Equilateral Prism Glass

$ 33.75 Original price was: $ 33.75.$ 33.67Current price is: $ 33.67.

Siphon Pump

$ 11.79 Original price was: $ 11.79.$ 11.61Current price is: $ 11.61.

Slinky springs

$ 12.58 Original price was: $ 12.58.$ 12.43Current price is: $ 12.43.

Whatsapp Order

Slinky Springs are helical coil springs made from metal or plastic materials, widely used as demonstration and educational tools in physics and engineering laboratories. These springs exhibit elastic properties, capable of stretching and compressing while returning to their original shape, making them ideal for teaching concepts such as harmonic motion, wave propagation, and energy transfer. Available in various sizes and coil thicknesses, slinky springs serve as practical models for studying mechanical behavior, oscillations, and spring constants in both academic and research settings.

Description

Table of Contents

Toggle

Slinky springs

Primary Uses

- Laboratory Applications

- Demonstrate principles of elasticity, Hooke’s Law, and harmonic motion in physics education.

- Model wave propagation and energy transfer in oscillatory systems.

- Used in experiments involving potential and kinetic energy transformations.

- Aid in studying spring constants and mechanical properties of materials.

- Serve as hands-on teaching aids in classrooms and labs.

Secondary Uses

- Utilized in engineering research for prototype testing of spring mechanisms.

- Employed in mechanical device design and stress analysis demonstrations.

KEY PRODUCT FEATURES

1.Basic Identification Attributes

- Material: Metal (steel or alloy) or durable plastic coils.

- Design: Helical coil spring with uniform pitch and diameter.

- Sizes: Available in multiple lengths and coil thicknesses.

2.Physical & Chemical Properties

- Elasticity: High elastic limit allowing repeated stretching and compression.

- Durability: Resistant to deformation under normal usage.

- Finish: Metal springs often coated to resist corrosion; plastic springs are chemically inert.

3.Safety & Hazard Attributes

- Potential for snapping or pinching if overstretched or mishandled.

- Sharp coil edges may cause minor injuries.

4.Storage & Handling Attributes

- Store in a dry, dust-free environment to prevent corrosion or damage.

- Handle gently to avoid deformation or injury.

5.Regulatory & Compliance Attributes

- Manufactured following safety standards for educational tools and lab apparatus.

6.Environmental & Health Impact

- Metal springs are recyclable; plastic variants depend on polymer type.

- Proper disposal and recycling recommended.

SAFETY HANDLING PRECAUTIONS

safety Handling Precautions

- Use caution to avoid pinching fingers when stretching or compressing.

- Wear protective eyewear during vigorous demonstrations to prevent eye injury.

First Aid Measures

- For minor cuts or pinches, clean the affected area and apply antiseptic.

- Seek medical attention if injury is severe.

Firefighting Measures

- Metal springs are non-flammable; plastic springs may be combustible depending on material.

- Use appropriate extinguishing methods for surrounding materials.

Related products

Bare Enamelled Copper Wire

Bare Enamelled Copper Wire is a high-quality electrical conductor coated with a thin layer of insulating enamel. It is widely used in electrical and electronic applications where insulation and durability are required without adding bulk. The enamel coating provides excellent resistance to heat, abrasion, and chemicals, making it suitable for winding coils, transformers, motors, and inductors. The bare enamelled copper wire ensures efficient conductivity combined with insulation properties, ideal for both laboratory research and industrial manufacturing processes.

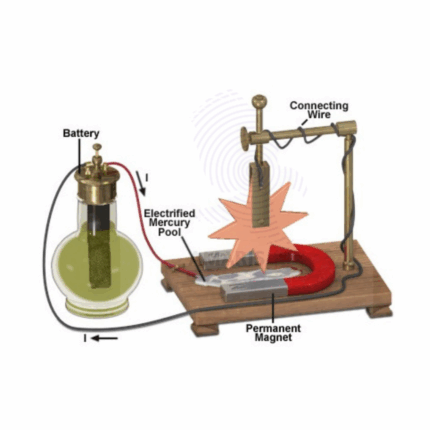

Barlows Wheel Apparatus

Barlows Wheel Apparatus is a classic physics demonstration device used to illustrate electromagnetic effects, specifically the principles of electric motors and the interaction between magnetic fields and electric current. It consists of a rotating wheel in contact with an electric circuit and a magnetic field, demonstrating motion generated by electromagnetic forces. The apparatus is widely used in educational laboratories to teach fundamental concepts of electromagnetism and motor action, as well as in industrial training for understanding motor components and operation.

Bell in Vacuum

Bell in Vacuum is a crucial component used in vacuum systems to create an airtight seal and protect sensitive equipment from atmospheric contamination. Typically made of durable, corrosion-resistant materials, it forms part of vacuum chambers or devices requiring controlled environments. The bell ensures the maintenance of vacuum integrity by preventing air ingress, making it essential for experiments and industrial processes that depend on low-pressure or vacuum conditions.

Crucible Tongs

Crucible Tongs are specialized metal tools designed for safely handling hot crucibles, evaporating dishes, and other laboratory apparatus exposed to high temperatures. Made from durable, heat-resistant metals such as stainless steel or nickel-plated steel, these tongs provide a firm grip, ensuring the safe transfer of heated items during laboratory procedures, including heating, melting, and chemical reactions.

Daniel cell

The Daniel Cell is a classic electrochemical cell consisting of zinc and copper electrodes immersed in their respective sulfate solutions and connected by a salt bridge. It generates electrical energy through redox reactions and is used primarily for educational and laboratory demonstrations in electrochemistry.

Dip Circle

A Dip Circle is a precision scientific instrument used for measuring the magnetic dip or inclination angle of the Earth’s magnetic field at a specific location. It consists of a magnetic needle or dip needle mounted on a graduated circular scale, which can rotate freely in the vertical plane. The instrument allows geologists, physicists, and surveyors to determine the angle between the horizontal plane and the Earth’s magnetic field lines, an important parameter in geomagnetic studies and navigation. Dip circles are commonly employed in academic research, mineral exploration, and educational demonstrations to analyze variations in Earth’s magnetism and assist in directional orientation.

Dip Needle Complete

Dip Needle Complete is a fully assembled and calibrated magnetic dip measurement instrument used for precise determination of the Earth’s magnetic inclination angle. This complete apparatus includes a magnetized dip needle mounted on a low-friction pivot within a protective housing, accompanied by a graduated circular scale for accurate angular readings. The instrument is designed for use in geophysical surveys, educational labs, and research institutions to study Earth’s magnetic field behavior. The complete setup ensures reliable, repeatable measurements with enhanced durability and ease of use, suitable for both field and laboratory environments.

Dynamo Working Model

Dynamo Working Model is a functional educational device designed to demonstrate the conversion of mechanical energy into electrical energy through electromagnetic induction. It includes components such as a rotating armature, coil windings, and magnets to simulate real-life dynamo operation. This model is widely used in physics and engineering laboratories, schools, and technical institutions for practical understanding of electricity generation and electromechanical energy conversion.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders