Nickel Sulphate

Whatsapp Order

Nickel Sulphate is an inorganic compound consisting of nickel and sulfate ions, typically found as a green crystalline solid. It is highly soluble in water and widely used as a key raw material in electroplating, chemical synthesis, and battery manufacturing. Nickel Sulphate plays a crucial role in producing nickel metal coatings, catalysts, pigments, and in the preparation of other nickel compounds. Due to its versatile chemical properties, it is essential in various industrial processes.

Description

Table of Contents

Toggle

Nickel Sulphate

Primary Uses

- Electroplating Industry

- Used extensively in nickel electroplating baths to provide corrosion-resistant and decorative coatings on metals.

- Employed for plating automotive parts, electronics, and household appliances.

- Battery Manufacturing

- Essential component in the production of nickel-cadmium (NiCd) and nickel-metal hydride (NiMH) rechargeable batteries.

- Chemical Industry

- Used in the synthesis of other nickel compounds such as nickel catalysts and nickel salts.

- Acts as a catalyst in hydrogenation and other chemical reactions.

- Pigments and Ceramics

- Used to produce green pigments for ceramics, glass, and paints.

Secondary Uses

- Electronics Industry

- Used in the manufacturing of electronic components and semiconductors.

- Laboratory Reagent

- Employed in laboratories for qualitative inorganic analysis and as a source of nickel ions.

- Catalysts

- Utilized in various catalytic processes in the petrochemical and pharmaceutical industries.

- Metal Treatment

- Used in metal finishing and surface treatment processes to improve corrosion resistance.

KEY PPRODUCT FEATURES

1. Basic Identification Attributes

- Chemical Name (IUPAC): Nickel(II) sulfate hexahydrate

- Common/Trade Name: Nickel Sulphate

- CAS Number: 7786-81-4

- HS Code: 2833.29.00

- Synonyms: Nickel sulfate, Nickel sulphate hexahydrate

2. Physical & Chemical Properties

- Physical State: Green crystalline solid

- Color & Odor: Green; odorless

- Solubility: Highly soluble in water

- Molecular Formula: NiSO₄·6H₂O (common hexahydrate form)

- Density: Approx. 2.38 g/cm³ (hexahydrate)

3. Safety & Hazard Attributes

- GHS Classification: Carcinogenic (Category 1B), harmful if inhaled or swallowed, skin sensitizer

- Toxicity: Toxic by ingestion and inhalation; may cause allergic skin reactions and respiratory sensitization

- Exposure Limits: Strict occupational exposure limits due to carcinogenicity

4. Storage & Handling Attributes

- Storage Conditions: Store in a cool, dry, well-ventilated area, away from incompatible materials such as strong oxidizers and reducing agents

- Container Type: Supplied in sealed plastic or metal drums

- Shelf Life: Stable for several years if stored properly

- Handling Precautions: Use personal protective equipment (PPE) to avoid inhalation and skin contact

5. Regulatory & Compliance Attributes

- Complies with REACH and OSHA regulations for hazardous chemicals

- Listed under hazardous substances due to carcinogenic and sensitizing properties

- Must be handled following strict environmental and safety regulations

6. Environmental & Health Impact

- Biodegradability: Not biodegradable

- Ecotoxicity: Highly toxic to aquatic life with long-lasting effects

- Bioaccumulation: Potential for bioaccumulation in aquatic organisms

- Carcinogenicity/Mutagenicity: Classified as a carcinogen; mutagenic potential under study

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- PPE Required: Use gloves, protective clothing, eye protection, and respirators as necessary

- Handling Guidelines: Use in well-ventilated areas or fume hoods; avoid dust and mist formation

- Storage Measures: Keep containers tightly closed; store away from incompatible substances

First Aid Measures

- Inhalation: Move to fresh air immediately; seek medical attention if breathing difficulties occur

- Skin Contact: Wash thoroughly with soap and water; seek medical help if rash or irritation develops

- Eye Contact: Rinse cautiously with water for at least 15 minutes; obtain medical attention if irritation persists

- Ingestion: Do not induce vomiting; seek immediate medical attention

Firefighting Measures

- Fire Hazards: Not flammable but may decompose to release toxic gases when heated

- Extinguishing Media: Use water spray, foam, dry chemical, or CO₂ extinguisher

- Special Precautions: Use self-contained breathing apparatus (SCBA) to avoid inhalation of hazardous fumes

- Hazardous Combustion Products: Nickel oxides, sulfur oxides, and other toxic gases

Related products

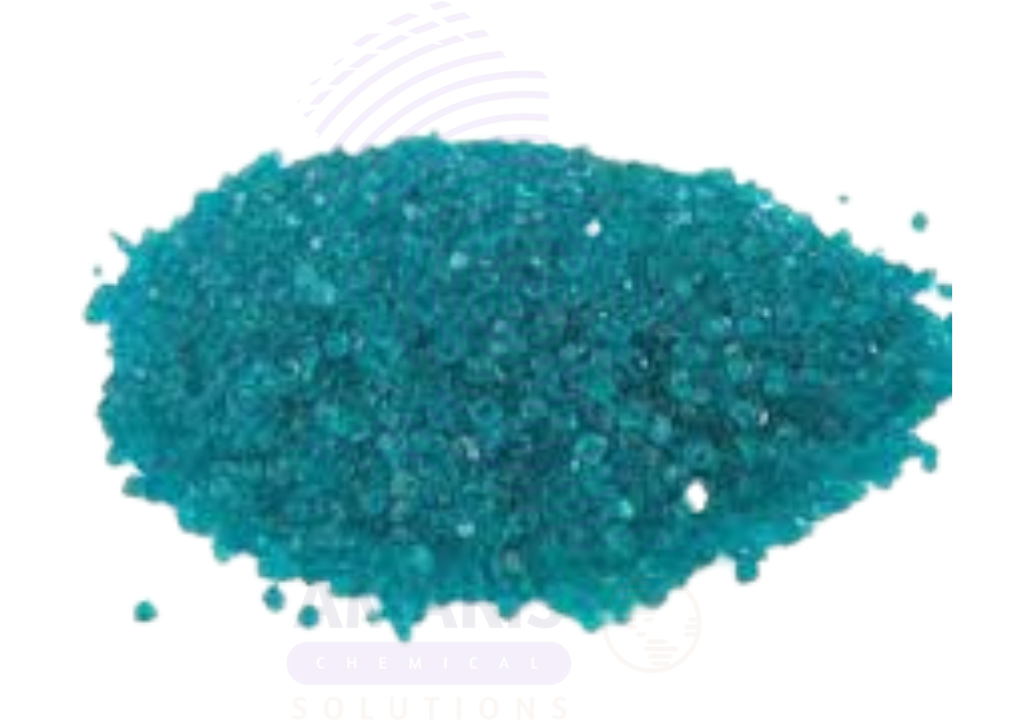

Ammonium Cupric Chloride

Ammonium Cupric Chloride is a blue-green crystalline inorganic compound composed of copper, ammonium, and chloride ions. It is widely used as a source of copper in agricultural fungicides and bactericides, as well as in electroplating, chemical synthesis, and textile dyeing. Its antimicrobial properties make it valuable for controlling fungal and bacterial infections in plants. Additionally, it serves as a precursor in various industrial and laboratory applications.

Carbon Black

Carbon Black Concentrate Dispersions are homogeneous, ready-to-use formulations consisting of high-quality carbon black uniformly dispersed in a compatible liquid or solid carrier system. These products are engineered to deliver precise, repeatable carbon black loading levels at concentrations of 15%, 25%, 40%, and 50%, enabling manufacturers to achieve consistent jetness, tint strength, UV protection, electrical conductivity, and reinforcement across a wide range of industrial applications. Each variant is identified by a unique product code (169FF, 121FF, 13FF, 32PP) denoting the specific carbon black grade, with the percentage indicating the exact weight concentration of carbon black in the dispersion. These products eliminate the handling hazards, dust contamination, and dispersion inconsistencies associated with raw powdered carbon black, while significantly improving manufacturing efficiency, color matching, and end-product performance. They are designed to be "let down" (diluted) into a compatible base material at recommended ratios to achieve the target carbon black level for specific formulation requirements. These are industrial-grade products and are not intended for food, pharmaceutical, or cosmetic applications unless explicitly certified otherwise.

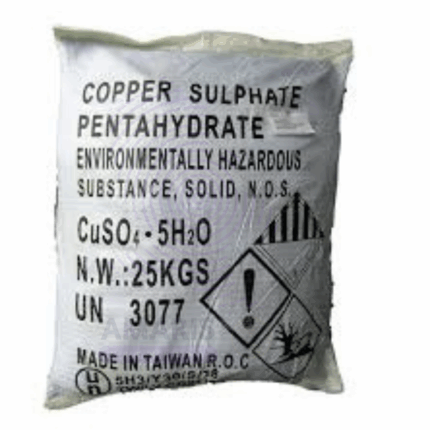

Copper Sulphate Pentahydrate

Copper Sulphate Pentahydrate (CuSO₄·5H₂O) is a bright blue crystalline solid widely used as a chemical reagent, agricultural fungicide, and analytical reagent. It consists of copper, sulfur, oxygen, and water molecules, forming a distinctive pentahydrate structure. This inorganic salt is highly soluble in water, exhibiting antifungal, algaecidal, and bactericidal properties. Copper Sulphate Pentahydrate is extensively employed in agriculture, industry, and laboratory applications due to its effectiveness, affordability, and well-understood chemistry.

leclanche cell

Leclanché Cell is a primary electrochemical cell commonly used as a standard dry cell battery. It consists of a zinc anode, a carbon rod cathode surrounded by manganese dioxide, and an electrolyte of ammonium chloride paste. Known for its reliability and portability, it is widely used in laboratory demonstrations, educational settings, and portable electrical devices. The cell provides a stable voltage output and serves as a practical example of electrochemical energy conversion.

Nickel Sulphate Extra Pure

Nickel Sulphate Extra Pure is a crystalline, green-colored compound of high purity, widely utilized in analytical, electrochemical, and industrial applications. It is primarily used in electroplating processes to deposit a uniform layer of nickel onto metal surfaces, enhancing corrosion resistance and aesthetic appeal. Its consistent composition makes it ideal for high-precision electroforming and battery component manufacturing, especially in nickel-cadmium and nickel-metal hydride batteries.

In laboratories, it serves as a reagent for chemical analysis, particularly in qualitative and quantitative detection of nickel ions. It is also involved in catalyst production, ceramic coloring, and metal surface treatment. The Extra Pure grade guarantees minimal impurities, ensuring reliable performance in sensitive experimental setups. Due to its toxic and irritant nature, it should be handled with appropriate personal protective equipment and stored in a cool, dry place in tightly closed containers.

Potassium Chloride BP

Potassium Chloride BP (British Pharmacopoeia grade) is a high-purity, pharmaceutical-grade potassium salt widely used in medical, agricultural, and industrial applications. It is a white crystalline solid that is highly soluble in water and serves as an essential source of potassium ions in various biochemical and physiological processes. The BP grade ensures strict compliance with purity and quality standards, making it suitable for pharmaceutical formulations and clinical use.

Sodium Cyanide

Sodium Cyanide is a highly toxic, white crystalline compound used primarily in the mining industry for gold and silver extraction via cyanidation. It acts as a powerful chemical reagent and is employed in various industrial processes including metal plating, chemical synthesis, and organic chemistry. Due to its hazardous nature, strict handling and storage protocols are essential.

Sodium Sulphate

Sodium Sulphate (Na₂SO₄) is a white crystalline powder or granule, odorless and highly soluble in water. This 25kg packaged product is widely used in detergents, glass manufacturing, chemical industries, and pulp and paper processing. It acts as a filler, bulking agent, and drying agent, with excellent stability and non-reactivity under standard storage conditions. Its cost-effectiveness and availability make it an essential raw material in many industrial processes.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders

![Nickel Sulphate [NiSO4(H2O)6] Extra Pure Amaris Chemicals](https://amarischemicalsolutions.com/wp-content/uploads/2025/08/Nickel-Sulphate-NiSO4H2O6-Extra-Pure-Amaris-Chemicals-430x430.png)