Sodium Diphenylamin Sulphonate

Whatsapp Order

Sodium Diphenylamin Sulphonate is a white to light brown crystalline powder used primarily as an antioxidant and stabilizer in various industrial applications. It functions by inhibiting the oxidation of materials such as rubber, lubricants, and fuels, thereby enhancing their shelf life and performance. This chemical is valued for its efficiency in preventing degradation caused by heat, light, and oxygen exposure. It also finds use as a reagent in analytical chemistry and in dye manufacturing processes.

Description

Table of Contents

Toggle

Sodium Diphenylamin Sulphonate

Primary Uses

- Rubber Industry

- Acts as an antioxidant and anti-degradant to prevent premature aging and cracking of rubber products.

- Improves the durability and lifespan of tires, hoses, and other rubber goods.

- Lubricants and Fuels

- Used as a stabilizer to prevent oxidation and maintain the quality of oils, greases, and fuels during storage and use.

- Dye and Pigment Industry

- Serves as an intermediate in the synthesis of dyes and pigments.

- Used as a reagent to enhance color stability and consistency.

- Analytical Chemistry

- Employed as an indicator or reagent in certain chemical assays and laboratory tests.

Secondary Uses

- Polymer Additives

- Incorporated in various polymer formulations to improve resistance against thermal and oxidative degradation.

- Metal Processing

- Sometimes used as a corrosion inhibitor in metalworking fluids and cooling lubricants.

KEY PRODUCT FEATURES

1. Basic Identification Attributes

- Chemical Name (IUPAC): Sodium 4-(phenylamino)benzenesulfonate

- Common/Trade Name: Sodium Diphenylamin Sulphonate

- CAS Number: 15325-10-5

- HS Code: 2921.49

- Synonyms: Sodium diphenylamine sulfonate, Sodium 4-aminodiphenyl sulfonate

2. Physical & Chemical Properties

- Physical State: Powder or crystalline solid

- Color & Odor: White to light brown; odorless

- Solubility: Soluble in water

- Density: Approx. 1.4 g/cm³

3. Safety & Hazard Attributes

- GHS Classification: May cause skin and eye irritation

- Toxicity: Low toxicity but avoid prolonged exposure

- Exposure Limits: Use appropriate industrial hygiene measures to minimize dust exposure

4. Storage & Handling Attributes

- Storage Conditions: Store in a cool, dry, well-ventilated place, protected from moisture and incompatible substances

- Container Type: Typically supplied in sealed plastic or fiber drums

- Shelf Life: Stable if stored under recommended conditions

- Handling Precautions: Use protective equipment; avoid dust generation and inhalation

- Storage Measures: Keep containers tightly closed and stored in a dry environment

5. Regulatory & Compliance Attributes

- Complies with industrial chemical safety regulations

- Used in formulations compliant with regional and international standards for antioxidants and stabilizers

6. Environmental & Health Impact

- Biodegradability: Not readily biodegradable

- Ecotoxicity: Should be handled to avoid environmental release; may be harmful to aquatic life at high concentrations

- Bioaccumulation: Not expected to bioaccumulate

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- PPE Required: Gloves, goggles, and dust mask recommended

- Handling Guidelines: Avoid inhalation and contact with skin or eyes; ensure good ventilation

- Storage Measures: Store away from strong oxidizers and moisture

First Aid Measures

- Inhalation: Move to fresh air; seek medical attention if irritation occurs

- Skin Contact: Wash thoroughly with soap and water; get medical advice if irritation develops

- Eye Contact: Rinse immediately with plenty of water for 15 minutes; seek medical attention if irritation persists

- Ingestion: Rinse mouth; seek medical attention if significant ingestion occurs

Firefighting Measures

- Fire Hazards: Non-flammable but may decompose under fire conditions producing toxic fumes

- Extinguishing Media: Water spray, foam, dry chemical, or CO₂

- Special Precautions: Wear full protective equipment and self-contained breathing apparatus

- Hazardous Combustion Products: Sulfur oxides, nitrogen oxides, and other toxic fumes

Related products

Dimethyl Acetimide

Dimethyl Acetimide is a versatile organic compound used predominantly as a solvent and intermediate in chemical syntheses. It is a colorless to pale yellow liquid with good solvency properties for a wide range of organic substances. Known for its stability and relatively low toxicity compared to similar amides, Dimethyl Acetimide finds applications in pharmaceuticals, agrochemicals, and specialty chemical manufacturing. Its miscibility with water and many organic solvents makes it suitable for formulation and processing roles.

Isopropyl Alcohol Tech Grade

Isopropyl Alcohol Tech Grade is a colorless, flammable liquid with a strong, characteristic alcohol odor. It is a solution containing approximately 85% isopropanol by volume, with the remainder primarily water. This technical-grade IPA is widely used as a solvent, disinfectant, and cleaning agent in industrial, pharmaceutical, and household applications. The 85% concentration balances efficacy with safety and evaporation rate, making it versatile for various uses.

Liquid Pineapple Flavor

Liquid Pineapple Flavor (Food Grade) is a high-quality, natural and synthetic flavoring agent designed to capture the sweet, tangy, and refreshing taste of ripe pineapple. Widely used in the food and beverage industry, this flavor enhances a variety of products such as soft drinks, juices, confectionery, dairy, and baked goods. It is water and alcohol soluble, providing versatility in formulation. Its vibrant tropical aroma and authentic pineapple taste help create appealing and flavorful consumer products.

Mango Liquid Flavor

Mango Liquid Flavor Food Grade is a vibrant and natural-tasting flavoring agent that replicates the sweet, juicy, and tropical essence of ripe mangoes. This high-quality liquid flavor is specially formulated for use in food and beverage applications, providing a consistent and authentic mango aroma and taste. Its excellent solubility and stability make it ideal for use in beverages, confectionery, dairy products, baked goods, and other food formulations, enhancing product appeal with a fresh tropical note.

Normal Hexane

Normal Hexane is a colorless, highly flammable liquid hydrocarbon with the chemical formula C6H14. It belongs to the aliphatic hydrocarbon family and is primarily used as a solvent due to its excellent ability to dissolve oils, fats, and various organic compounds. It has a low boiling point and evaporates quickly, making it ideal for industrial and laboratory applications.

Orange Fragrance Oil

Orange Fragrance Oil is a highly concentrated aromatic oil that delivers a fresh, vibrant, and sweet citrus scent reminiscent of ripe oranges. It is formulated for use in a variety of applications including personal care products, household items, and air fresheners. This fragrance oil offers excellent scent throw, stability, and compatibility with different base materials such as waxes, solvents, and emulsions. Its refreshing aroma makes it a popular choice for perfuming soaps, candles, detergents, and cosmetic formulations, providing a natural and uplifting citrus experience.

Passion Fruit Fragrance Oil

Passion Fruit Fragrance Oil is a vibrant, richly scented oil delivering the sweet, exotic aroma of ripe passion fruit. Ideal for enhancing personal care products, perfumes, and home fragrances, this fragrance oil provides a long-lasting, fresh tropical scent. It is crafted to blend smoothly into oil-based and solvent-based formulations, ensuring consistent fragrance delivery. Manufactured under stringent quality controls, Passion Fruit Fragrance Oil adds a luxurious and refreshing note to a wide range of applications.

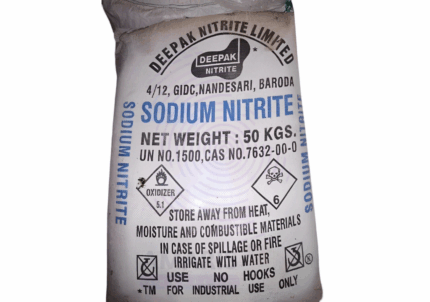

Sodium Nitrite

Sodium Nitrite is an inorganic white to slightly yellowish crystalline powder with the chemical formula NaNO₂. This versatile chemical serves as a powerful reducing agent, corrosion inhibitor, and food preservative, widely used in meat curing, pharmaceutical synthesis, and industrial applications. Its oxidative properties make it valuable for dye manufacturing and rubber processing while requiring careful handling due to its toxicity.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders