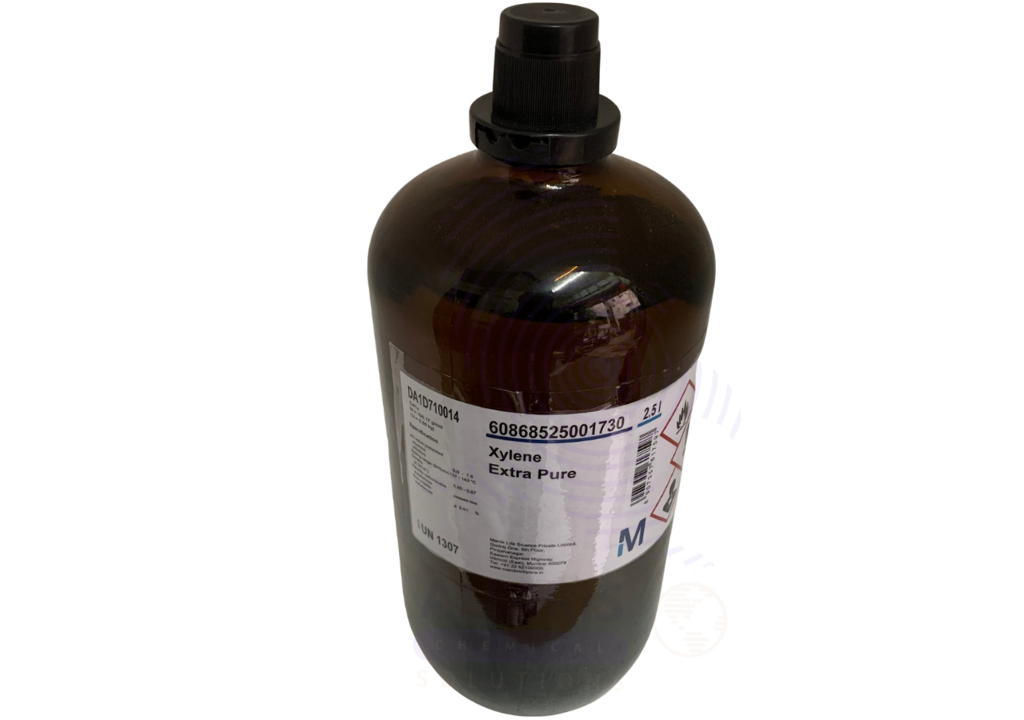

Xylene: The Versatile Industrial Solvent Powering Modern Manufacturing 🧪⚙️

When it comes to industrial solvents, few chemicals match the versatility and performance of Xylene. Known for its exceptional ability to dissolve, clean, and blend, Xylene plays a crucial role across paint, coatings, rubber, adhesive, and printing industries. Its unique balance of solvency strength and controlled evaporation makes it a cornerstone in modern chemical processing.

At Amaris Chemical Solutions, we understand how essential reliable solvents are to achieving high-quality production results. Let’s explore what makes Xylene so valuable and how it continues to shape industrial chemistry.

🌟 What is Xylene?

Xylene (also called dimethylbenzene) refers to a group of aromatic hydrocarbons consisting of three isomers—ortho-, meta-, and para-xylene. These colorless, sweet-smelling liquids are typically derived from petroleum or coal tar during the refining process.

Chemically, Xylene is known for its excellent solvency power, making it capable of dissolving a wide range of resins, dyes, and polymers that are otherwise insoluble in other organic solvents.

🔬 Physical and Chemical Properties

- Appearance: Clear, colorless liquid

- Odor: Sweet, aromatic

- Boiling Point: 137–144°C (depending on isomer)

- Solubility: Insoluble in water, but miscible with alcohol, ether, and many organic solvents

- Flash Point: Around 25°C (closed cup) – Flammable

- Density: Approximately 0.86 g/cm³

These properties make Xylene a powerful and adaptable solvent for both industrial and laboratory use.

🏭 Major Industrial Applications of Xylene

1. Paints, Coatings, and Varnishes 🎨

Xylene is widely used as a solvent and thinner in paints and varnishes to adjust viscosity, improve flow, and ensure a smooth finish. Its moderate evaporation rate helps maintain even drying without leaving residue or bubbles.

2. Printing Inks and Adhesives 🖨️

Due to its compatibility with various resins and polymers, Xylene is a key ingredient in ink formulations and industrial adhesives, providing the right consistency and adhesion strength.

3. Rubber and Leather Industries 👟

In rubber processing, Xylene aids in dissolving and softening polymers, making it ideal for producing flexible, durable materials. It’s also used in leather finishing for achieving uniform surface coatings.

4. Chemical Intermediates ⚗️

Xylene is an important raw material in the manufacture of terephthalic acid (TPA) and dimethyl terephthalate (DMT)—both essential in producing polyethylene terephthalate (PET) plastics and fibers.

5. Cleaning and Degreasing Agent 🧼

Industrially, Xylene acts as a strong degreaser for cleaning metal surfaces, tools, and equipment, especially before painting or coating processes.

⚠️ Safety and Handling Information

While Xylene is invaluable, it requires careful handling due to its flammability and potential health effects:

🔺 Personal Protective Equipment (PPE):

- Wear chemical-resistant gloves, goggles, and protective clothing.

- Use only in well-ventilated areas or under fume hoods.

🔥 Fire Safety:

- Keep away from open flames and high heat sources.

- Store in tightly closed containers in a cool, dry, and well-ventilated place.

💧 First Aid Measures:

- Inhalation: Move to fresh air immediately.

- Skin Contact: Wash with soap and water.

- Eye Contact: Rinse cautiously with clean water.

- Ingestion: Seek medical attention—do not induce vomiting.

🌍 Environmental and Health Considerations

Although Xylene is biodegradable under controlled conditions, improper disposal can lead to soil and water contamination. Always follow local environmental regulations when disposing of waste solvents.

Exposure to high concentrations can affect the central nervous system, causing dizziness or headaches—so proper ventilation and PPE use are essential.

💡 Conclusion

Xylene is more than just a solvent—it’s a critical enabler of innovation in paints, coatings, plastics, and adhesives. Its chemical stability, powerful dissolving ability, and controlled evaporation rate make it indispensable in modern industry.

At Amaris Chemical Solutions, we supply high-quality Xylene suitable for industrial, laboratory, and production needs—ensuring reliability, purity, and performance with every drop.

Empower your manufacturing processes with Xylene—the solvent that delivers results.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders