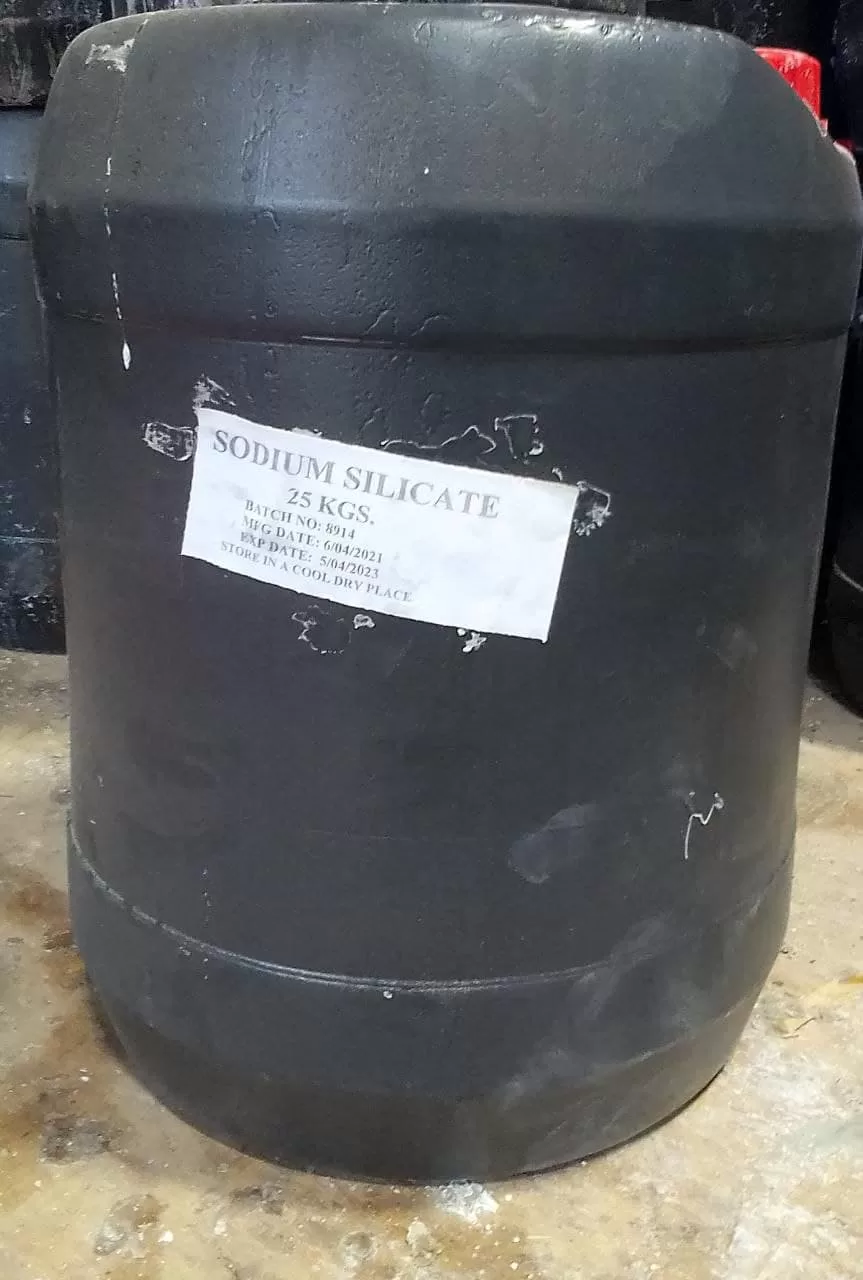

Sodium Silicate: The Key Ingredient Transforming Manufacturing Processes

Sodium silicate, often referred to as water glass, is a versatile chemical compound that has become indispensable in modern manufacturing processes. Its applications span across industries, from construction to automotive, making it a cornerstone in various production methods. Composed of sodium oxide and silica, sodium silicate’s unique properties, such as high heat resistance, adhesive qualities, and alkaline nature, make it a valuable resource for a wide array of applications.

In the Construction Industry

One of the most significant uses of sodium silicate is in the construction industry, where it serves as an essential component in the creation of cements, fireproofing materials, and waterproof coatings. Sodium silicate helps improve the durability and strength of concrete, making it ideal for both residential and commercial projects. Additionally, it forms an integral part of fire-resistant coatings, protecting structures from high temperatures.

A Game-Changer in Manufacturing

In manufacturing, sodium silicate is employed as a binder in foundry operations. It plays a crucial role in molding processes, where it is used to create molds and cores in metal casting. The binder properties of sodium silicate ensure that the molds are both durable and capable of withstanding high temperatures, which are critical in the production of metals like aluminum and steel.

Sustainability in Modern Processes

Sodium silicate’s eco-friendly nature is another reason why it is increasingly favored by manufacturers. Unlike other chemicals that may emit harmful fumes or contribute to pollution, sodium silicate is non-toxic and environmentally safe when used properly. This makes it a sustainable choice in processes where safety and environmental concerns are a priority.

Water Treatment and Detergent Formulation

Beyond construction and manufacturing, sodium silicate is used in water treatment processes, where it acts as a corrosion inhibitor and helps in the removal of heavy metals. It is also a key ingredient in many detergent formulations, enhancing cleaning efficiency by breaking down grease and dirt.

Conclusion

Sodium silicate’s wide-ranging uses across various industries highlight its significance in transforming manufacturing processes. From improving the strength of construction materials to contributing to environmentally friendly production methods, sodium silicate is undeniably a vital compound that continues to shape the future of manufacturing. Its versatility and sustainability make it a key player in the ongoing evolution of industrial production.

LABORATORY EQUIPMENT & APPARATUS

LABORATORY EQUIPMENT & APPARATUS

Fertilizers

Fertilizers Plant Growth Regulators

Plant Growth Regulators Soil Conditioners

Soil Conditioners Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Preservatives (baking)

Preservatives (baking)

Surfactants (cleaning)

Surfactants (cleaning) Builders

Builders Bleaching Agents

Bleaching Agents Enzymes

Enzymes Solvents (cleaning)

Solvents (cleaning) Fragrances

Fragrances