⚪ Titanium Dioxide — The Brilliant White That Powers Everyday Innovation

If you’ve ever admired the clean brightness of white paint 🎨, the shimmer in sunscreen 🧴, or the vivid color in a coated tablet 💊 — chances are, you’ve already encountered Titanium Dioxide (TiO₂).

This seemingly simple white powder is one of the most widely used and valuable compounds in modern industry. Its unmatched opacity, brightness, and UV-protective properties make it a backbone ingredient in paints, plastics, cosmetics, food, and pharmaceuticals.

At Amaris Chemical Solutions, we believe in not just supplying top-quality materials, but also helping our customers understand what makes each chemical so vital — and Titanium Dioxide is a true star in that story. 🌟

🧪 What Exactly Is Titanium Dioxide?

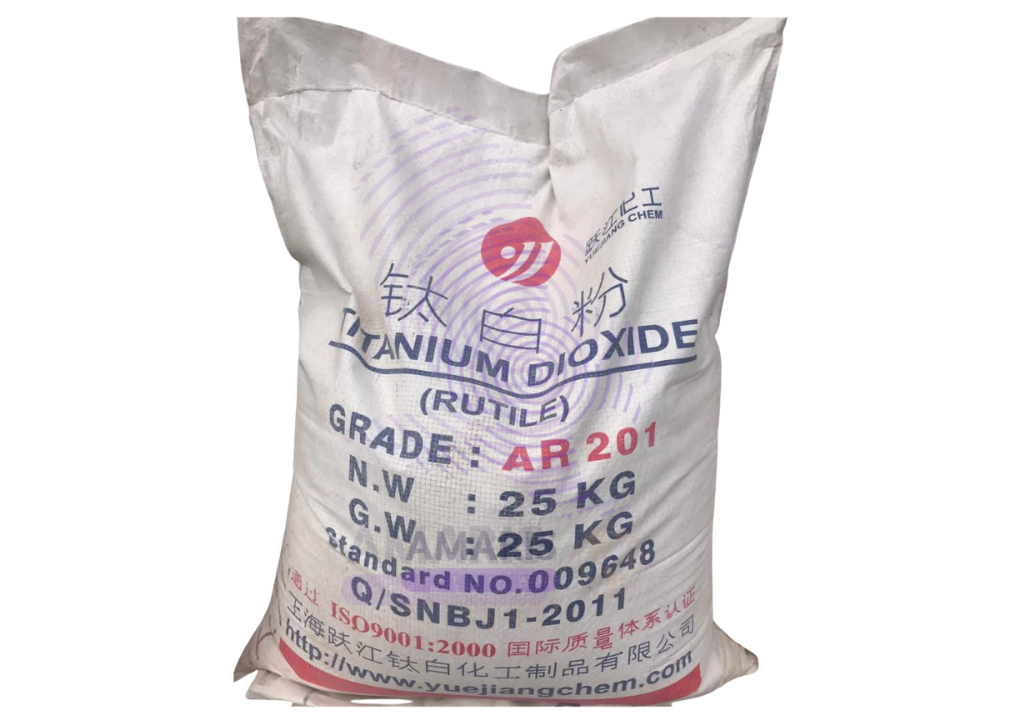

Titanium Dioxide, often abbreviated as TiO₂, is a naturally occurring oxide of titanium. It appears as a fine, brilliant white powder, insoluble in water, and incredibly stable under most conditions.

It’s found naturally in minerals like rutile, anatase, and brookite, which are mined and then refined to produce the pure, versatile pigment we know today.

Because of its high refractive index, Titanium Dioxide can scatter light more effectively than almost any other material, which explains why it’s so good at producing whiteness and opacity.

🎨 Titanium Dioxide in the Paint & Coatings Industry

This is where TiO₂ truly shines — quite literally! Its ability to reflect and scatter visible light gives paints their bright, clean finish and helps surfaces resist weathering.

Here’s why paint manufacturers depend on it:

- 🎨 Unmatched Opacity: A small amount provides excellent coverage.

- ☀️ UV Resistance: Protects paints and coatings from fading in sunlight.

- 💧 Chemical Stability: Withstands moisture, heat, and chemical exposure.

From industrial coatings and architectural paints to automotive finishes, Titanium Dioxide ensures that every color looks vivid, consistent, and long-lasting.

At Amaris Chemical Solutions, we provide technical-grade TiO₂ that meets stringent purity and particle-size requirements — helping industries achieve both aesthetic and protective excellence.

💊 Titanium Dioxide in Pharmaceuticals & Cosmetics

Beyond the world of paints, Titanium Dioxide plays an equally crucial role in healthcare and beauty.

In pharmaceuticals, TiO₂ is widely used as:

- A tablet coating agent that enhances appearance and protects sensitive ingredients.

- A colorant in pills, capsules, and medicinal suspensions.

- A light-protection barrier that prevents photodegradation of active compounds.

In cosmetics and skincare, it’s a must-have ingredient in:

- 🧴 Sunscreens: Titanium Dioxide acts as a physical UV filter, reflecting and scattering harmful UV rays rather than absorbing them.

- 💄 Makeup: Used in foundations, pressed powders, and lipsticks to add brightness and opacity.

- 🧼 Personal care products: Adds whiteness to lotions, creams, and soaps.

The best part? It’s non-toxic, non-reactive, and non-irritating, making it ideal for sensitive skin formulations.

🍬 Food Applications: E171 (When Purity Matters Most)

Titanium Dioxide also makes its way into the food industry, often labeled as E171 in ingredient lists. Its purpose? To whiten, brighten, and stabilize.

Common uses include:

- 🍭 Coating candies and chewing gum.

- 🧁 Whitening icing, fillings, and confectionery.

- 🥛 Enhancing the color of dairy and powdered beverages.

However, regulations around E171 are evolving, and the use of TiO₂ in foods is being reviewed in some regions. At Amaris, we stay ahead of global regulatory trends — providing guidance and compliance-ready materials for your formulations.

⚙️ Industrial and Environmental Uses

Titanium Dioxide’s versatility goes beyond color and cosmetics. In fact, it’s also a key player in advanced technologies:

- 🏭 Catalyst support in chemical reactions.

- 🌞 Photocatalyst in environmental purification — breaking down pollutants under UV light.

- 🧱 Additive in plastics and rubber, improving mechanical strength and resistance.

As sustainability becomes central to modern production, TiO₂’s role in self-cleaning coatings and air purification systems continues to grow. Its photocatalytic properties help decompose harmful organic compounds — proving that even a pigment can make a difference in environmental health 🌍.

🔬 Why Titanium Dioxide Remains Irreplaceable

Despite ongoing research into alternatives, Titanium Dioxide remains the gold standard for whiteness, opacity, and protection.

✅ Superior brightness: No other pigment matches its light-scattering efficiency.

✅ Thermal stability: Performs well in extreme conditions.

✅ Non-reactive: Safe and inert in most chemical systems.

✅ Multi-industry compatibility: Works in everything from paints to pills.

At Amaris Chemical Solutions, we ensure every batch of TiO₂ meets the highest purity and performance standards — supporting industries that depend on quality and consistency.

💬 Final Thoughts

From shining walls to glowing skin, Titanium Dioxide is a silent achiever — enhancing our world in ways we often overlook.

It’s the chemistry behind beauty, durability, and protection — a material that proves how a tiny white particle can brighten not just colors, but innovation itself ✨.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders