Hytan RS

Whatsapp Order

Hytan RS is a premium reactive silicone-based release agent engineered for efficient mold release, surface protection, and lubrication across diverse industrial sectors. Its unique formulation ensures the formation of a durable, non-stick, thin silicone film that facilitates easy demolding and improves surface finish quality on metals, plastics, rubber, and composite substrates. Its robust performance enhances production efficiency by reducing cycle times and minimizing defects.

Description

Table of Contents

Toggle

Hytan RS

Primary Uses

- Manufacturing & Molding Industry

- Plastic Injection Molding: Provides excellent release for plastic parts, minimizing residue and mold fouling, thus improving cycle time and product quality.

- Rubber Molding: Effective in compression, transfer, and injection molding processes of rubber products to prevent sticking and enhance mold life.

- Composite Molding: Used in fiberglass, carbon fiber, and other composite molding for effortless release and high-quality surface finish.

- Metal Casting & Stamping: Prevents metal parts and tooling from sticking during casting or stamping operations, improving throughput and reducing equipment wear.

- Thermoforming & Vacuum Forming: Facilitates easy separation of thermoformed plastic sheets from molds, reducing defects and improving productivity.

- Surface Protection & Lubrication

- Protective Coatings: Forms temporary, water-resistant protective films on metal, plastic, and painted surfaces to prevent corrosion, oxidation, and contamination during storage or shipping.

- Lubrication: Acts as an anti-friction coating on mechanical parts, sliding surfaces, conveyor belts, and moving components to reduce wear and improve efficiency.

- Anti-blocking Agent: Applied on packaging films and sheets to prevent sticking or blocking during roll handling and processing.

- Automotive Industry

- Assembly Line Use: Releases molded automotive components, such as bumpers, interior panels, and seals, facilitating efficient manufacturing workflows.

- Paint Shop: Prevents adhesive residues and surface defects, aiding in paint application and surface finishing processes.

- Underbody & Engine Components: Used as a lubricant and protective coating for various automotive parts to reduce wear and corrosion.

- Electronics & Electrical Industry

- PCB Manufacturing: Applied as a release and anti-static agent in circuit board production, ensuring defect-free parts and easier handling.

- Cable & Wire Manufacturing: Used to lubricate extrusion dies and molds for smooth release of cables and wires.

Secondary Uses

- Textile Industry

- Used as a softening agent and lubricant in fabric finishing processes to improve fabric hand feel and processing efficiency.

- Acts as an anti-static agent reducing static cling in synthetic fibers.

- Paper Industry

- Applied in paper coating and finishing to improve slip and release properties during rolling and packaging.

- Food Industry

- When formulated with food-grade ingredients, used as a release agent in food packaging and processing machinery (subject to regulatory approvals).

- Marine Industry

- Provides release and anti-fouling properties on molds and surfaces exposed to water-based environments.

- Tool & Equipment Maintenance

- Acts as a protective lubricant for tools, dies, and molds during storage and transport to prevent rust and sticking.

- Construction & Building Materials

- Used in concrete formwork release to facilitate removal of forms without damaging surfaces or leaving residues

KEY PRODUCT FEATURES

1. Basic Identification Attributes

- Chemical Base: Reactive silicone polymer (polydimethylsiloxane derivative)

- Common/Trade Name: Hytan RS

- CAS Number: Proprietary formulation

- HS Code: 3402.19.00

- Synonyms: Silicone Release Agent RS; Reactive Silicone Mold Release

2. Physical & Chemical Properties

- Appearance: Clear to slightly hazy liquid

- Odor: Mild silicone odor

- Solubility: Insoluble in water, soluble in organic solvents

- Flash Point: >100 °C (closed cup)

- Viscosity: Low to medium

- Stability: Chemically stable; forms durable film on curing

3. Safety & Hazard Attributes

- GHS Classification: Low hazard, avoid inhalation of mists

- Toxicity: Low toxicity, non-irritant under normal use

- Exposure Limits: No specific limits, follow good hygiene practices

4. Storage & Handling Attributes

- Store sealed in cool, dry place, away from heat and sunlight

- Shelf Life: 12-24 months

- Use PPE: Gloves, goggles, ventilation

5. Regulatory & Compliance Attributes

- Complies with OSHA, EPA standards

- Suitable for regulated manufacturing environments

6. Environmental & Health Impact

- Biodegradability: Persistent but inert

- Ecotoxicity: Low acute aquatic toxicity

- Bioaccumulation: Not expected

- Carcinogenicity/Mutagenicity: Not classified

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- PPE: Gloves, goggles, dust mask or respirator for mist inhalation

- Avoid prolonged skin contact and inhalation of aerosols

- Use in well-ventilated areas

First Aid Measures

- Inhalation: Fresh air; medical attention if needed

- Skin: Wash with soap and water; medical attention if irritation persists

- Eyes: Rinse 15 min; medical help if irritation continues

- Ingestion: Rinse mouth; seek medical advice if large amounts ingested

Firefighting Measures

- Fire Hazard: Combustible under fire conditions

- Extinguishers: Foam, dry chemical, CO₂, water spray

- Precautions: Protective gear for firefighters

- Decomposition: Carbon and silicon oxides

Related products

Acrytan SN

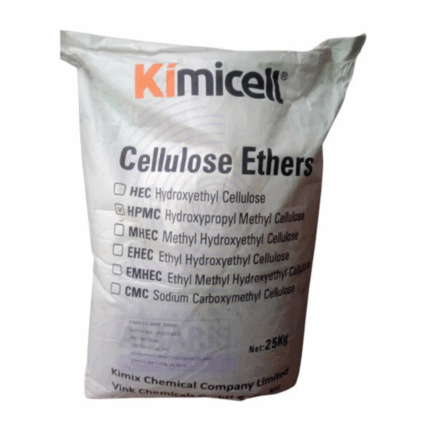

Cellulose Ether

Cellulose ether refers to a group of chemically modified cellulose derivatives where hydroxyl groups on the cellulose backbone are substituted with ether groups such as methyl, hydroxyethyl, or carboxymethyl groups. These modifications improve solubility, viscosity, and film-forming properties while maintaining biodegradability and non-toxicity. Cellulose ethers are white to off-white powders or granules that dissolve in water to form viscous, stable solutions. They are widely used as thickeners, binders, stabilizers, and film formers in industries such as construction, pharmaceuticals, cosmetics, food, and paper.

HPMC Vivapharm E50

HPMC Vivapharm is a high-quality, pharmaceutical-grade hydroxypropyl methylcellulose polymer widely used as an excipient and functional ingredient. It appears as a fine, white to off-white, odorless powder with excellent solubility in cold water and forms clear, viscous solutions. This cellulose ether derivative offers excellent film-forming, thickening, emulsifying, and controlled-release properties. Vivapharm E50 is prized in pharmaceutical, food, and cosmetic industries for its versatility, stability, and safety profile.

Hydroxypropyl Methylcellulose

Hydroxypropyl Methylcellulose HPMC, also known as hypromellose, is a semi-synthetic, non-ionic cellulose ether derived by chemically modifying cellulose through methylation and hydroxypropylation. It is a white to off-white, odorless, tasteless powder that dissolves in cold water to form clear, viscous solutions. HPMC is renowned for its thickening, film-forming, emulsifying, and controlled-release properties. It is widely used in pharmaceuticals, food, cosmetics, construction, and industrial applications due to its safety profile, versatility, and compatibility with various ingredients.

Hylac U94

Hylac is a high-performance, water-based acrylic polymer emulsion widely used as a binding agent and adhesive in coatings, paints, sealants, and construction materials. It offers excellent film formation, adhesion, flexibility, and weather resistance. Hylac U94 is formulated for superior compatibility with a wide range of fillers, pigments, and additives, making it ideal for both industrial and decorative applications. It delivers enhanced durability, water resistance, and color retention, suitable for indoor and outdoor uses.

Hypro

Hypro is a high-quality, non-ionic, water-soluble cellulose ether used primarily as a thickening, suspending, and stabilizing agent. It is derived from cellulose and chemically modified to achieve excellent water retention, rheological control, and film-forming properties. Hypro 88 is widely valued in industries such as construction, paints and coatings, adhesives, pharmaceuticals, and personal care for its ability to enhance texture, improve workability, and stabilize formulations.

Textile Stiffner

Textile Stiffner is a finishing agent formulated to impart stiffness, body, and shape retention to fabrics. It is typically composed of natural or synthetic polymers such as starch derivatives, polyvinyl acetate, acrylic resins, or modified cellulose. Applied during the finishing process, textile stiffeners enhance the handle, drape, and durability of textiles, making them suitable for a wide range of applications from fashion to industrial fabrics.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders