HDPE Film F52H04

Whatsapp Order

HDPE Film F52H04 Opalene is a high-density polyethylene film grade resin specially engineered for producing thin, flexible, and high-strength films. It is designed for blown film extrusion processes, delivering excellent mechanical properties, superior clarity (opal/opalene finish), and consistent gauge control. This resin offers high tensile strength, good puncture resistance, and excellent moisture barrier properties, making it ideal for packaging applications requiring durability and flexibility. Its balanced processing characteristics enable fast extrusion rates and uniform film thickness.

Description

Table of Contents

Toggle

HDPE Film F52H04 (Opalene)

Primary Uses

- Packaging Industry

- Used extensively in flexible packaging films for food products such as snack wrappers, frozen food bags, and fresh produce packaging.

- Suitable for shopping bags, carrier bags, and refuse sacks requiring high tear resistance and durability.

- Employed in shrink films and stretch wraps for palletizing and bundling products.

- Used in industrial packaging films for protection and moisture barrier in storage and transport.

- Agricultural Films

- Production of mulch films and greenhouse covers providing protection while allowing light diffusion (opal finish).

- Used in silage films for forage preservation due to moisture and oxygen barrier properties.

- Medical and Hygiene Products

- Used in protective covers, medical packaging films, and hygiene product wraps where sterility and barrier protection are essential.

- Consumer Goods

- Production of garbage bags, liners, and protective films for household and commercial use.

- Used in laminated films for flexible packaging combining mechanical strength and printability.

Secondary Uses

- Industrial Applications

- Films for industrial liners and protective sheets in construction and manufacturing.

- Used as vapor barriers in building insulation and packaging.

- Printing & Lamination

- Acts as a substrate for lamination with other polymers or paper to enhance packaging aesthetics and performance.

- Recycling Applications

- Accepted in film recycling streams and can be reprocessed into various low-to-medium-end film products.

KEY PRODUCT FEATURES

1. Basic Identification Attributes

- Chemical Name (IUPAC): Polyethylene, high-density (HDPE)

- Common/Trade Name: HDPE Film F52H04, Opalene

- CAS Number: 9002-88-4

- HS Code: 3920.20.00

- Polymer Type: High-density polyethylene (HDPE) film grade

- Synonyms: Opalene HDPE film resin; HDPE blown film resin

2. Physical & Chemical Properties

- Physical State: Pellet resin for film extrusion

- Color & Odor: Natural/opalescent; odorless

- Density: ~0.945 g/cm³

- Melt Flow Index (MFI): Approximately 0.20–0.40 g/10 min

- Melting Point: Approx. 130°C

- Tensile Strength: High tensile strength suitable for thin film applications

- Elongation at Break: High, providing flexibility

- Moisture Barrier: Excellent moisture resistance

- Optical Properties: Opal/opalene finish providing light diffusion and moderate clarity

- Environmental Stress Crack Resistance: Good

3. Safety & Hazard Attributes

- GHS Classification: Not hazardous

- Toxicity: Non-toxic, suitable for food contact applications (subject to certification)

- Handling: Non-irritant under normal handling

4. Storage & Handling Attributes

- Container Type: Supplied in bags or bulk packaging

- Storage Conditions: Dry, cool environment away from direct sunlight and moisture

- Shelf Life: 2–3 years if stored properly

- Handling Notes: Minimize dust; use appropriate PPE if dust generation occurs

5. Regulatory & Compliance Attributes

- Food contact approved by FDA, EFSA (subject to certification)

- Complies with EU Regulation No. 10/2011 for plastic materials in contact with food

- REACH and RoHS compliant

6. Environmental & Health Impact

- Biodegradability: Non-biodegradable but recyclable

- Recycling: Accepted in polyethylene film recycling streams

- Ecotoxicity: Low, inert polymer

- Carcinogenicity/Mutagenicity: Not classified

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- PPE Required: Gloves, safety goggles, dust masks when handling powder or resin pellets

- Handling Guidelines: Use in well-ventilated areas; avoid dust inhalation

- Hygiene Practices: Wash hands after handling; avoid ingestion and eye contact

First Aid Measures

- Inhalation: Move to fresh air if irritation occurs

- Skin Contact: Wash with soap and water

- Eye Contact: Rinse with water for at least 15 minutes; seek medical advice if irritation persists

- Ingestion: Not harmful in small amounts; seek medical advice if large quantities swallowed

Firefighting Measures

- Fire Hazards: Combustible solid; emits dense smoke when burned

- Extinguishing Media: Water spray, foam, dry chemical, CO₂

- Combustion Products: Carbon monoxide, carbon dioxide, hydrocarbons

- Firefighter PPE: Use self-contained breathing apparatus and protective gear

Related products

HDPE Injection HMA035/3255

HDPE Injection HMA035/3255 is a high-density polyethylene resin specially formulated for injection molding processes. This grade exhibits excellent flow characteristics with moderate melt flow index optimized for producing precise, high-strength molded parts with superior surface finish. It combines good impact resistance, stiffness, and chemical resistance with excellent dimensional stability. The resin ensures reliable processing performance across a broad temperature range and is suitable for complex, detailed, or large injection-molded components. It is supplied as uniform granules designed for smooth melting and consistent molding cycles.

HDPE pipe HS CRP 100- PE 100 (black water pipe)

HDPE pipe HS CRP 100- PE 100 (black water pipe) is a high-density polyethylene (HDPE) pipe grade resin specially designed for the manufacture of high-performance pressure pipes. This grade corresponds to PE 100 classification, meaning it has enhanced strength and durability characteristics suitable for high-pressure applications. The resin exhibits excellent resistance to slow crack growth, outstanding chemical resistance, and superior impact strength even at low temperatures. HDPE PE 100 pipe is widely used in demanding infrastructure, water supply, gas distribution, and industrial piping systems due to its long service life, flexibility, and corrosion resistance.

Natural rubber

Natural Rubber is an elastomer harvested from the latex sap of rubber trees (Hevea brasiliensis). It is a highly elastic, resilient, and durable polymer used globally in numerous industries. Natural Rubber is prized for its excellent tensile strength, flexibility, abrasion resistance, and ability to withstand deformation. It is widely utilized in manufacturing tires, industrial goods, footwear, and medical devices. The product is available in various forms such as sheets, blocks, crepes, and latex concentrate.

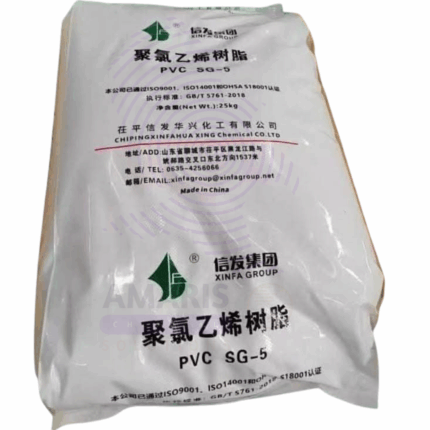

Polyvinyl Chloride Resin

Polyvinyl Chloride Resin is a white, odorless powder widely used as the base material in the production of both rigid and flexible PVC products. It is produced by polymerizing vinyl chloride monomer (VCM) and is categorized by K-value, which defines molecular weight and processing characteristics. PVC resin is valued for its durability, chemical resistance, electrical insulation, and flame retardancy. It is one of the most versatile plastics used across multiple industries including construction, electrical, automotive, packaging, and healthcare.

Polyvinyl Chloride Resin 701

Polyvinyl Chloride Resin 701 is a high-quality suspension-grade polyvinyl chloride resin with a K-value of approximately 70–71, indicating high molecular weight. It is widely used in the production of flexible PVC products where excellent strength, elongation, and plasticizer absorption are required. PVC Resin 701 offers superior mechanical properties, high thermal stability, and good compatibility with plasticizers, making it suitable for calendaring, extrusion, and molding applications in diverse industries.

Polyvinyl Chloride Resin 702

Polyvinyl Chloride Resin 702 is a high molecular weight, suspension-grade polyvinyl chloride resin with a K-value around 70–72. It is specifically formulated for use in soft and flexible PVC products due to its excellent plasticizer absorption and high mechanical strength. Its superior elongation, thermal stability, and processability make it highly suitable for calendaring, extrusion, injection molding, and dip molding operations. PVC Resin 702 is extensively used across the cable, synthetic leather, film, and footwear industries.

PVC K67

PVC K67 is a general-purpose polyvinyl chloride resin with a K-value of 67, indicating a medium molecular weight suitable for rigid applications. It is a white, free-flowing powder commonly used in the production of rigid PVC products such as pipes, fittings, profiles, and sheets. PVC K67 offers excellent processability, good mechanical strength, chemical resistance, and dimensional stability, making it ideal for a wide range of industrial and construction applications.

Styrene Polymer Copolymer

Styrene Polymer Copolymer is a high-performance copolymer consisting primarily of styrene combined with other monomers such as acrylonitrile or butadiene, designed to offer enhanced mechanical properties, chemical resistance, and processability. Supplied in bulk packaging of 230kg, it is widely used in plastics, adhesives, coatings, and rubber industries. This copolymer provides excellent toughness, thermal stability, and versatility, making it suitable for demanding industrial applications.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders