Thinner

Thinner is a volatile solvent or a blend of solvents formulated to reduce the viscosity of paints, coatings, lacquers, and varnishes for improved application properties. It enhances flow, leveling, drying time, and finish quality. Thinners are available in different grades tailored to specific resins or coatings—such as nitrocellulose, alkyd, polyurethane, or epoxy systems—and are crucial in industrial, automotive, wood, and general-purpose applications.

Primary Uses

Paints & Coatings Industry

Viscosity Reduction: Essential for diluting paints, primers, and varnishes to achieve desired spray or brush application consistency.

Application Aid: Improves flow, leveling, and finish smoothness during brush, roller, or spray application.

Surface Preparation: Used to clean surfaces before painting to remove grease, oil, or dirt.

Tool Cleaning: Cleans paint equipment like spray guns, brushes, rollers, and containers after use.

Paint Removal: Acts as a stripping agent for removing old or excess coatings.

Automotive Industry

Automotive Paint Systems: Used with acrylic, polyurethane, and enamel paints for car refinishing, basecoats, and clearcoats.

Blending Solvent: Assists in blending new paint with existing paint for seamless repairs.

Pre-cleaning Solvent: Prepares metal or plastic car parts before coating or refinishing.

Wood & Furniture Finishing

Wood Lacquers and Varnishes: Thinner is used to reduce viscosity of shellac, lacquer, and polyurethane coatings applied to wood furniture and cabinetry.

Grain Highlighting: Helps penetrate wood grains during staining and enhances depth and clarity of finishes.

Secondary Uses

Printing Inks & Signage

Ink Diluent: Used in thinning solvent-based inks for screen printing and flexography.

Stencil Cleaning: Cleans screens, plates, and equipment used in solvent-based printing.

Industrial Manufacturing

Equipment Cleaning: Removes greases, oil residues, and adhesives from machines and production lines.

Chemical Blending: Serves as a carrier or intermediate solvent in custom chemical blends.

Marine & Aerospace Coatings

Marine Paints: Used in thinning marine-grade paints and antifouling coatings.

Aircraft Coatings: Part of solvent systems for applying aviation-specific coatings.

Art & DIY

Artists’ Paints: Dilutes oil-based or alkyd-based paints for fine art applications.

Craft Projects: Used in various home-improvement and craft projects involving oil-based products

Basic Identification Attributes

Chemical Name (Varies by composition): May include toluene, xylene, acetone, MEK, IPA, ethyl acetate, or white spirit

Common/Trade Name: Thinner, Paint Thinner, Solvent Blend

CAS Number: Varies by formulation

HS Code: 3814.00.00 (Organic composite solvents and thinners)

Synonyms: Paint reducer, solvent blend, lacquer thinner, reducer

Physical & Chemical Properties

Physical State: Clear, volatile liquid

Color & Odor: Colorless to pale yellow; strong solvent odor

Boiling Point: Varies (typically 60–180 °C depending on solvent blend)

Flash Point: Typically < 25 °C (depends on formulation)

Solubility: Insoluble in water; miscible with organic solvents

Vapor Pressure: High (volatile compound)

Density: 0.75–0.90 g/cm³ (depends on formulation)

Safety & Hazard Attributes

GHS Classification: Flammable liquid, harmful by inhalation, eye/skin irritant

Toxicity: Moderate to high acute toxicity depending on solvent type (toluene, MEK, etc.)

Exposure Limits: OSHA PEL and ACGIH TLV apply for individual components (e.g., toluene: 20 ppm TLV)

Storage & Handling Attributes

Storage Conditions: Store in a cool, well-ventilated area away from heat, sparks, and open flames

Container Type: Metal drums, sealed cans, or solvent-resistant plastic containers

Shelf Life: 12–24 months if unopened and properly stored

Handling Precautions: Use non-sparking tools; ensure adequate ventilation; avoid static discharge

Regulatory & Compliance Attributes

Regulated under OSHA, REACH, TSCA, and GHS standards

Classified as a flammable and hazardous material for transport (UN 1263 – Paint Related Material)

Complies with local VOC regulations (where applicable)

Proper labeling and SDS (Safety Data Sheet) required for all handling and transport

Environmental & Health Impact

Biodegradability: Limited; varies by solvent blend

Ecotoxicity: Harmful to aquatic life; avoid environmental release

Bioaccumulation: Possible for aromatic solvents (e.g., toluene, xylene)

PPE Required: Chemical-resistant gloves, goggles, flame-resistant lab coat, respirator (if ventilation is poor)

Handling Guidelines: Avoid inhalation and skin contact; use with spark-proof equipment

Storage Measures: Store in approved flammable liquid storage cabinets or areas

First Aid Measures

Inhalation: Remove to fresh air; seek medical attention if breathing difficulty persists

Skin Contact: Wash thoroughly with soap and water

Eye Contact: Flush eyes with water for 15 minutes; seek medical help if irritation continues

Ingestion: Do not induce vomiting; seek immediate medical attention

Firefighting Measures

Fire Hazards: Highly flammable

Extinguishing Media: Foam, dry chemical, CO₂; avoid using water jets

Hazardous Combustion Products: Carbon monoxide, carbon dioxide, and various organic vapors

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

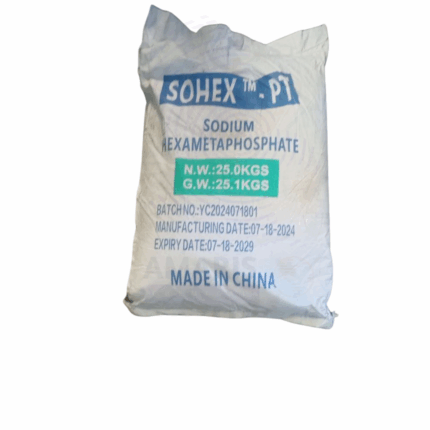

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

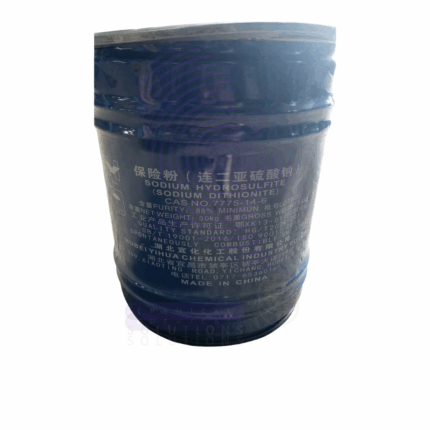

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders