Back to products

Ferric Chloride Anhydrous

$ 1.15 Original price was: $ 1.15.$ 1.02Current price is: $ 1.02.

Nitro Cellulose

Whatsapp Order

Nitro Cellulose is a highly flammable compound produced by nitrating cellulose through exposure to nitric acid and sulfuric acid. It is a versatile material widely used in coatings, lacquers, explosives, and propellants due to its film-forming properties and rapid drying capability. Nitro Cellulose is available in various grades depending on the nitrogen content and viscosity, making it suitable for industrial, commercial, and military applications.

Category: Binders/Resins

Tags: Cellulose Nitrate, Fast Drying, NC, Nitro Cellulose, Paints & Coatings

Description

Table of Contents

Toggle

Nitro Cellulose

Primary Uses

- Coatings and Lacquers

- Used extensively in wood finishes, automotive coatings, and nail polishes for its quick drying and glossy finish properties.

- Serves as a binder in paints and varnishes.

- Explosives and Propellants

- Key ingredient in smokeless gunpowder and other propellants due to its high energy release and clean combustion.

- Used in military ammunition and pyrotechnics.

- Printing Inks

- Used as a binder in flexographic and gravure printing inks.

- Provides excellent adhesion and gloss to printed materials.

- Adhesives and Films

- Utilized in adhesive formulations for packaging and lamination.

- Forms thin, flexible films in photographic and industrial applications.

Secondary Uses

- Cosmetics

- Used in nail polish and hair sprays as a film-forming agent.

- Leather Finishing

- Provides protective coatings on leather goods.

- Textile Finishing

- Applied as a sizing agent or finish to improve fabric strength and sheen.

- Specialty Applications

- Used in the manufacture of cellulose-based plastics and lacquers for musical instruments and toys.

KEY PRODUCT FEATURES

1. Basic Identification Attributes

- Chemical Name (IUPAC): Cellulose nitrate

- Common/Trade Name: Nitro Cellulose, Gun Cotton

- CAS Number: 9004-70-0

- HS Code: 3912.10.00

- Synonyms: Pyroxylin, guncotton

2. Physical & Chemical Properties

- Physical State: White to pale yellow fibrous or granular solid

- Odor: Mild acidic odor

- Nitrogen Content: Typically 11-13% (varies by grade)

- Solubility: Soluble in acetone, ether, ethanol; insoluble in water

- Density: Approx. 1.6 g/cm³

- Flammability: Highly flammable and explosive under certain conditions

3. Safety & Hazard Attributes

- GHS Classification: Flammable solids (Category 1), Explosive (varies by grade)

- Toxicity: Moderate; dust inhalation can cause irritation

- Exposure Limits: Use in controlled environments to limit dust and vapors

4. Storage & Handling Attributes

- Storage Conditions: Store in a cool, dry, well-ventilated area away from heat, sparks, and open flames

- Container Type: Supplied in sealed, non-metallic containers or drums

- Shelf Life: Typically 1–2 years under proper storage

- Handling Precautions: Avoid friction, impact, static discharge; use explosion-proof equipment

5. Regulatory & Compliance Attributes

- Complies with military and industrial standards for explosives and coatings

- Subject to strict transport regulations due to explosive potential

- Registered under relevant chemical safety and explosives control laws

6. Environmental & Health Impact

- Biodegradability: Partially biodegradable under environmental conditions

- Ecotoxicity: Low environmental risk when handled properly

- Bioaccumulation: Not expected to bioaccumulate

- Carcinogenicity/Mutagenicity: Not classified as carcinogenic

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- PPE Required: Flame-resistant clothing, gloves, eye protection, and respiratory protection if dusty

- Handling Guidelines: Use grounding and bonding to prevent static; avoid open flames

- Storage Measures: Segregate from incompatible materials such as acids and reducing agents

First Aid Measures

- Inhalation: Move to fresh air; seek medical attention if respiratory symptoms persist

- Skin Contact: Wash with soap and water; seek medical help if irritation occurs

- Eye Contact: Rinse immediately with water for 15 minutes; consult a physician if irritation continues

- Ingestion: Do not induce vomiting; seek medical advice promptly

Firefighting Measures

- Fire Hazards: Highly flammable and explosive under heat or friction

- Extinguishing Media: Use water spray or fog; do not use dry chemical extinguishers on large fires

- Special Precautions: Evacuate area; wear full protective and respiratory equipment

- Hazardous Combustion Products: Nitrogen oxides, carbon monoxide, and other toxic gases

Related products

Acrytan SN

Bentonite Powder

Bentonite powder is a naturally occurring absorbent clay primarily composed of montmorillonite, a type of smectite clay mineral. It exhibits excellent swelling and water absorption properties, making it highly versatile in industrial and commercial applications. Bentonite forms a gel-like substance when mixed with water, which imparts viscosity and plasticity. It is used extensively for its binding, sealing, and adsorptive characteristics. Its fine powder form allows for easy incorporation in various processes including drilling, foundry, cosmetics, pharmaceuticals, and agriculture.

Domacryl

Domacryl is a high-performance acrylic polymer latex designed for use as a binder in water-based coatings, adhesives, sealants, and construction materials. It is a styrene-acrylic copolymer emulsion offering excellent film formation, adhesion, durability, and chemical resistance. Domacryl provides superior mechanical strength and flexibility in formulated products, making it ideal for applications requiring long-lasting protection and enhanced aesthetic qualities. The polymer is supplied as a stable aqueous dispersion with approximately 50% solids content, packed in bulk (190 kg drums) for industrial use.

Hycryl

Hycryl is a specialized acrylic copolymer resin designed primarily for industrial and cosmetic applications. It appears as a white to off-white powder or granules with excellent film-forming, adhesive, and thickening properties. Known for its compatibility with a wide range of solvents and plasticizers, Hycryl 77 provides excellent clarity, flexibility, and durability in coatings, adhesives, and personal care formulations. Its balanced molecular weight and functional groups enable it to deliver strong binding and aesthetic properties in both aqueous and solvent-based systems.

Latex

Latex is a natural or synthetic colloidal dispersion of polymer microparticles in an aqueous medium. Natural latex is harvested from rubber trees (Hevea brasiliensis) and appears as a milky fluid rich in rubber particles suspended in water. Synthetic latexes are produced from various monomers such as styrene-butadiene or acrylics. Latex exhibits excellent elasticity, flexibility, and adhesive properties. It is widely used in manufacturing gloves, balloons, coatings, adhesives, paints, and various molded products. Its film-forming ability, water resistance, and durability make it a versatile material across industries.

Long Oil

Long Oil refers to oils with a high content of unsaturated fatty acids, particularly linoleic and linolenic acids, commonly derived from drying oils such as linseed, soybean, or safflower oil. These oils have extended drying times and are used in various industrial applications where slow curing and flexible film formation are desired. Long oil is a key component in producing long oil alkyd resins, which are widely used in coatings, paints, varnishes, and printing inks due to their excellent adhesion, flexibility, and durability.

Penetrator Binder

Penetrator Binder is a high-performance binding agent designed to improve the adhesion and penetration of coatings, adhesives, and sealants into porous substrates. It enhances substrate wettability and strengthens the bond between the applied material and the surface, resulting in improved durability and performance. Penetrator Binder is commonly used in construction, wood treatment, and industrial coatings to ensure better material integration and resistance to environmental factors.

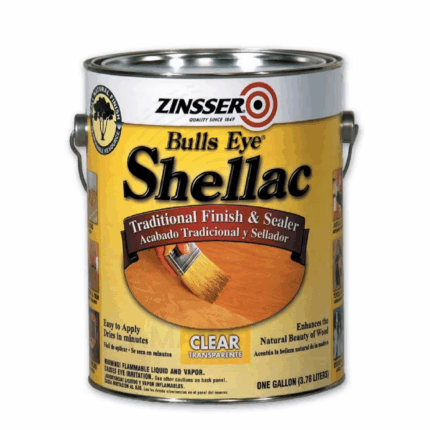

Shellac

Shellac is a natural resin secreted by the lac insect, primarily found in South Asia. It is processed into flakes or powder form and dissolved in alcohol to create a versatile film-forming agent. Shellac provides excellent adhesion, gloss, and moisture resistance, making it widely used as a wood finish, food glaze, and pharmaceutical coating. It is valued for its natural origin, biodegradability, and safe use in food and cosmetic applications.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders