Code: 1515.30

- Synonyms: Castor Wax, Fully Hydrogenated Castor Oil, Ricinus Wax

2. Physical & Chemical Properties

- Physical State: Solid wax

- Color & Odor: White to off-white; odorless or faintly fatty

- Melting Point: 80–90°C

- Solubility: Insoluble in water; soluble in hot oils and solvents

- Acid Value: ≤ 4 mg KOH/g

- Saponification Value: 175–185 mg KOH/g

- Iodine Value: ≤ 4

3. Safety & Hazard Attributes

- GHS Classification: Not classified as hazardous

- Toxicity: Non-toxic and safe for personal care use

- Exposure Limits: None established for topical use

- Allergen Information: Derived from castor oil; patch testing advised for sensitive users

4. Storage & Handling Attributes

- Storage Conditions: Store in a dry, cool place away from direct sunlight

- Container Type: Fiber drums, lined bags, or HDPE containers

- Shelf Life: Up to 24–36 months under ideal storage conditions

- Handling Precautions: Melt with controlled heat; avoid contamination with moisture

5. Regulatory & Compliance Attributes

- Compliant with FDA and EU cosmetic ingredient regulations

- Approved for pharmaceutical excipient use (USP/NF compliant)

- GMP-grade versions available for regulated applications

- Suitable for use in vegan and cruelty-free formulations

6. Environmental & Health Impact

- Biodegradability: Biodegradable under environmental conditions

- Ecotoxicity: Low environmental hazard profile

- Bioaccumulation: Not expected to bioaccumulate

Safety Handling Precautions

- PPE Required: Protective gloves and safety glasses recommended during handling

- Handling Guidelines: Avoid inhalation of dust during crushing or melting

First Aid Measures

- Inhalation: Not hazardous in solid form; avoid inhaling dust

- Skin Contact: Safe; wash with soap and water if irritation develops

- Eye Contact: Rinse with water if particles contact the eyes

- Ingestion: Non-toxic in small quantities; seek help if large amounts are ingested

Firefighting Measures

- Fire Hazards: Combustible in molten form

- Extinguishing Media: Dry chemical, foam, or carbon dioxide

- Special Precautions: Use full protective gear and breathing apparatus

- Hazardous Combustion Products: Carbon monoxide, carbon dioxide

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders