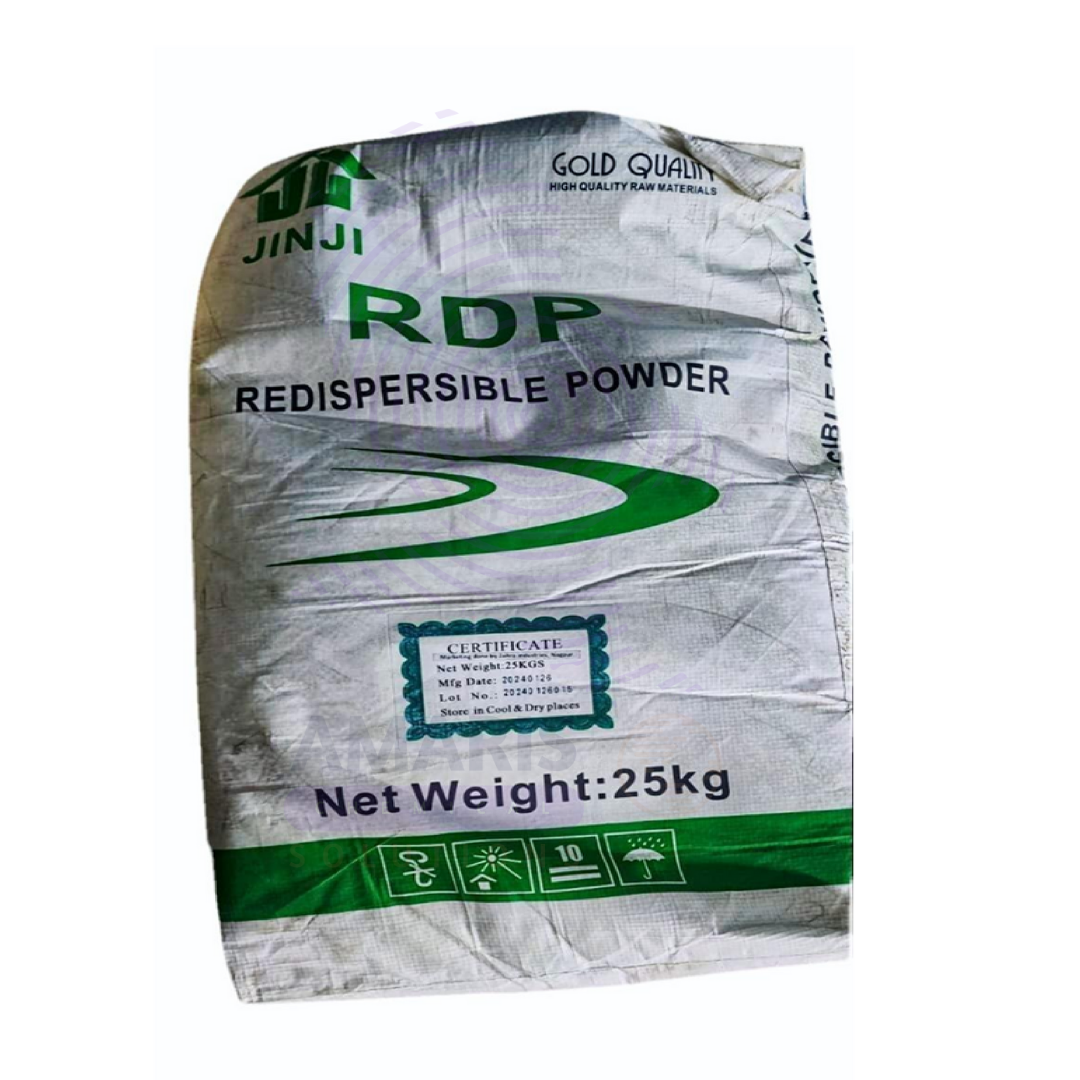

Redispersible Powder

Whatsapp Order

Redispersible Powder (RDP) is a free-flowing, white powder obtained by spray-drying a water-based emulsion of polymers, typically vinyl acetate-ethylene (VAE), acrylic, or styrene-butadiene. When mixed with water, RDP re-emulsifies to form a stable dispersion with excellent adhesive, flexible, and film-forming properties. It is widely used in dry-mix construction materials to enhance workability, flexibility, impact resistance, water retention, and adhesion. The product is supplied in moisture-resistant 25kg bags and is compatible with cement, gypsum, and other mineral binders.

Description

Table of Contents

Toggle

Redispersible Powder

Primary Uses

- Construction Industry

- Used in tile adhesives and tile grouts to enhance adhesion, flexibility, and water resistance.

- Incorporated in cement and gypsum-based plasters, renders, and skim coats to improve workability and reduce cracking.

- Added to self-leveling floor compounds for better flow and strength.

- Used in external insulation finishing systems (EIFS) to provide flexibility and adhesion to insulation panels.

- Improves crack-bridging ability and tensile strength in waterproofing membranes and coatings.

- Enhances mortar and repair compounds for structural patching and overlays.

- Used in decorative finishes and textured coatings for improved cohesion and surface smoothness.

- Dry Mix Mortars

- Enhances water retention, open time, and adhesion in ready-mix dry mortars.

- Reduces shrinkage and improves durability in repair mortars and grouts.

- Essential in thermal insulation mortars for bonding EPS/XPS boards.

- Paints & Coatings

- Used in powder-based paints and primers to allow redispersion with water during application.

- Improves film formation and flexibility in elastomeric and cementitious coatings.

Secondary Uses

- Ceramics and Stone Bonding

- Used in ceramic tile adhesives for vertical or high-traffic installations where strong bonding is required.

- Waterproofing Systems

- Added to bitumen- or cement-based waterproofing membranes to increase flexibility and adhesion.

- Insulation Systems

- Used in soundproofing and fire-resistant mortars where elasticity and bonding are critical.

- Masonry Repair

- Incorporated into crack repair fillers and façade renovation products for lasting adhesion and reduced brittleness.

- DIY Repair Products

- Used in home repair dry powders for patching and filling small surface defects.

KEY PRODUCT FEATURES

1. Basic Identification Attributes

- Chemical Name (IUPAC): Varies by composition (e.g., vinyl acetate-ethylene copolymer)

- Common/Trade Name: Redispersible Powder

- CAS Number: Varies by polymer type

- HS Code: 3905.91.00

- Synonyms: RDP; redispersible polymer powder; re-emulsifiable polymer

2. Physical & Chemical Properties

- Physical State: Free-flowing powder

- Color & Odor: White or off-white; mild or neutral odor

- Solubility: Dispersible in water

- Bulk Density: 300–600 kg/m³ (typical)

- pH: 5.0–9.0 (in water dispersion)

- Particle Size: Fine powder; typically < 200 µm

- Film Formation Temperature (MFFT): ~0–10°C depending on polymer type

3. Safety & Hazard Attributes

- GHS Classification: Not hazardous under normal conditions

- Toxicity: Non-toxic; avoid inhalation of dust

- Exposure Limits: Use dust control measures; refer to SDS for occupational limits

4. Storage & Handling Attributes

- Storage Conditions: Store in a cool, dry place away from humidity and direct sunlight

- Container Type: 25kg paper bags with PE liner or valve bags

- Shelf Life: Typically 6–12 months in sealed packaging under dry conditions

- Handling Precautions: Avoid generating dust; use in well-ventilated areas; reseal opened bags properly

5. Regulatory & Compliance Attributes

- Complies with: Industry standards for construction additives (e.g., EN 12004 for tile adhesives)

- VOC Content: Very low or zero VOC

- May conform to LEED and green building requirements

- Non-flammable, APEO-free, formaldehyde-free (depending on grade)

6. Environmental & Health Impact

- Biodegradability: Not readily biodegradable; inert polymer

- Ecotoxicity: Low; safe for use in construction under normal conditions

- Bioaccumulation: Not expected

- Waste Disposal: Dispose of in accordance with local regulations for construction materials

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- PPE Required: Dust mask or respirator, gloves, and safety goggles

- Handling Guidelines: Minimize dust; ensure ventilation; avoid breathing airborne particles

- Storage Measures: Keep containers tightly closed and stored in a dry environment to prevent clumping and degradation

First Aid Measures

- Inhalation: Move to fresh air; seek medical help if respiratory irritation occurs

- Skin Contact: Wash with soap and water; consult a physician if irritation persists

- Eye Contact: Rinse cautiously with water for several minutes; remove contact lenses if present; get medical attention if discomfort continues

- Ingestion: Rinse mouth with water; not expected to be toxic, but consult a doctor if necessary

Firefighting Measures

- Fire Hazards: May burn if exposed to extreme heat; polymer dust may be combustible

- Extinguishing Media: Foam, dry chemical, CO₂, or water spray

- Special Precautions: Use protective gear and breathing apparatus

- Hazardous Combustion Products: Carbon monoxide (CO), carbon dioxide (CO₂), and other polymer degradation products

Related products

Domacryl

Domacryl is a high-performance acrylic polymer latex designed for use as a binder in water-based coatings, adhesives, sealants, and construction materials. It is a styrene-acrylic copolymer emulsion offering excellent film formation, adhesion, durability, and chemical resistance. Domacryl provides superior mechanical strength and flexibility in formulated products, making it ideal for applications requiring long-lasting protection and enhanced aesthetic qualities. The polymer is supplied as a stable aqueous dispersion with approximately 50% solids content, packed in bulk (190 kg drums) for industrial use.

Hycryl

Hycryl is a specialized acrylic copolymer resin designed primarily for industrial and cosmetic applications. It appears as a white to off-white powder or granules with excellent film-forming, adhesive, and thickening properties. Known for its compatibility with a wide range of solvents and plasticizers, Hycryl 77 provides excellent clarity, flexibility, and durability in coatings, adhesives, and personal care formulations. Its balanced molecular weight and functional groups enable it to deliver strong binding and aesthetic properties in both aqueous and solvent-based systems.

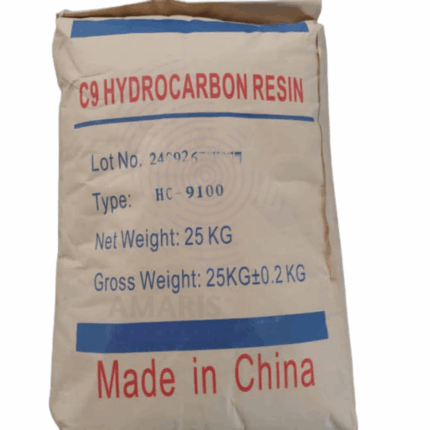

Hydrocarbon Resins

Hydrocarbon Resins C5 And C9 Petroleum Resins are synthetic petroleum-derived resins produced through the polymerization of C5 (pentene) and C9 (nonene) fraction monomers. These resins appear as pale yellow to amber solid materials, usually in pellet or flake form, characterized by tackifying and adhesive properties. C5 resins are derived from aliphatic hydrocarbons, while C9 resins originate from aromatic hydrocarbons. Often blended, these resins provide a balance of hardness, tackiness, and compatibility with various polymers. Widely used as tackifiers, binders, and modifiers, C5 & C9 hydrocarbon resins enhance performance in adhesives, coatings, rubber compounding, and more.

Linseed Oil Alkali Refined

Linseed Oil Alkali Refined is a vegetable oil extracted from flax seeds and then refined using alkali treatment to remove impurities, free fatty acids, and gums. This refining process enhances the oil’s stability, color, and odor, making it suitable for industrial, artistic, and manufacturing uses. It is a drying oil known for its excellent film-forming properties, quick drying time, and good adhesion to surfaces. Alkali refined linseed oil is widely used in paints, varnishes, inks, and as a raw material in chemical industries.

Linseed Oil Raw

Linseed Oil Raw is the unrefined, natural oil extracted from flax seeds through cold pressing or solvent extraction. It contains natural impurities such as gums, waxes, and free fatty acids, giving it a darker color and stronger odor compared to refined oils. Raw linseed oil is a drying oil known for its excellent film-forming and adhesive properties. It is widely used in traditional wood finishing, oil painting, and industrial applications where natural and slow-drying oil is preferred.

Nitro Cellulose

Nitro Cellulose is a highly flammable compound produced by nitrating cellulose through exposure to nitric acid and sulfuric acid. It is a versatile material widely used in coatings, lacquers, explosives, and propellants due to its film-forming properties and rapid drying capability. Nitro Cellulose is available in various grades depending on the nitrogen content and viscosity, making it suitable for industrial, commercial, and military applications.

Pigment Binder

Pigment Binder is a key component in paint, coating, and ink formulations that serves to bind pigment particles together and adhere them to the substrate. It provides mechanical strength, durability, and resistance to environmental factors such as moisture, UV radiation, and chemicals. Pigment binders influence the finish, gloss, flexibility, and adhesion properties of the final product, making them essential for high-performance coatings in various industries.

Styrene Acrylic

Styrene Acrylic is a copolymer emulsion combining styrene and acrylic monomers, widely used as a versatile binder in coatings, adhesives, and construction materials. It offers excellent film-forming properties, adhesion, water resistance, and durability. This product enhances the performance and longevity of paints, sealants, textiles, and paper coatings, with flexibility for both indoor and outdoor applications. Styrene Acrylic emulsions are designed to meet stringent industrial and environmental standards.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders