Nitric Acid Extra pure

$ 30.40 Original price was: $ 30.40.$ 30.34Current price is: $ 30.34.

Dynamic Trolley

$ 34.93 Original price was: $ 34.93.$ 34.83Current price is: $ 34.83.

Lab liquid level

$ 11.72 Original price was: $ 11.72.$ 11.61Current price is: $ 11.61.

Whatsapp Order

The Lab Liquid Level is a precision measuring instrument used to detect and indicate the level of liquids in laboratory containers, tanks, or systems. Designed for accuracy and ease of use, it helps scientists and technicians monitor fluid levels during experiments, processing, or storage. Typically constructed from chemically resistant materials, Lab Liquid Levels are compatible with various liquids including corrosive and volatile substances. They are essential tools for maintaining controlled conditions in chemical, pharmaceutical, and research laboratories.

Description

Table of Contents

Toggle

Lab liquid level

Primary Uses

- Laboratory and Industrial Applications

- Measures and monitors liquid levels in lab glassware, tanks, and reaction vessels.

- Used to ensure accurate reagent volumes during chemical processes.

- Supports fluid management in pharmaceutical production and research.

- Employed in quality control laboratories for precise liquid measurement.

- Helps maintain safety by preventing overfilling or depletion of critical fluids.

Secondary Uses

- Research and Educational Settings

- Utilized in educational labs for training in fluid dynamics and measurement.

- Applied in industrial pilot plants for monitoring process fluids.

- Suitable for environmental testing involving liquid sample volume monitoring.

KEY PRODUCT FEATURES

1. Basic Identification Attributes

- Material: Chemically resistant plastics, glass, or stainless steel components

- Design: Visual indicators such as float gauges, sight tubes, or electronic sensors

- Compatibility: Suitable for aqueous and organic solvents, acids, and bases

2. Physical & Chemical Properties

- Chemical Resistance: Withstands exposure to acids, alkalis, and solvents

- Accuracy: High precision level detection for reliable measurements

- Durability: Resistant to corrosion, temperature variations, and mechanical wear

3. Safety & Hazard Attributes

- Minimizes risks associated with overfilling or spillages

- Constructed to prevent contamination of measured liquids

- Requires careful handling to avoid breakage of glass components

4. Storage & Handling Attributes

- Store in dry, stable environments protected from impact

- Clean regularly to maintain accuracy and prevent contamination

- Inspect for cracks or damage before use

5. Regulatory & Compliance Attributes

- Manufactured in compliance with laboratory equipment safety standards

- Suitable for GMP and GLP compliant laboratories

6. Environmental & Health Impact

- Components made from recyclable materials where applicable

- Encourages responsible fluid management to reduce waste and hazards

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- Use appropriate PPE when handling liquids and instruments

- Avoid sudden temperature changes to prevent material damage

- Follow chemical handling protocols for liquids being measured

First Aid Measures

- For glass breakage, clean wounds and seek medical attention if necessary

- In case of chemical exposure, follow relevant first aid procedures

Firefighting Measures

- Non-flammable instrument materials

- Use appropriate extinguishing methods for nearby combustible materials

Related products

Balance Electronic Ohaus Adventurer

The Balance Electronic Ohaus Adventurer is a high-precision electronic weighing instrument designed for laboratory, educational, and industrial applications. It offers accurate and reliable measurement with user-friendly features including a backlit display, multiple weighing units, and advanced calibration options. This balance is suitable for general weighing tasks, formulation, and quality control processes where precision and ease of use are critical.

Balance Spring

The Balance Spring is a fundamental mechanical component used in balances and scales to measure weight through elastic deformation. It converts force into measurable displacement, enabling precise weight determination in various laboratory and industrial balances. Manufactured from high-quality, durable metals with excellent elastic properties, the balance spring ensures consistent performance and longevity under repeated use. It is essential for maintaining accuracy and reliability in mechanical weighing devices.

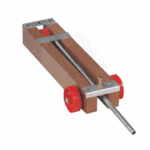

Bar and Gauge Apparatus

The Bar and Gauge Apparatus is a precision instrument used for measuring and comparing lengths, thicknesses, and distances in laboratory and industrial environments. It typically consists of calibrated bars, gauges, and scale components designed for accuracy in dimensional measurements. This apparatus is essential for quality control, calibration tasks, and research applications requiring precise measurement standards. Manufactured from durable materials such as stainless steel or hardened alloys, the Bar and Gauge Apparatus ensures reliable performance and longevity under regular use.

Barometer Tubes

Barometer Tubes are precision glass tubes used in barometers to measure atmospheric pressure. These tubes are typically filled with mercury or other suitable liquids and are sealed to allow accurate pressure readings based on liquid column height. Barometer tubes are essential components in meteorological instruments and laboratory equipment for pressure measurement and environmental monitoring. Manufactured with high-quality, clear glass, they provide durability, clarity, and accurate fluid displacement for precise readings.

Deionizer With 4 Elga Cans

Deionizer with 4 Elga Cans is a high-capacity water purification system engineered for continuous production of deionized water in laboratory and industrial environments. The system uses four Elga mixed-bed ion exchange cartridges working in parallel or series to ensure extended operation, high throughput, and superior water quality. It removes dissolved ions and minerals effectively, producing ultra-low conductivity water ideal for sensitive analytical, biochemical, and production processes. The modular setup allows for easy replacement and maintenance, making it a reliable solution for facilities with high-purity water demands.

Laboratory stop watch

The Laboratory Stop Watch is a precision timing device used in laboratories to accurately measure time intervals during experiments and processes. Designed for reliability and ease of use, it features start, stop, and reset functions, often with digital or analog displays. This stopwatch is essential for kinetic studies, reaction timing, process control, and any experiment requiring precise time measurement. Durable and portable, it is suitable for various scientific, educational, and industrial laboratory applications.

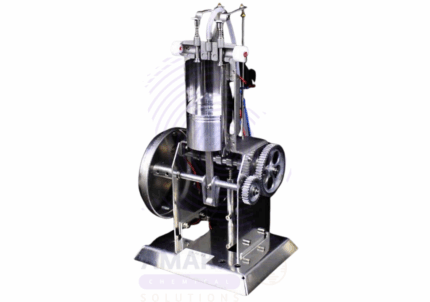

Model Diesel Engine

A Model Diesel Engine is a precision laboratory instrument used to measure very small electrical currents in the milliampere (mA) range. It is essential for experiments and procedures requiring accurate current measurements, particularly in physics and electronics labs. The device typically features a sensitive needle gauge or digital display, calibrated for fine resolution of low current levels. Compact and robust, millie ammeters are designed for easy integration into circuits and offer reliable performance for research, educational, and industrial applications.

Tuning fork

Tuning fork consists of eight precision-engineered metal forks, each designed to vibrate at specific musical or scientific frequencies. These forks are used in laboratory, medical, and educational settings for sound frequency testing, auditory research, and vibration experiments. Made from high-quality stainless steel or aluminum alloys, the set offers durability and consistent acoustic performance. The forks produce clear, sustained tones when struck, making them valuable tools for hearing assessments, resonance studies, and acoustic calibrations.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders