Acid Oil Soya

Whatsapp Order

Acid Oil Soya is a byproduct derived from the refining of soybean oil. It is a dark-colored, free fatty acid-rich liquid containing mainly oleic and linoleic acids. Acid Oil Soya is commonly used in industrial applications such as soap making, animal feed, and as a raw material in the production of biodiesel, lubricants, and other chemicals.

Description

Table of Contents

Toggle

Acid Oil Soya

Primary Uses

- Biodiesel Production

- Used as a low-cost feedstock for biodiesel manufacturing due to its high free fatty acid (FFA) content.

- Processed via esterification/transesterification to produce fatty acid methyl esters (FAME).

- Animal Feed Supplement

- Mixed with feed pellets as an energy source for livestock (poultry, cattle, pigs).

- Provides fatty acids for improved animal growth and coat condition.

- Soap & Oleochemical Industry

- Raw material for low-grade soaps and fatty acid distillation.

- Used in lubricants, greases, and industrial surfactants.

Secondary Uses

- Agriculture

- Acts as a dust suppressant in feed mills.

- Used in organic pesticides as a carrier oil.

- Wastewater Treatment

- Helps in flotation processes to remove oil/grease from industrial effluents.

- Rubber & Plastics

- Softening agent in rubber recycling.

KEY PRODUCT FEATURES

1. Basic Identification Attributes

- Chemical Name: Hydrolyzed Soybean Oil Fatty Acids

- Common/Trade Names:

- Soya Acid Oil

- Soybean Acid Oil

- Hydrolyzed Soy Oil

- CAS Number: 68308-53-2 (for soybean acid oil)

- HS Code: 1518.00.90 (vegetable oil acid oils)

- Molecular Formula: Variable (mixture of C16-C18 fatty acids)

- Synonyms:

- Soybean fatty acid distillate

- Acidulated soybean soapstock

- Soy oil fatty acids

2. Physical & Chemical Properties

- Physical State: Viscous liquid to semi-solid

- Color & Odor: Dark brown to black; characteristic fatty odor

- Melting Point: 20-30°C (depends on composition)

- Boiling Point: >300°C (decomposes)

- Density: 0.90-0.95 g/cm³ at 20°C

- Solubility:

- Water: Insoluble

- Organic solvents: Soluble in ethanol, ether, chloroform

- pH Level: 2-5 (acidic)

- Vapor Pressure: Negligible at 20°C

- Flash Point: >150°C (COC)

- Viscosity: 50-100 cP at 40°C

3. Safety & Hazard Attributes

- Hazard Class (GHS):

- Skin Irritation (Category 2)

- Eye Irritation (Category 2)

- NFPA Ratings:

- Health: 1

- Flammability: 1

- Reactivity: 0

- Exposure Limits:

- No specific OEL established

- General dust limit: 10 mg/m³ (total), 5 mg/m³ (respirable)

- Reactivity:

- Incompatible with strong oxidizers

- Corrosive to some metals

4. Storage & Handling Attributes

- Storage Conditions:

- Store at 15-40°C

- Keep containers tightly closed

- Protect from moisture

- Incompatible Materials:

- Strong bases

- Strong oxidizers

- Container Type:

- Carbon steel or stainless steel drums

- HDPE containers for small quantities

- Shelf Life: 12-24 months if properly stored

- Special Handling:

- Use chemical-resistant gloves (nitrile)

- Eye protection recommended

- Adequate ventilation

5. Regulatory & Compliance Attributes

- Regulatory Status:

- FDA: 21 CFR 172.860 (as fatty acids)

- EU: Approved as food additive E570

- REACH: Registered

- Hazard Symbols (GHS):

- Exclamation mark (irritant)

- Transportation Restrictions:

- Not classified as dangerous goods

- Waste Disposal Method:

- Incineration or recycling preferred

- Not RCRA hazardous

6. Environmental & Health Impact

- Ecotoxicity:

- LC50 (fish): >100 mg/L

- EC50 (daphnia): >100 mg/L

- Persistence in Environment:

- Readily biodegradable (>60% in 28 days)

- Carcinogenicity/Mutagenicity:

- Not classified (IARC, NTP, OSHA)

- Biodegradability:

- 90% in 28 days (OECD 301F)

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

Personal Protective Equipment (PPE):

- Gloves: Nitrile or neoprene (for chemical resistance)

- Eye Protection: Safety goggles + face shield (for splash risk)

- Respiratory: N95 mask (when handling heated material)

- Body: Chemical-resistant apron + steel-toe boots

Handling & Storage:

- Store in stainless steel or HDPE containers

- Keep away from oxidizers and strong acids

- Maintain temperature below 50°C (to prevent decomposition)

- Use grounded equipment to prevent static discharge

Hygiene Measures:

- No eating/drinking in handling areas

- Wash hands thoroughly after handling

- Provide emergency eyewash station nearby

First Aid Measures

Skin Contact:

- Remove contaminated clothing

- Wash with mild soap and warm water for 15 minutes

- Apply emollient cream if irritation occurs

Eye Contact:

- Flush with lukewarm water for 15-20 minutes

- Seek medical attention if irritation persists

Ingestion:

- Rinse mouth with water

- Do NOT induce vomiting

- Seek medical advice if large amounts swallowed

Inhalation:

- Move to fresh air

- Give oxygen if breathing is difficult

Firefighting Measures

Fire Characteristics:

- Combustible liquid (flash point typically >150°C)

- Burns with thick, black smoke

- May release acrolein at high temperatures

Extinguishing Media:

- Dry chemical powder

- CO₂

- Foam

- Water spray (to cool containers)

Special Precautions:

- Wear SCBA (self-contained breathing apparatus)

- Contain runoff to prevent environmental contamination

- Cool adjacent containers with water spray

Spill Management

Small Spills:

- Contain with absorbent materials (vermiculite, sand)

- Collect in approved waste containers

Large Spills:

- Implement secondary containment

- Use oil spill booms for liquid containment

- Prevent entry into drains or watercourses

Storage & Disposal

Storage Conditions:

- Keep in cool, well-ventilated area

- Away from ignition sources

- In corrosion-resistant containers

Disposal:

- Treat as industrial waste

- Follow local waste oil regulations

- Consider recycling/reprocessing options

Related products

Amprolium Hydrochloride

Amprolium Hydrochloride is a white, odorless, crystalline powder used primarily as a coccidiostat, which means it inhibits the growth of Eimeria species (protozoan parasites) responsible for coccidiosis in poultry and other animals. It works by mimicking thiamine (vitamin B1), thereby competitively inhibiting thiamine uptake by the parasite, disrupting its metabolism, and preventing its proliferation. Amprolium HCl is widely used in veterinary medicine, especially in poultry farming, and is often included in feed or drinking water. It complies with BP 2008 and USP 32 pharmacopeial standards.

Camelina

Camelina (Camelina sativa), also known as false flax or gold-of-pleasure, is an ancient oilseed crop belonging to the Brassicaceae family. It produces small, golden-brown seeds that are rich in oil content, typically around 30-40%. The oil extracted from Camelina seeds is prized for its high content of omega-3 fatty acids, antioxidants, and bioactive compounds, making it valuable in food, feed, cosmetic, and industrial applications. Camelina oil has a mild, nutty flavor and a favorable fatty acid profile including linolenic acid, making it a sustainable alternative to traditional vegetable oils. The crop is noted for its short growing season, low input requirements, and adaptability to marginal soils and climates.

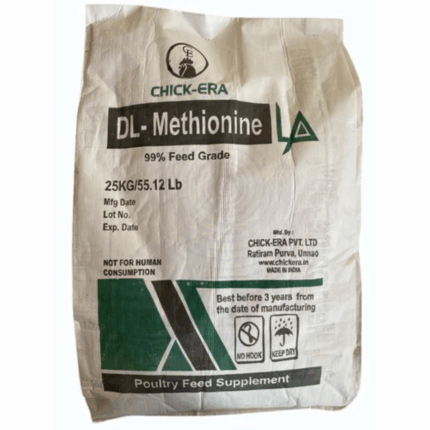

DL-Methionine Feed Grade

DL-Methionine Feed Grade is a synthetic, racemic mixture of the amino acid methionine, consisting of equal parts D- and L-isomers. It is an essential sulfur-containing amino acid widely used as a nutritional supplement in animal feed formulations. DL-Methionine plays a critical role in protein synthesis, growth, and metabolic functions in livestock and poultry. This feed-grade quality ensures high purity (minimum 99%) and suitability for inclusion in feed blends to enhance growth performance, improve feed efficiency, and prevent methionine deficiency-related disorders.

Magnesium Oxide

Magnesium Oxide (MgO) is a white, odorless, alkaline earth metal oxide powder. It is produced by calcining magnesium carbonate or hydroxide at high temperatures, resulting in a fine, white powder with a high melting point. Magnesium Oxide is widely used for its refractory properties, chemical stability, and ability to neutralize acids. It serves important roles in pharmaceuticals, agriculture, environmental applications, and various industrial processes.

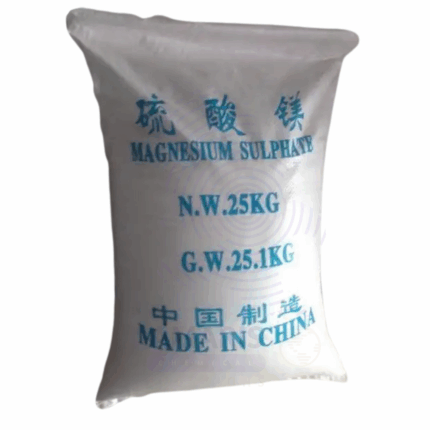

Magnesium Sulphate (Epsom Salt)

Magnesium Sulphate Epsom Salt, commonly known as Epsom Salt, is an inorganic salt composed of magnesium, sulfur, and oxygen with the formula MgSO₄. It typically appears as colorless or white crystalline granules and is highly soluble in water. In its heptahydrate form (MgSO₄·7H₂O), it is widely used in agriculture, pharmaceuticals, food, and industrial applications. Epsom Salt is valued for its muscle relaxant, laxative, and magnesium supplementation properties, as well as for its role in improving soil fertility and plant growth.

Manganese Sulphate Monohydrate

Manganese Sulphate Monohydrate is an inorganic chemical compound with the formula MnSO₄·H₂O. It appears as a pale pink crystalline powder and is highly soluble in water. It is primarily used as a source of manganese, an essential micronutrient, in fertilizers, animal feed, and industrial processes. This monohydrate form is the most stable and commonly used in agriculture and feed-grade applications. It also finds use in various chemical syntheses, electroplating, and as a reagent in laboratories.

Salinomycin Granular Feed Grade

Salinomycin Granular Feed Grade is an ionophore antibiotic widely used as a coccidiostat in poultry and livestock feed. It helps control and prevent coccidiosis, a parasitic disease affecting the intestinal tract of animals, thereby improving growth performance and feed efficiency. This granular formulation ensures uniform mixing in feed and stable dosage delivery.

Sodium Selenite

Sodium Selenite is an inorganic selenium compound with the formula Na₂SeO₃. In its commercial 45% concentration, it is typically supplied as a colorless to slightly yellow aqueous solution or as a crystalline solid with 45% selenium content. It is primarily used as a micronutrient additive in animal nutrition, a reagent in the pharmaceutical and glass industries, and in various research applications. Highly bioavailable, it serves as a key selenium source where controlled selenium supplementation is critical. This 25kg product offers precise dosing, stability, and ease of handling in industrial and agricultural settings.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders