Diethyl Phthalate

Whatsapp Order

Diethyl Phthalate is a high-purity, colorless, oily liquid with a faint, sweet aromatic odor. With a minimum of 99% active content, DEP 99% is a trusted solvent and plasticizer that offers excellent stability, low volatility, and high compatibility with a wide range of organic and polymeric materials. It is widely used in the cosmetic, pharmaceutical, plastics, coatings, and fragrance industries where purity is critical for both performance and safety. Its mild toxicological profile and solvency characteristics make it a versatile component in numerous sensitive and industrial applications.

Description

Table of Contents

Toggle

Diethyl Phthalate

Primary Uses

- Plasticizer for Polymers and Resins

- Used as a primary plasticizer for cellulose acetate, cellulose nitrate, and polyvinyl acetate to impart flexibility and durability.

- Enhances elasticity and clarity in molded goods, films, and coatings.

- Offers good plasticization for PVC in non-critical applications where clarity and low volatility are needed.

- Fragrance and Cosmetic Applications

- Functions as a fixative in perfumes and body sprays to slow down evaporation and extend fragrance retention.

- Acts as a carrier solvent for essential oils and aroma chemicals in formulations requiring purity and inertness.

- Used in deodorants, lotions, and hair care products where solubility and mildness are necessary.

- Pharmaceutical and Topical Products

- Employed as a solvent and carrier in topical pharmaceutical preparations such as ointments, gels, and creams.

- Used in transdermal delivery systems to enhance active ingredient dispersion and penetration.

- Suitable for formulations requiring low reactivity and high purity.

- Solvent for Industrial and Chemical Formulations

- Serves as a high-purity solvent in dyes, resins, and inks where slow evaporation and solvency are critical.

- Applied in the manufacture of surface coatings, printing inks, and polishes to improve workability and film formation.

- Used in adhesives and sealants for its compatibility and softening properties.

- Paints, Coatings, and Finishes

- Enhances flow, spreadability, and gloss in lacquer and coating systems.

- Improves flexibility and prevents cracking in cured paint films.

- Serves as a coalescing agent in specialty coatings.

Secondary Uses

- Insect Repellents and Pesticide Carriers

- Acts as an effective solvent and dispersing agent in mosquito repellent formulations.

- Used in agriculture and public health products requiring controlled evaporation and safety on skin contact.

- Personal Care and Hygiene Products

- Incorporated in nail polishes, removers, and bath oils for its solvency and spreadability.

- Used in aftershaves and cleansing creams as a mild and non-reactive carrier.

- Textile and Leather Industry

- Functions as a softener and lubricant in textile processing.

- Used in leather finishing formulations to impart flexibility and smooth texture.

- Laboratory and Analytical Use

- Used as a high-purity solvent in analytical chemistry and research.

- Applied in the extraction and purification of organic compounds.

- Electronics and Optical Industry

- Serves as a cleaning and processing solvent for electronic components where low residue is essential.

- Applied in specialty optical formulations and lens coatings.

- Plastic Film and Packaging

- Used in the production of flexible plastic films and sheets, especially those requiring transparency and stability.

- Improves processing behavior and flexibility in food-safe and cosmetic packaging.

KEY PRODUCT FEATURES

1. Basic Identification Attributes

- Chemical Name (IUPAC): Diethyl benzene-1,2-dicarboxylate

- Common/Trade Name: Diethyl Phthalate 99%, DEP 99%

- CAS Number: 84-66-2

- HS Code: 2917.39.00

- Molecular Formula: C₁₂H₁₄O₄

- Synonyms:

- Diethyl Phthalate

- DEP

- Ethyl phthalate Phthalic acid diethyl ester

2. Physical & Chemical Properties

- Physical State: Clear, colorless oily liquid

- Odor: Faint, sweet aromatic odor

- Purity: ≥ 99%

- Boiling Point: Approx. 295°C

- Melting Point: -4°C

- Density: ~1.12 g/cm³ at 20°C

- Solubility: Slightly soluble in water; fully miscible with alcohols, ethers, and most organic solvents

- Vapor Pressure: Very low at room temperature

- Stability: Chemically stable under standard conditions; avoid oxidizing agents

3. Safety & Hazard Attributes

- Hazard Class (GHS): Not classified as hazardous under GHS; may cause mild skin and eye irritation

- Toxicity:

- Oral LD₅₀ (rat): ~8,600 mg/kg

- Dermal LD₅₀ (rabbit): >10,000 mg/kg

- Exposure Limits:

- OSHA PEL: Not established

- ACGIH TLV: TWA = 5 mg/m³ (inhalable fraction)

- Flammability: Combustible liquid; flash point ~161°C

4. Storage & Handling Attributes

- Storage Conditions: Store in tightly sealed containers in a cool, dry, well-ventilated area

- Container Type: HDPE drums, steel barrels, or lined IBCs

- Shelf Life: 2–3 years under proper storage conditions

- Handling Precautions: Avoid direct contact; use appropriate protective equipment and ensure proper ventilation

5. Regulatory & Compliance Attributes

- REACH registered and compliant

- Listed in major global chemical inventories (TSCA, EINECS, DSL, AICS, ENCS, PICCS)

- Acceptable for use in cosmetic and pharmaceutical applications in accordance with regulatory guidelines

- Manufactured in compliance with GMP for non-active ingredients when required

6. Environmental & Health Impact

- Ecotoxicity: Moderately toxic to aquatic organisms

- Persistence: Readily biodegradable under aerobic conditions

- Bioaccumulation: Low to moderate (log Kow ~2.4)

- Carcinogenicity/Mutagenicity: Not classified as carcinogenic or mutagenic under current classifications

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

PPE Required:

- Chemical-resistant gloves (nitrile or neoprene)

- Safety goggles or face shield

- Protective clothing (lab coat or chemical apron)

- Respiratory protection in poorly ventilated environments

Handling Guidelines:

- Avoid inhalation of vapors and skin/eye contact

- Use in well-ventilated areas or under fume hoods

- Prevent spillage and environmental release

- Keep away from heat, open flames, and oxidizing materials

Storage Measures:

- Store in tightly closed containers in a cool, dry place

- Protect from moisture, direct sunlight, and static discharge

- Keep separate from incompatible materials like strong oxidizers and acids

Hygiene Practices:

- Wash hands thoroughly after handling

- Do not eat, drink, or smoke while handling the product

- Maintain clean work areas and follow routine decontamination procedures

First Aid Measures

- Inhalation: Move affected person to fresh air. Seek medical attention if symptoms persist.

- Skin Contact: Wash thoroughly with soap and water. Seek medical advice if irritation develops.

- Eye Contact: Rinse with clean water for at least 15 minutes. Get immediate medical attention.

- Ingestion: Rinse mouth; do not induce vomiting. Seek emergency medical attention immediately.

Firefighting Measures

- Fire Hazards: Combustible liquid; may emit toxic fumes (CO, CO₂) when burned

- Extinguishing Media: Use foam, dry chemical, or carbon dioxide

- Special Precautions: Firefighters should wear full protective gear and self-contained breathing apparatus

- Decomposition Products: Carbon monoxide, carbon dioxide, and possibly phthalic acid derivatives

Related products

Desgel HG (Carbomer)

Desgel HG is a high-purity Carbomer-based thickening agent, widely used in pharmaceutical, cosmetic, and personal care formulations. It is a cross-linked polyacrylic acid polymer, neutralized to form high-viscosity gels with excellent clarity and stability. Desgel HG is prized for its thickening, suspending, emulsifying, and stabilizing capabilities, especially in aqueous and hydroalcoholic systems. It is highly efficient at low concentrations and compatible with a wide pH range (when neutralized). This makes it ideal for use in gels, creams, lotions, hand sanitizers, topical formulations, and other semi-solid systems.

Di Acetone Alcohol

Di Acetone Alcohol (chemical name: 4-Hydroxy-4-methylpentan-2-one) is a clear, colorless to pale yellow liquid with a mild acetone-like odor. It is a versatile organic solvent and intermediate widely used in the manufacture of coatings, adhesives, inks, and specialty chemicals. Di Acetone Alcohol exhibits excellent solvency for resins, oils, and fats, combined with moderate evaporation rate and low volatility compared to acetone, making it suitable for controlled drying applications. It also serves as a chemical intermediate in synthesis reactions and as a component in solvent blends to optimize performance and drying characteristics.

Dibutyl Phthalate

Dibutyl Phthalate (DBP) is a colorless, oily liquid with a faint aromatic odor, belonging to the phthalate ester family. It is primarily used as a plasticizer to impart flexibility, durability, and softness to rigid polymers like polyvinyl chloride (PVC). DBP is valued for its excellent compatibility with polymers, good plasticizing efficiency, low volatility, and resistance to extraction by water and oils. Besides plastics, DBP is utilized in coatings, adhesives, printing inks, cosmetics, and other industrial applications. Its moderate cost and versatile performance make it a key chemical in various manufacturing sectors.

Diethyl Glycol

Diethyl Glycol is a clear, colorless, hygroscopic, and viscous liquid with a mild odor. It is a diol with two hydroxyl groups, making it a versatile chemical intermediate and solvent. DEG is miscible with water, alcohols, and many organic solvents. It is widely used in the manufacture of plasticizers, solvents, resins, and as an intermediate in chemical syntheses. Due to its high boiling point and solvent properties, DEG finds broad applications across industrial, pharmaceutical, and cosmetic sectors.

Dimethicone Silicon Oil

Dimethicone Silicon Oil, also known as polydimethylsiloxane (PDMS) or silicone oil, is a clear, odorless, and non-volatile silicone-based polymer widely used for its lubricating, anti-foaming, water-repellent, and skin-conditioning properties. It is a linear silicone polymer composed of repeating dimethylsiloxane units. Dimethicone exhibits excellent thermal stability, chemical inertness, and low surface tension, making it highly versatile in pharmaceutical, cosmetic, personal care, industrial, and food applications. It is available in various viscosities, from very low to high viscosity oils, enabling tailored formulations.

Dimethyl Acetimide

Dimethyl Acetimide is a versatile organic compound used predominantly as a solvent and intermediate in chemical syntheses. It is a colorless to pale yellow liquid with good solvency properties for a wide range of organic substances. Known for its stability and relatively low toxicity compared to similar amides, Dimethyl Acetimide finds applications in pharmaceuticals, agrochemicals, and specialty chemical manufacturing. Its miscibility with water and many organic solvents makes it suitable for formulation and processing roles.

Dioctyl Phthalate

Dioctyl Phthalate (DOP), also known as di(2-ethylhexyl) phthalate (DEHP), is a widely used plasticizer primarily added to polyvinyl chloride (PVC) and other polymers to enhance flexibility, durability, and workability. It is a clear, colorless, oily liquid with a slight ester odor. Due to its excellent compatibility with many polymers and long-lasting plasticizing effects, DOP is one of the most common phthalate plasticizers used in industries such as construction, automotive, packaging, and medical devices. It also serves as a solvent and dispersant in various chemical processes.

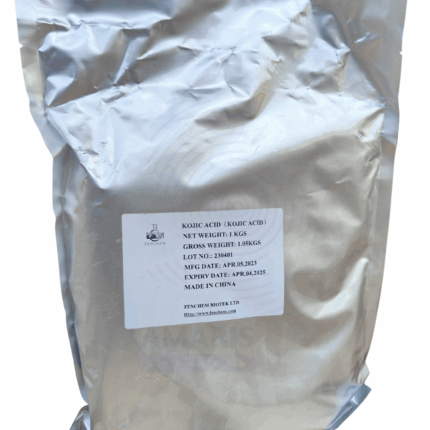

Kojic Acid

Kojic Acid is a naturally derived organic compound produced by certain species of fungi, commonly Aspergillus and Penicillium. It appears as a white to light yellow crystalline powder with a slightly acidic taste and is highly soluble in water and alcohol. Kojic Acid is primarily used in the cosmetic and pharmaceutical industries for its skin-lightening and antioxidant properties. It inhibits melanin production by blocking the enzyme tyrosinase, making it a key ingredient in formulations aimed at reducing hyperpigmentation, age spots, and uneven skin tone.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders