“Corn Starch Industrial Grade” has been added to your cart. View cart

Master Cast

Whatsapp Order

Master Cast is a high-quality gypsum-based casting material designed for producing precise and durable molds, prototypes, and decorative castings. It offers excellent flowability, rapid setting time, and high strength after curing. Master Cast is widely used in ceramics, sculpture, dentistry, and industrial mold-making applications where fine detail reproduction and surface smoothness are critical.

Category: Admixtures

Tags: Concrete additive, Concrete casting aid, Construction chemical, MasterCast, Surface hardener

Description

Table of Contents

Toggle

Master Cast

Primary Uses

- Ceramics and Sculpture

- Mold Making: Used for creating detailed molds for ceramic art, pottery, and sculptural pieces.

- Casting: Produces fine, accurate castings for artistic and decorative applications.

- Dental Applications

- Dental Models: Used for making precise dental molds, impressions, and study casts.

- Industrial Prototyping

- Prototype Production: Ideal for rapid prototyping and model making in manufacturing and design.

- Pattern Making: Used to create patterns for metal casting and other fabrication processes.

Secondary Uses

- Architectural and Decorative

- Ornamental Casting: Suitable for producing decorative elements like cornices, moldings, and statues.

- Educational Uses

- Teaching Aid: Used in schools and colleges for training in mold-making and casting techniques.

PRODUCT KEY FEATURES

- Basic Identification Attributes

- Chemical Name (IUPAC): Calcium sulfate hemihydrate

- Common/Trade Name: Master Cast

- CAS Number: 13397-24-5

- HS Code: 2520.10.00 (Gypsum; anhydrite)

- Synonyms: Plaster of Paris; gypsum powder; casting plaster

- Physical & Chemical Properties

- Physical State: Fine white powder

- Color & Odor: White; odorless

- Setting Time: Rapid setting, typically 5–15 minutes

- Strength: High compressive strength after curing

- Solubility: Slightly soluble in water

- Density: Approximately 0.9–1.0 g/cm³

- Safety & Hazard Attributes

- GHS Classification: Not classified as hazardous under normal use

- Toxicity: Low toxicity; inhalation of dust may cause irritation

- Exposure Limits: Avoid inhalation of dust; use appropriate PPE

- Storage & Handling Attributes

- Storage Conditions: Store in a dry, well-ventilated area away from moisture

- Container Type: Supplied in sealed bags or cartons

- Shelf Life: 12 months if stored properly

- Handling Precautions: Avoid dust inhalation; use dust mask and gloves

- Regulatory & Compliance Attributes

- Complies with relevant safety and quality standards for gypsum products

- Environmental & Health Impact

- Biodegradability: Not applicable

- Ecotoxicity: Low environmental impact when disposed properly

- Bioaccumulation: Not expected

SAFETY HANDLING PRECAUTIONS

- Safety Handling Precautions

PPE Required:

- Dust mask, gloves, and safety goggles during handling

Handling Guidelines:

- Avoid dust generation; handle in well-ventilated areas

Storage Measures:

- Keep bags sealed and dry to prevent clumping

- First Aid Measures

- Inhalation: Move to fresh air; seek medical attention if respiratory irritation persists

- Skin Contact: Wash with water and soap; seek medical advice if irritation develops

- Eye Contact: Rinse immediately with plenty of water; consult a physician if irritation continues

- Ingestion: Rinse mouth; seek medical attention if symptoms occur

- Firefighting Measures

- Fire Hazards: Non-flammable

- Extinguishing Media: Use extinguishing media suitable for surrounding materials

- Special Precautions: None specific to Master Cast

- Hazardous Combustion Products: None

Related products

Calcium Chloride Dihydrate

Calcium Chloride Dihydrate (CaCl₂·2H₂O) is a hydrated form of calcium chloride, appearing as white crystalline granules or flakes containing two molecules of water of crystallization. It is highly soluble in water and exhibits strong hygroscopic and deliquescent properties. This compound is widely used in industrial, pharmaceutical, food, and agricultural sectors due to its moisture absorption, de-icing, dust control, and calcium supplementation capabilities. Compared to anhydrous calcium chloride, the dihydrate form has lower hygroscopicity but is easier to handle and store.

Caustic Soda Pearls

Caustic Soda Pearls are small, solid, spherical particles of sodium hydroxide (NaOH) produced by a controlled cooling and solidification process. These pearls offer superior flowability, uniform size distribution, and reduced dust generation compared to flake or powder forms. They are highly soluble in water, exhibiting a strong alkaline nature with vigorous exothermic dissolution. Caustic Soda Pearls are widely used across industries including chemical manufacturing, water treatment, pulp and paper processing, and detergents due to their purity, ease of handling, and efficient dissolution characteristics.

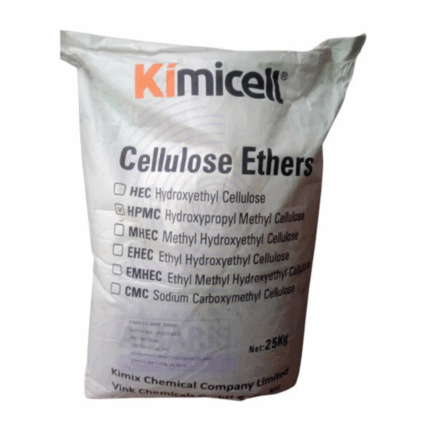

Cellulose Ether

Cellulose ether refers to a group of chemically modified cellulose derivatives where hydroxyl groups on the cellulose backbone are substituted with ether groups such as methyl, hydroxyethyl, or carboxymethyl groups. These modifications improve solubility, viscosity, and film-forming properties while maintaining biodegradability and non-toxicity. Cellulose ethers are white to off-white powders or granules that dissolve in water to form viscous, stable solutions. They are widely used as thickeners, binders, stabilizers, and film formers in industries such as construction, pharmaceuticals, cosmetics, food, and paper.

CMC Sodium Blanose

CMC Sodium Blanose is a high-purity, pharmaceutical- and food-grade Sodium Carboxymethyl Cellulose (CMC), manufactured under the Blanose® brand by Ashland or equivalent producers. It is a water-soluble, anionic cellulose ether derived from natural cellulose, designed for superior consistency, clarity, and performance. CMC Blanose serves as a thickening agent, stabilizer, binder, film former, and emulsifier in a wide variety of applications. Known for its excellent rheological control and water retention, it is widely used across the food, pharmaceutical, personal care, and industrial sectors, offering reliable performance with batch-to-batch consistency.

Eagle Homopolymer 510/50 50%

Eagle Homopolymer 510/50 50% is a high-purity homopolymer solution, typically referring to polyvinyl alcohol (PVA) or a similar water-soluble polymer supplied at 50% concentration. This product offers excellent film-forming, adhesive, thickening, and stabilizing properties, making it versatile in applications such as adhesives, textile sizing, paper coating, and packaging. The homopolymer’s controlled molecular weight and solution viscosity provide consistent performance and ease of handling. The 50% aqueous solution form facilitates easy mixing and incorporation into various formulations.

Eagle Styrene Acrylic 72/50

Eagle Styrene Acrylic 72/50 is a co-polymer emulsion consisting of styrene and acrylic monomers, offered at 50% active solids concentration in water. It appears as a milky-white, low-viscosity liquid with a mild odor. This polymer emulsion combines excellent film-forming properties, adhesion, and mechanical strength, making it widely used in coatings, adhesives, sealants, and functional binders across multiple industries.

Master Air

Master Air is a high-performance air release agent used primarily in concrete and construction applications. It facilitates the release of entrapped air bubbles from fresh concrete mixtures, improving workability, surface finish, and durability. This additive enhances the homogeneity of concrete by reducing air voids that can weaken the structure. Master Air is suitable for use in ready-mix concrete, precast elements, and other cementitious materials, contributing to improved mechanical properties and longevity of the final product.

Medium Binder

Medium Binder is a versatile adhesive and binding agent formulated to enhance cohesion, strength, and durability in various industrial and construction applications. It improves the bonding properties between different materials, providing a reliable and consistent bond that resists environmental degradation. Medium Binder is suitable for use in composites, coatings, and concrete formulations, optimizing performance and structural integrity.

Acidulants

Acidulants Antioxidants

Antioxidants Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food)

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders