Bell in Vacuum

$ 40.02 Original price was: $ 40.02.$ 30.96Current price is: $ 30.96.

Aluminum hydroxide

$ 1.89 Original price was: $ 1.89.$ 1.78Current price is: $ 1.78.

Bell in Vacuum with Air Pump with Plate

$ 49.03 Original price was: $ 49.03.$ 48.99Current price is: $ 48.99.

Whatsapp Order

Bell in Vacuum with Air Pump with Plate is an integrated vacuum apparatus used to create and maintain low-pressure environments for laboratory and industrial applications. This assembly includes a vacuum bell, an air pump to evacuate air from the chamber, and a sturdy plate to support or seal samples or components during vacuum processes. Designed for durability and reliability, it is widely used in experiments requiring controlled atmospheric pressure, including vacuum filtration, drying, and physical science demonstrations.

Description

Table of Contents

Toggle

Bell in Vacuum with Air Pump with Plate

Primary Uses

- Laboratory Applications

- Utilized for vacuum filtration and drying of chemical or biological samples.

- Used in physics and chemistry labs for creating low-pressure environments for experiments.

- Supports vacuum distillation and degassing procedures.

- Employed in educational demonstrations to illustrate vacuum principles and air pressure effects.

Secondary Uses

- Industrial Applications

- Applied in vacuum packaging systems for small-scale sample preparation.

- Used in quality control processes involving vacuum drying and material testing.

- Supports maintenance and calibration of vacuum pumps and related equipment.

- Employed in prototype manufacturing processes that require controlled atmospheric conditions.

PRODUCT KEY FEATURES

1.Basic Identification Attributes

- Component Type: Vacuum Bell Assembly with Air Pump and Plate

- Material: Stainless steel, glass, rubber seals, and durable plastics for pump components

- Function: Creates and maintains vacuum by air evacuation, supports sample containment

2.Physical & Chemical Properties

- Pressure Resistance: Designed to maintain vacuum with external atmospheric pressure

- Pump Capacity: Suitable for laboratory-scale vacuum applications

- Durability: Resistant to corrosion and wear from repeated use

3.Safety & Hazard Attributes

- Mechanical Risks: Potential implosion if vacuum is compromised; use with caution

- Noise: Air pump may produce operational noise

- Toxicity: Non-toxic materials used

4.Storage & Handling Attributes

- Storage Conditions: Keep in clean, dry environment away from heavy impacts

- Handling Precautions: Handle glass components carefully; avoid sudden pressure changes

5.Regulatory & Compliance Attributes

- Manufactured according to industry standards for vacuum equipment

- Quality assurance for reliable vacuum maintenance

6.Environmental & Health Impact

- Components recyclable according to material types

- Minimal environmental footprint when disposed properly

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- Use protective gloves and eyewear when handling to prevent injury

- Avoid rapid vacuum release to prevent damage or injury

First Aid Measures

- For injuries due to breakage, clean and disinfect wounds; seek medical attention if severe

- No chemical exposure risk

Firefighting Measures

- Fire Hazard: Non-flammable

- Extinguishing Media: Not applicable

Related products

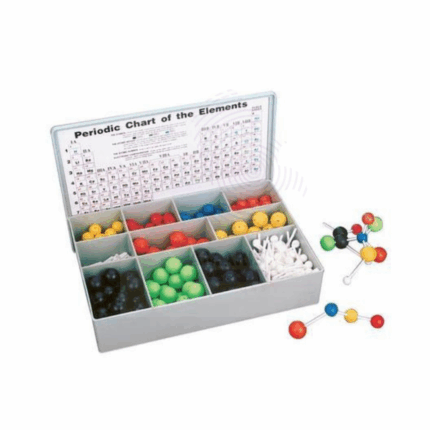

Atomic Model Set

The Atomic Model Set is an educational tool designed to visually demonstrate the structure of atoms and molecules. It consists of color-coded balls representing protons, neutrons, and electrons, connected by rods to simulate atomic bonds. This set is widely used in classrooms, laboratories, and training centers to aid in the teaching of atomic theory, molecular geometry, chemical bonding, and related concepts. Made from durable plastic materials, the set provides a hands-on, interactive experience that enhances understanding of complex scientific principles.

Boyle’s Law Apparatus

Boyle’s Law Apparatus is a precision laboratory instrument designed to demonstrate and verify Boyle’s Law, which states that the pressure of a given mass of gas is inversely proportional to its volume at constant temperature. The apparatus typically consists of a sealed cylinder with a movable piston or syringe, pressure gauge, and volume scale, allowing students and researchers to observe and measure the relationship between pressure and volume in gases. It is widely used in educational and research laboratories to teach fundamental gas laws and perform experimental validation of theoretical principles.

Centre of Gravity apparatus

The Centre of Gravity Apparatus is a precision instrument designed to demonstrate and measure the center of gravity of various objects. It consists of a rigid frame, adjustable clamps, and pointers that help identify the balance point of irregular shapes and composite bodies. Widely used in physics laboratories and industrial training, this apparatus aids in understanding the principles of equilibrium, stability, and moments. Its sturdy construction ensures accurate and repeatable measurements essential for educational and quality control purposes.

complete kymograph equipment

Complete Kymograph Equipment is a precision instrument used primarily in physiology and biological research to record changes in pressure, motion, or other physiological phenomena over time. It consists of a rotating drum wrapped with a recording paper and various attachments such as levers, pens, and sensors to capture mechanical movements or biological signals. This equipment is essential for experiments involving muscle contractions, blood pressure measurements, and other dynamic biological processes.

Contact key

Product Description

The Contact Key is a fundamental switching device used in electrical circuits to manually open or close the flow of current. Commonly used in physics laboratories for demonstration and experimentation with circuits, it enables controlled activation of current for brief or sustained durations. Made from durable, conductive metals with insulating bases, Contact Keys are essential components in circuit testing, timing devices, and low-voltage experimental setups.

Demonstration transformer

The Demonstration Transformer is an educational and laboratory device designed to illustrate the principles of electromagnetic induction, voltage transformation, and mutual inductance. Typically composed of a laminated iron core with interchangeable primary and secondary coils, it allows for hands-on experiments involving step-up and step-down voltage transformation. Ideal for both laboratory demonstrations and industrial training settings, it supports a range of voltage and current inputs and can safely demonstrate real-time transformer behavior using AC power sources.

Dissecting Forceps

Dissecting Forceps are precision hand tools designed for grasping, holding, and manipulating tissues or small objects during dissection or surgical procedures. Typically made from high-quality stainless steel or surgical-grade metal, these forceps offer durability, corrosion resistance, and ease of sterilization. They come in various shapes and sizes, including straight or curved tips, serrated or smooth jaws, to suit different dissection needs in medical, veterinary, biological research, and educational settings. Their ergonomic design allows fine control and minimizes tissue damage during delicate operations.

Dissecting scissors

Dissecting Pan with Wax is a specialized laboratory tool consisting of a shallow metal or plastic pan filled with a layer of soft, moldable wax used to securely position biological specimens during dissection. The wax surface allows specimens to be pinned or stabilized without damage, providing a firm and adjustable platform for precise anatomical work. This setup is commonly used in medical, veterinary, and educational laboratories to facilitate detailed examination, surgical practice, and teaching demonstrations. The pan is typically durable, easy to clean, and compatible with standard dissection instruments.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders