Master Flow

Whatsapp Order

Master Flow is a high-performance concrete plasticizer and superplasticizer designed to improve the workability and flow of concrete mixtures without increasing water content. It enhances concrete slump, making placement and compaction easier, especially in large pours or complex formworks. Master Flow promotes better dispersion of cement particles, leading to improved strength development, reduced bleeding, and increased durability. It is widely used in ready-mix concrete, precast elements, and infrastructure projects to achieve superior surface finish and mechanical properties.

Category: Admixtures

Tags: Construction chemical, MasterFlow, Precision grout, Structural anchoring, Structural grout

Description

Table of Contents

Toggle

Master Flow

Primary Uses

- Concrete Workability Enhancement

Improves flow and slump of concrete mixtures for easier placement and compaction. - Water Reduction

Allows reduction in water content while maintaining workability, leading to higher strength and durability. - High-Performance Concrete

Used in producing high-strength and high-performance concrete for structural and architectural applications.

Secondary Uses

- Self-Leveling Concrete

Facilitates the production of self-leveling or self-compacting concrete mixes. - Precast and Ready-Mix Concrete

Enhances consistency and quality in precast and ready-mix concrete manufacturing. - Shotcrete

Improves pumpability and adhesion in sprayed concrete applications.

KEY PRODUCT FEATURES

1. Basic Identification Attributes

- Chemical Name (IUPAC): Polycarboxylate ether-based superplasticizer (or specific polymeric compound depending on grade)

- Common/Trade Name: Master Flow

- CAS Number: Not applicable (commercial mixture)

- HS Code: 3824.90.00 (Other chemical products and preparations)

- Synonyms: Concrete superplasticizer; concrete plasticizer; polycarboxylate ether (PCE) admixture

2. Physical & Chemical Properties

- Physical State: Liquid

- Color & Odor: Light amber to brown; mild characteristic odor

- pH: Approximately 4–7 (depending on formulation)

- Solubility: Miscible with water

- Density: Approx. 1.05–1.15 g/cm³

- Stability: Stable under recommended storage conditions

3. Safety & Hazard Attributes

- GHS Classification: Not classified as hazardous under normal use

- Toxicity: Low toxicity; avoid prolonged skin contact

- Exposure Limits: No specific occupational limits; use standard industrial hygiene practices

4. Storage & Handling Attributes

- Storage Conditions: Store in cool, dry place away from direct sunlight and freezing temperatures

- Container Type: Supplied in sealed plastic drums or containers

- Shelf Life: Typically 6 to 12 months if stored properly

- Handling Precautions: Use gloves and eye protection; avoid inhalation and prolonged skin contact

5. Regulatory & Compliance Attributes

- Complies with relevant construction chemical regulations and standards

- Free from heavy metals and environmentally harmful substances

6. Environmental & Health Impact

- Biodegradability: Biodegradable under aerobic conditions

- Ecotoxicity: Low aquatic toxicity at recommended dosages

- Bioaccumulation: Not significant

- Carcinogenicity/Mutagenicity: Not classified as hazardous

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- PPE Required: Gloves, safety goggles recommended during handling

- Handling Guidelines: Use in well-ventilated areas; avoid skin and eye contact

- Storage Measures: Keep container tightly closed; avoid freezing and heat exposure

First Aid Measures

- Inhalation: Move to fresh air if irritation occurs

- Skin Contact: Wash thoroughly with soap and water

- Eye Contact: Rinse immediately with plenty of water; seek medical attention if irritation persists

- Ingestion: Rinse mouth; seek medical advice if discomfort occurs

Firefighting Measures

- Fire Hazards: Non-flammable liquid; use caution around electrical equipment

- Extinguishing Media: Use water spray, foam, or dry chemical extinguishers if surrounding materials catch fire

- Special Precautions: Wear protective equipment and self-contained breathing apparatus if necessary

- Hazardous Combustion Products: May emit carbon oxides and other toxic fumes on decomposition

Related products

Aquasol

Aquasol is a water-soluble, high-purity soluble powder typically formulated for use as a mineral supplement or a delivery system in various industries. It often contains vitamins, minerals, or other active ingredients in a readily bioavailable aqueous form. Aquasol products are known for their excellent solubility in water, rapid absorption, and versatility in applications ranging from pharmaceuticals to food fortification and animal nutrition. The exact composition can vary depending on the intended use, but the common trait is its ability to dissolve quickly and evenly in aqueous media.

Calcium Nitrite

Calcium Nitrite is an inorganic compound commonly supplied as a white crystalline powder or granules. It serves primarily as a corrosion inhibitor in reinforced concrete structures, protecting steel reinforcement from rust and prolonging structural lifespan. Calcium nitrite is also used in various industrial processes as an oxidizing agent and preservative. Due to its high solubility in water and strong oxidizing properties, it effectively prevents chloride-induced corrosion and improves concrete durability.

Cellozize Tylose

Cellozize Tylose, commonly known by the trade name Tylose, is a brand of hydroxyethyl cellulose (HEC), a non-ionic, water-soluble cellulose ether derived from natural cellulose. It appears as a white to off-white powder with excellent thickening, binding, and film-forming properties. Tylose is widely used as a rheology modifier, stabilizer, and thickener in various industries including construction, pharmaceuticals, cosmetics, and food. It provides viscosity control, improves texture, and enhances water retention in formulations. Due to its inert, non-toxic, and biodegradable nature, Tylose is favored as a versatile polymer in many applications.

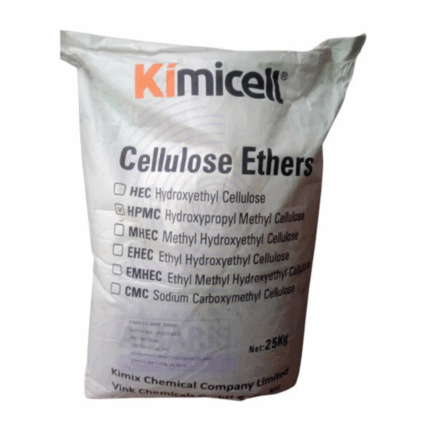

Cellulose Ether

Cellulose ether refers to a group of chemically modified cellulose derivatives where hydroxyl groups on the cellulose backbone are substituted with ether groups such as methyl, hydroxyethyl, or carboxymethyl groups. These modifications improve solubility, viscosity, and film-forming properties while maintaining biodegradability and non-toxicity. Cellulose ethers are white to off-white powders or granules that dissolve in water to form viscous, stable solutions. They are widely used as thickeners, binders, stabilizers, and film formers in industries such as construction, pharmaceuticals, cosmetics, food, and paper.

Fluiden

Fluiden is a specialized high-performance fluid additive commonly used to improve lubrication, reduce friction, and enhance the flow properties of various industrial fluids such as oils, coolants, and hydraulic fluids. It is typically a synthetic or semi-synthetic blend of surfactants, polymers, and corrosion inhibitors designed to optimize fluid stability, performance, and equipment protection. Fluiden products are utilized extensively in automotive, manufacturing, metalworking, and chemical processing industries to prolong machinery life, increase efficiency, and reduce maintenance costs. It appears as a clear to slightly colored liquid with low viscosity and excellent miscibility in water and oils depending on formulation.

Master Cast

Master Cast is a high-quality gypsum-based casting material designed for producing precise and durable molds, prototypes, and decorative castings. It offers excellent flowability, rapid setting time, and high strength after curing. Master Cast is widely used in ceramics, sculpture, dentistry, and industrial mold-making applications where fine detail reproduction and surface smoothness are critical.

Master Cem Is3000

Master Cem IS3000 is a high-performance, advanced polymer-modified cementitious adhesive and bonding agent. It provides superior adhesion, flexibility, and durability for construction and repair applications. This product enhances bonding strength of cement-based materials to substrates like concrete, masonry, tiles, and metals. Suitable for interior and exterior use, it offers excellent resistance to water, weathering, and mechanical stress.

Sodium Gluconate

Sodium Gluconate is a white, crystalline powder derived from gluconic acid and sodium salt. It is highly water-soluble, biodegradable, and non-toxic, widely used as a chelating agent, sequestrant, and buffering agent across various industries. Sodium Gluconate is favored for its excellent ability to bind metal ions, improve cleaning efficiency, and stabilize formulations. It finds extensive applications in construction, water treatment, food, pharmaceuticals, cosmetics, and textiles.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders