Engine Cleaner

$ 20.77 Original price was: $ 20.77.$ 19.73Current price is: $ 19.73.

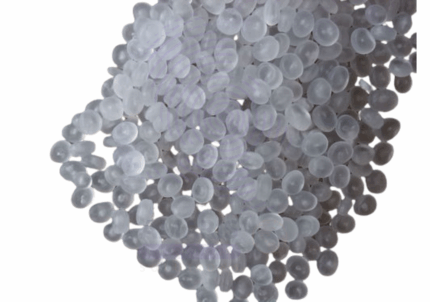

PET Resin (Polyethylene Terephthalate)

$ 38.46 Original price was: $ 38.46.$ 36.54Current price is: $ 36.54.

Whatsapp Order

PET Resin (Polyethylene Terephthalate) is a thermoplastic polymer resin of the polyester family, produced primarily from purified terephthalic acid (PTA) and monoethylene glycol (MEG). It exists in two main forms: amorphous (transparent) and semi-crystalline (opaque). In its technical/industrial grade, it is a clear, strong, and lightweight plastic material renowned for its excellent barrier properties against moisture and gases, high impact strength, and chemical resistance. It is a key raw material for manufacturing rigid containers and packaging but is not typically used for high-heat applications (like ovenware) or high-purity pharmaceutical uses in this grade. It is 100% recyclable (#1 plastic).

Description

Table of Contents

Toggle

PET Resin (Polyethylene Terephthalate)

Primary Uses

1. Packaging Industry

-

Bottle manufacturing: The predominant use for carbonated soft drink bottles, water bottles, juice bottles, and food containers via stretch blow molding.

-

Food packaging trays and clamshells: Used for thermoforming applications to produce transparent containers for fresh produce, baked goods, and ready meals.

-

Jars and containers: For packaging peanut butter, salad dressings, spices, and other food products.

2. Film and Sheet Production

-

Thermoforming sheets: Produced as amorphous sheets (APET) for blister packs and transparent display packaging.

-

Packaging films: Used as a component in high-barrier, flexible packaging laminates for snacks and perishable foods.

3. Textile and Fiber Industry

-

Polyester fiber production: A major feedstock for producing polyester staple fiber and filament used in clothing, upholstery, carpets, and industrial fabrics (e.g., tire cord).

Secondary Uses

1. Technical and Industrial Applications

-

Strapping: Used to produce strong, durable plastic strapping for palletizing and bundling.

-

Engineering resins: As a base material or blend component for glass-filled or other reinforced engineering plastics.

-

Blister and clamshell packaging: For consumer goods, electronics, and hardware items.

KEY PRODUCT FEATURES

1. Basic Identification Attributes

-

-

Chemical Name: Poly(ethylene terephthalate)

-

Common/Trade Name: PET Resin, Polyester Resin

-

CAS Number: 25038-59-9

-

Recycling Code: #1 (PETE)

-

-

Synonyms:

-

-

PETE

-

Polyester resin (thermoplastic)

-

Bottle-grade PET

-

2. Physical & Chemical Properties

-

Physical State: Solid pellets or flakes (recycled).

-

Color: Naturally transparent/colorless; can be compounded with colorants.

-

Melting Point: ~250 - 260°C

-

Glass Transition Temp (Tg): ~70 - 80°C

-

Density: ~1.33 - 1.38 g/cm³

-

Intrinsic Viscosity (IV): Key grade indicator (e.g., 0.70-0.85 dL/g for bottles).

-

Moisture Content: Must be < 0.005% (50 ppm) before processing (highly hygroscopic).

3. Safety & Hazard Attributes

-

Hazard Class (GHS): Generally not classified as hazardous. Solid polymer is non-toxic.

-

Processing Hazards: Thermal decomposition during high-temperature processing (>300°C) can release acetaldehyde and other volatile organic compounds (VOCs).

-

Exposure Limits: Dust exposure limits apply for respirable polymer dust (typically 10 mg/m³ total dust, 3 mg/m³ respirable fraction).

4. Storage & Handling Attributes

-

Storage Conditions: MUST be stored in a dry, sealed environment below 40°C and 40% relative humidity to prevent moisture absorption, which degrades the polymer during melting.

-

Container Type: Sealed aluminum-foil-lined bags, bulk silos, or boxes.

-

Shelf Life: Indefinite if kept dry and away from UV light.

-

Handling Precautions: Use standard industrial material handling. Ground equipment to prevent static discharge with fine flakes or powder.

5. Regulatory & Compliance Attributes

-

Food Contact Compliance: Virgin food-grade resins must comply with FDA 21 CFR or EU 10/2011 regulations for food contact materials.

-

Recycled Content: Regulations govern the use of post-consumer recycled (PCR) PET in new food contact applications.

6. Environmental & Health Impact

-

Biodegradability: Not biodegradable; persists in the environment if littered.

-

Recyclability: Highly recyclable (mechanical and chemical). A cornerstone of the circular economy for plastics.

-

Carbon Footprint: Lower than many alternatives like glass or aluminum for packaging when considering weight and transportation.

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

-

PPE Required: Safety glasses, gloves, and dust mask when handling fines or dust. Normal work clothing.

-

Handling Guidelines: Ensure material is thoroughly dried in a desiccant hopper dryer before processing to prevent hydrolysis and loss of properties.

-

Storage Measures: CRITICAL: Keep original packaging sealed until use. Use first-in, first-out (FIFO) inventory.

-

Hygiene Practices: Standard industrial hygiene.

First Aid Measures

-

Inhalation (dust): Move to fresh air.

-

Skin Contact: Wash with soap and water.

-

Eye Contact: Rinse with water.

-

Ingestion: Not anticipated. Rinse mouth. Seek medical advice if large amounts are swallowed.

Firefighting Measures

-

Fire Hazards: Combustible solid. Burns with a sooty, yellow flame and dripping.

-

Extinguishing Media: Water spray, foam, CO₂, dry chemical.

-

Special Precautions: Wear self-contained breathing apparatus (SCBA). Toxic fumes (carbon monoxide, acetaldehyde) are produced in fire.

-

Decomposition Products: Carbon monoxide, carbon dioxide, aromatic hydrocarbons.

Related products

Pigment Orange

Pigment Orange is a concentrated dispersion of synthetic orange pigment particles in a suitable carrier, designed to deliver bright, vivid orange coloration. It offers excellent stability, heat resistance, and chemical inertness, making it suitable for diverse industrial applications including paints, plastics, inks, and coatings. This pigment ensures consistent color strength and durability across a variety of substrates.

Polyvinyl Chloride Resin 701

Polyvinyl Chloride Resin 701 is a high-quality suspension-grade polyvinyl chloride resin with a K-value of approximately 70–71, indicating high molecular weight. It is widely used in the production of flexible PVC products where excellent strength, elongation, and plasticizer absorption are required. PVC Resin 701 offers superior mechanical properties, high thermal stability, and good compatibility with plasticizers, making it suitable for calendaring, extrusion, and molding applications in diverse industries.

Polyvinyl Chloride Resin 702

Polyvinyl Chloride Resin 702 is a high molecular weight, suspension-grade polyvinyl chloride resin with a K-value around 70–72. It is specifically formulated for use in soft and flexible PVC products due to its excellent plasticizer absorption and high mechanical strength. Its superior elongation, thermal stability, and processability make it highly suitable for calendaring, extrusion, injection molding, and dip molding operations. PVC Resin 702 is extensively used across the cable, synthetic leather, film, and footwear industries.

PP Raffia RH03( Wooven)

PP Raffia RH03( Wooven) is a woven polypropylene fabric made from homopolymer polypropylene resin, designed for high strength, durability, and excellent dimensional stability. It is widely used in the manufacturing of woven sacks, bags, and other flexible packaging solutions. The woven structure enhances tear resistance and load-bearing capacity, making it suitable for industrial and agricultural packaging applications.

Styrene Polymer Copolymer

Styrene Polymer Copolymer is a high-performance copolymer consisting primarily of styrene combined with other monomers such as acrylonitrile or butadiene, designed to offer enhanced mechanical properties, chemical resistance, and processability. Supplied in bulk packaging of 230kg, it is widely used in plastics, adhesives, coatings, and rubber industries. This copolymer provides excellent toughness, thermal stability, and versatility, making it suitable for demanding industrial applications.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders