Phosphoric acid Technical Grade

$ 3.12 Original price was: $ 3.12.$ 3.10Current price is: $ 3.10.

Whatsapp Order

Phosphoric Acid Technical Grade is a concentrated, inorganic acid primarily used in industrial applications. It typically contains minor impurities compared to food or pharmaceutical grades but maintains excellent performance as an acidulant, rust remover, and intermediate chemical. This grade is widely used in manufacturing fertilizers, detergents, metal treatment, and other industrial processes where high purity is not critical but effective acidic properties are required.

Description

Table of Contents

Toggle

Phosphoric acid Technical Grade

Primary Uses

- Fertilizer Manufacturing

- Raw material for producing phosphate fertilizers such as monoammonium phosphate (MAP) and diammonium phosphate (DAP).

- Applied in the wet process for phosphate rock treatment.

- Metal Treatment & Cleaning

- Used as a rust remover and metal surface cleaner to etch and prepare metals before coating or plating.

- Employed in pickling baths to remove oxides and scale from steel and other metals.

- Detergents & Cleaning Agents

- Ingredient in detergent formulations for its acidity and chelating properties.

- Used in industrial cleaning products to remove mineral deposits and grease.

- Chemical Intermediate

- Serves as a precursor for manufacturing various phosphate salts and specialty chemicals.

Secondary Uses

- Water Treatment

- Used for pH adjustment and corrosion control in boilers and cooling towers.

- Concrete Additives

- Utilized as a retardant and plasticizer in concrete admixtures.

- Animal Feed

- Occasionally used in mineral supplements for livestock feed (subject to purity requirements).

- Laboratory Reagent

- Used in industrial laboratories for titrations and chemical syntheses.

KEY PRODUCT FEATURES

1. Basic Identification Attributes

- Chemical Name (IUPAC): Phosphoric acid

- Common/Trade Name: Phosphoric Acid Technical Grade

- CAS Number: 7664-38-2

- HS Code: 2809.20.00

- Synonyms: Orthophosphoric acid, Technical grade phosphoric acid

2. Physical & Chemical Properties

- Physical State: Liquid

- Color & Odor: Colorless, odorless to slightly acidic odor

- Concentration: Typically 75-85% (varies by supplier)

- pH: ~1 (1M solution)

- Density: Approx. 1.6 – 1.7 g/cm³

- Solubility: Miscible with water

3. Safety & Hazard Attributes

- GHS Classification: Corrosive (causes severe skin burns and eye damage)

- Toxicity: Corrosive; harmful if swallowed or inhaled

- Exposure Limits: Follow occupational safety guidelines

4. Storage & Handling Attributes

- Storage Conditions: Store in corrosion-resistant containers, protected from moisture and heat

- Container Type: Supplied in drums or bulk tanks (varies)

- Shelf Life: Stable if stored correctly

- Handling Precautions: Use personal protective equipment; avoid skin and eye contact; ensure adequate ventilation

5. Regulatory & Compliance Attributes

- Complies with industrial chemical standards and safety regulations (e.g., REACH, OSHA)

- Not suitable for food or pharmaceutical use without further purification

6. Environmental & Health Impact

- Biodegradability: Inorganic acid, not biodegradable

- Ecotoxicity: Toxic to aquatic life at high concentrations

- Bioaccumulation: Not expected

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- PPE Required: Acid-resistant gloves, safety goggles, protective clothing, and face shield

- Handling Guidelines: Avoid direct contact, inhalation of vapors; work in well-ventilated areas

- Storage Measures: Store separately from bases, oxidizers, and metals

First Aid Measures

- Inhalation: Move to fresh air immediately; seek medical attention if breathing difficulty occurs

- Skin Contact: Rinse with water for at least 15 minutes; remove contaminated clothing; seek medical advice

- Eye Contact: Flush eyes with plenty of water for 15 minutes; seek urgent medical care

- Ingestion: Do not induce vomiting; rinse mouth; get immediate medical help

Firefighting Measures

- Fire Hazards: Non-flammable but may produce toxic phosphorus oxides when heated

- Extinguishing Media: Water spray, foam, dry chemical, or CO₂ for surrounding fires

- Special Precautions: Use full protective gear and self-contained breathing apparatus

- Hazardous Combustion Products: Phosphorus oxides

Related products

Calcium Hydroxide Hydrated Lime

Calcium Hydroxide Hydrated Lime, commonly known as Hydrated Lime or Slaked Lime, is an inorganic compound with the chemical formula Ca(OH)₂. It appears as a white, odorless, powder or crystalline solid. It is produced by treating quicklime (calcium oxide) with water in a process called slaking. Calcium Hydroxide is moderately soluble in water, forming a strongly alkaline solution known as limewater. It is widely used in construction, environmental, chemical, agricultural, and water treatment applications due to its caustic, neutralizing, and flocculating properties.

Ferrous Sulphide

Ferrous Sulphide (FeS) is an inorganic iron-sulfur compound appearing as a dark gray to black crystalline powder or solid. It has low solubility in water but reacts with acids to release hydrogen sulfide gas. It is used in numerous industrial and chemical processes due to its sulfide content and reactive properties. Ferrous Sulphide serves as a key intermediate in metallurgy, chemical synthesis, wastewater treatment, pigment production, and more.

Fuel Conditioner

Fuel Conditioner is a specialized chemical additive formulated to improve the performance, efficiency, and longevity of fuels such as gasoline, diesel, biodiesel, and kerosene. It typically contains detergents, corrosion inhibitors, stabilizers, lubricity enhancers, and combustion improvers. The product is designed to clean fuel injectors and carburetors, reduce engine deposits, prevent fuel oxidation, and enhance combustion efficiency. Fuel Conditioners help optimize fuel properties to reduce emissions, improve fuel economy, and protect fuel system components in vehicles, generators, and industrial machinery.

Guanidine Carbonate

Guanidine Carbonate is a white crystalline powder, highly soluble in water, with strong basicity and high nitrogen content. It’s a versatile chemical intermediate widely used in pharmaceuticals, agriculture, polymer chemistry, textiles, and laboratory research. Its buffering properties and reactivity make it valuable in synthesis, pH regulation, and as a nitrogen source.

Hydrogen Peroxide Food Grade

Hydrogen Peroxide Food Grade is a highly concentrated aqueous solution of hydrogen peroxide (H₂O₂), formulated specifically for use in food processing and related applications. It appears as a clear, colorless liquid with a slightly sharp, acrid odor. Renowned for its powerful oxidizing and bleaching properties, hydrogen peroxide is a strong antimicrobial agent and environmentally friendly disinfectant that decomposes into water and oxygen, leaving no harmful residues. The food-grade designation ensures compliance with strict purity standards, making it suitable for direct and indirect food contact uses, including sterilization, sanitation, and preservation.

Liquid Chlorine

Liquid Chlorine is a pale yellow-green, highly reactive chemical primarily composed of chlorine dissolved in water or as liquefied chlorine gas under pressure. It is widely used as a powerful disinfectant, bleaching agent, and oxidizer in water treatment, sanitation, and various industrial applications. Due to its strong antimicrobial properties, liquid chlorine effectively controls bacteria, viruses, algae, and other microorganisms, ensuring safe potable water and hygienic conditions.

Sulphuric Acid

Sulphuric Acid is a dense, highly corrosive, and strong mineral acid widely used as a fundamental chemical reagent and industrial raw material. It serves as a key component in fertilizer production, chemical synthesis, petroleum refining, and many other industrial processes. The 98% concentration is the concentrated, nearly pure form commonly utilized for manufacturing and processing applications demanding high acid strength and purity.

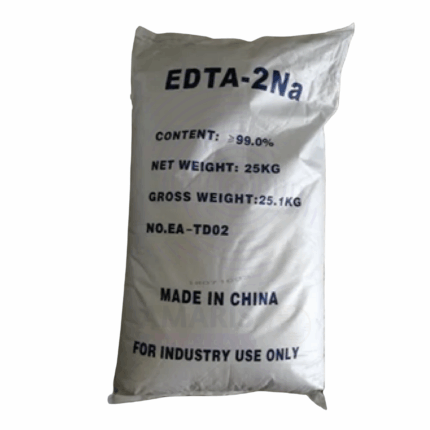

Trilium (EDTA)

Trilium EDTA is a high-purity, versatile chelating agent known chemically as ethylenediaminetetraacetic acid (EDTA) or its trisodium salt form. It is widely used across industries to bind and sequester metal ions, improving product stability and performance. Trilium EDTA effectively prevents metal ion contamination, controls hardness in water, enhances cleaning efficiency, and stabilizes formulations in pharmaceuticals, cosmetics, agriculture, and industrial applications. Its strong chelating properties make it an essential ingredient for complexation and metal ion control.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders