Hydrogen Peroxide Food Grade

$ 2.00 Original price was: $ 2.00.$ 1.44Current price is: $ 1.44.

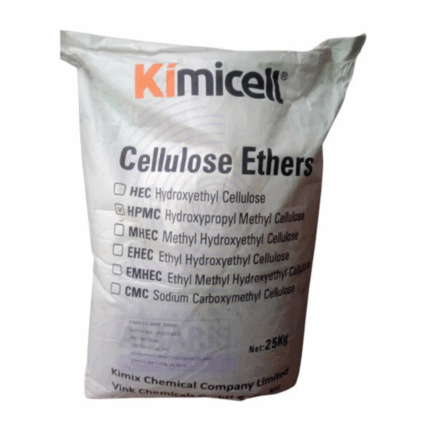

Hydroxypropyl Methylcellulose HPMC

Whatsapp Order

Hydroxypropyl Methylcellulose HPMC, also known as hypromellose, is a semi-synthetic, non-ionic cellulose ether derived by chemically modifying cellulose through methylation and hydroxypropylation. It is a white to off-white, odorless, tasteless powder that dissolves in cold water to form clear, viscous solutions. HPMC is renowned for its thickening, film-forming, emulsifying, and controlled-release properties. It is widely used in pharmaceuticals, food, cosmetics, construction, and industrial applications due to its safety profile, versatility, and compatibility with various ingredients.

Description

Table of Contents

Toggle

Hydroxypropyl Methylcellulose HPMC

Primary Uses

- Pharmaceutical Industry

- Used as a binder, film former, and controlled-release agent in oral solid dosage forms such as tablets and capsules.

- Employed as a viscosity enhancer and suspending agent in ophthalmic solutions, gels, and topical formulations.

- Acts as a matrix polymer in sustained-release drug delivery systems, regulating drug dissolution and absorption.

- Serves as a protective colloid and stabilizer in various pharmaceutical suspensions and emulsions.

- Food Industry

- Utilized as a thickener, emulsifier, and stabilizer in bakery products, dairy alternatives, sauces, and dressings.

- Functions as a gluten substitute in gluten-free baking, improving texture and moisture retention.

- Acts as an anti-caking agent and film former in edible coatings and wraps.

- Cosmetics and Personal Care

- Incorporated as a thickening agent, stabilizer, and film former in creams, lotions, shampoos, and sunscreens.

- Enhances product texture, improves spreadability, and stabilizes emulsions.

- Provides moisturizing and protective effects in topical formulations.

- Construction Industry

- Used as a water retention agent and thickener in cement, mortar, and plaster formulations.

- Improves workability, adhesion, and surface smoothness of building materials.

- Industrial Applications

- Functions as a thickener, binder, and stabilizer in paints, coatings, adhesives, and printing inks.

- Employed in ceramics and paper manufacturing as a binder and rheology modifier.

Secondary Uses

- Oil & Gas Industry

- Applied as a viscosifier and stabilizer in drilling fluids and fracturing gels.

- Textile Industry

- Used as a sizing agent and thickener in textile printing and finishing processes.

- Biomedical Research

- Utilized in tissue engineering and as a component in hydrogel scaffolds due to its biocompatibility.

KEY ATTRIBUTES

- Basic Identification Attributes

- Chemical Name (IUPAC): Hydroxypropyl methylcellulose

- Common/Trade Name: HPMC, Hypromellose

- CAS Number: 9004-65-3

- HS Code: 3912.90.00

- Molecular Formula: Variable polymer (C12H20O10)n substituted with methyl and hydroxypropyl groups

- Synonyms: Hypromellose, Methocel, Methocel E series

- Physical & Chemical Properties

- Physical State: White to off-white powder

- Odor: Odorless

- Solubility: Soluble in cold water forming clear, viscous solutions; insoluble in organic solvents

- Viscosity Range: Adjustable from low to high depending on substitution and molecular weight

- pH Stability: Stable between pH 3 to 11

- Thermal Stability: Stable up to approximately 200–220 °C (degradation above this range)

- Safety & Hazard Attributes

- GHS Classification: Generally regarded as safe; non-toxic, non-irritating

- Toxicity: Low acute toxicity; non-sensitizing

- Exposure Limits: No occupational exposure limits established

- Storage & Handling Attributes

- Storage Conditions: Store in a cool, dry, well-ventilated area away from moisture and heat

- Container Type: Sealed polyethylene bags or drums

- Shelf Life: Typically 24 months under recommended conditions

- Handling Precautions: Avoid dust formation and inhalation; use dust masks if necessary

- Regulatory & Compliance Attributes

- Approved for use in pharmaceuticals (USP/NF), food (FDA GRAS), and cosmetics globally

- Listed in pharmacopoeias and cosmetic ingredient directories (INCI: Hydroxypropyl Methylcellulose)

- Environmental & Health Impact

- Biodegradability: Biodegradable under aerobic conditions

- Ecotoxicity: Low toxicity to aquatic life

- Bioaccumulation: Not expected to bioaccumulate

- Carcinogenicity/Mutagenicity: Not classified as carcinogenic or mutagenic

SAFETY HANDLING PRECAUTIONS

- Safety Handling Precautions

- PPE Required: Dust mask, gloves, and safety goggles when handling powder

- Handling Guidelines: Minimize dust generation; use in well-ventilated areas

- Storage Measures: Keep container sealed and dry

- First Aid Measures

- Inhalation: Move to fresh air; seek medical attention if respiratory symptoms develop

- Skin Contact: Wash with soap and water; seek medical attention if irritation occurs

- Eye Contact: Rinse immediately with plenty of water for at least 15 minutes; consult a physician if irritation persists

- Ingestion: Rinse mouth; low toxicity but seek medical advice if large quantities are swallowed

- Firefighting Measures

- Fire Hazards: Combustible solid; burns with a yellow flame

- Extinguishing Media: Water spray, foam, dry chemical, CO₂

- Special Precautions: Avoid inhalation of smoke; wear protective equipment

- Decomposition Products: Carbon monoxide, carbon dioxide, and other toxic fumes

Related products

Cellulose Ether

Cellulose ether refers to a group of chemically modified cellulose derivatives where hydroxyl groups on the cellulose backbone are substituted with ether groups such as methyl, hydroxyethyl, or carboxymethyl groups. These modifications improve solubility, viscosity, and film-forming properties while maintaining biodegradability and non-toxicity. Cellulose ethers are white to off-white powders or granules that dissolve in water to form viscous, stable solutions. They are widely used as thickeners, binders, stabilizers, and film formers in industries such as construction, pharmaceuticals, cosmetics, food, and paper.

Cetyl Alcohol 98% Flakes

Cetyl Alcohol Flakes is a high-purity fatty alcohol derived mainly from natural sources such as palm oil and coconut oil. Presented as white to off-white waxy flakes, this product contains at least 98% pure cetyl alcohol, ensuring consistent performance and quality. It is valued for its excellent emollient, thickening, and emulsifying properties and is widely used in personal care, pharmaceutical, and industrial formulations. The flake form facilitates easy handling, melting, and dosing in manufacturing processes. Cetyl Alcohol 98% Flakes contributes to the texture, stability, and moisturizing properties of various formulations, providing a non-greasy, smooth finish.

Dimethicone Silicon Oil

Dimethicone Silicon Oil, also known as polydimethylsiloxane (PDMS) or silicone oil, is a clear, odorless, and non-volatile silicone-based polymer widely used for its lubricating, anti-foaming, water-repellent, and skin-conditioning properties. It is a linear silicone polymer composed of repeating dimethylsiloxane units. Dimethicone exhibits excellent thermal stability, chemical inertness, and low surface tension, making it highly versatile in pharmaceutical, cosmetic, personal care, industrial, and food applications. It is available in various viscosities, from very low to high viscosity oils, enabling tailored formulations.

Fish Collagen

Fish Collagen is a natural protein derived from the skin, scales, and bones of various fish species through enzymatic hydrolysis or acid extraction. It is predominantly Type I collagen, known for its excellent bioavailability and biocompatibility. Fish Collagen typically appears as a fine white to off-white powder with low odor and high solubility in water and acidic solutions. It is widely prized in cosmetics, nutraceuticals, pharmaceuticals, and food industries due to its superior absorption compared to mammalian collagen, making it highly effective in skin, joint, and bone health applications. Fish Collagen supports the body’s extracellular matrix, promoting skin elasticity, hydration, and tissue repair.

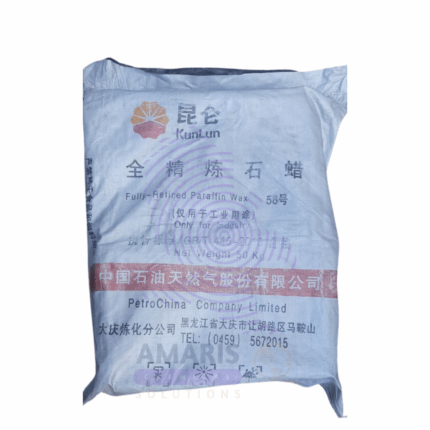

Fully Refined Paraffin Wax

Fully Refined Paraffin Wax is a highly purified, odorless, white to pale yellow wax obtained from the refining of petroleum-derived crude paraffin wax. It consists primarily of saturated hydrocarbons (alkanes) with chain lengths typically between C20 and C40. Due to its excellent chemical stability, non-toxicity, and versatility, Fully Refined Paraffin Wax is widely used across numerous industries including cosmetics, pharmaceuticals, food packaging, candle making, rubber processing, and electrical insulation. It exhibits a high melting point, low volatility, and good water resistance.

Glycerol Monostearate Flakes

Glycerol Monostearate Flakes is a white to off-white waxy flake form emulsifier composed of 40% monoglycerides of fatty acids, primarily stearic and palmitic acids, combined with other glycerides and esters. Derived mainly from vegetable oils, this food-grade emulsifier is widely utilized in food, cosmetic, pharmaceutical, and industrial sectors for its multifunctional properties. GMS 40% flakes serve as effective emulsifiers, stabilizers, anti-caking agents, and texture enhancers, with excellent compatibility and versatility in formulations requiring semi-solid or solid fats.

Hycryl

Hycryl is a specialized acrylic copolymer resin designed primarily for industrial and cosmetic applications. It appears as a white to off-white powder or granules with excellent film-forming, adhesive, and thickening properties. Known for its compatibility with a wide range of solvents and plasticizers, Hycryl 77 provides excellent clarity, flexibility, and durability in coatings, adhesives, and personal care formulations. Its balanced molecular weight and functional groups enable it to deliver strong binding and aesthetic properties in both aqueous and solvent-based systems.

Hydroxyethyl Cellulose

Hydroxyethyl Cellulose , marketed under brand names such as Natrosol, is a non-ionic, water-soluble polymer derived from cellulose by reacting alkali cellulose with ethylene oxide. It appears as a white to off-white, free-flowing powder with excellent thickening, binding, and film-forming properties. HEC is widely used as a rheology modifier and stabilizer due to its high water retention, solubility, and compatibility with a broad range of ingredients. It is valued in many industries including cosmetics, pharmaceuticals, paints, adhesives, and personal care products.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders