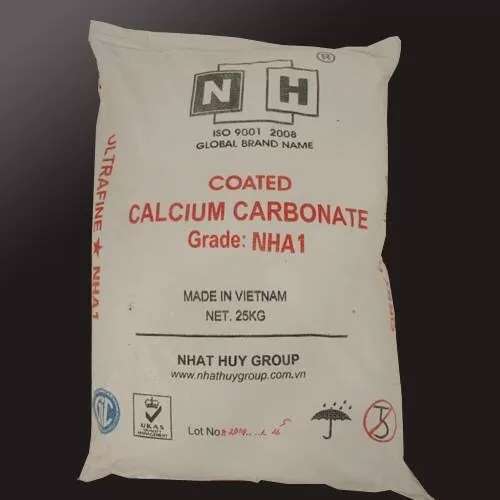

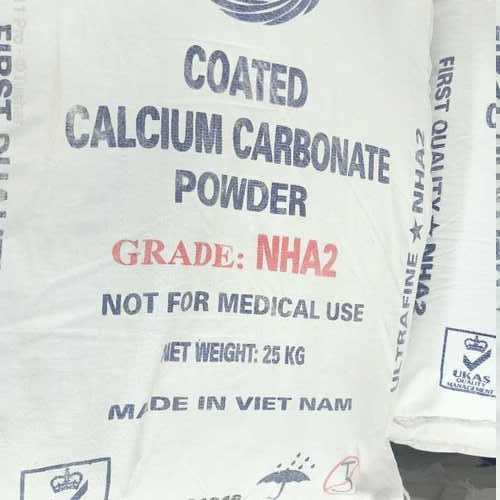

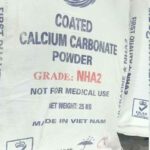

Calcium carbonate (Coated)

$3,500.00 Original price was: $3,500.00.$3,300.00Current price is: $3,300.00.

Calcium Carbonate (coated) refers to a form of calcium carbonate in which the individual particles of the mineral are coated or encapsulated with a layer of a different material. This layer can be composed of various substances, such as stearic acid, fatty acids, or other polymers. The purpose of the coating is to modify the surface properties of the calcium carbonate particles, such as their hydrophobicity or compatibility with other materials, making them more suitable for specific applications. Coated calcium carbonate is widely used in industries such as plastics, paper, paints, and coatings, where it can improve the properties of the final product, such as brightness, whiteness, and durability.

Calcium carbonate (Coated)

Calcium Carbonate (coated) has many uses in various industries due to its unique properties. Some of the major uses of coated calcium carbonate include:

- Plastics: Coated calcium carbonate is used as a filler in plastics to improve their strength, stiffness, and impact resistance. It also enhances the whiteness and opacity of plastic products, making them more visually appealing.

- Paper: Coated calcium carbonate is used as a filler in paper and board products to increase their brightness, opacity, and smoothness. It also improves the printability and ink retention of paper products.

- Paints and coatings: Coated calcium carbonate is used as a pigment and filler in paints and coatings to improve their hiding power, gloss, and durability. It also enhances the viscosity and stability of paint formulations.

- Adhesives and sealants: Coated calcium carbonate is used as a filler in adhesives and sealants to improve their strength and durability. It also enhances their rheology and thixotropy.

- Pharmaceuticals: Coated calcium carbonate is used as an excipient in pharmaceuticals to improve their flowability, compressibility, and stability. It also acts as a buffering agent and antacid.

Overall, coated calcium carbonate is a versatile material that has a wide range of applications in various industries. Its unique properties make it an essential ingredient in many products that we use every day.

| APPEARANCE |

Powdery – Fine, dry particles e.g., baking soda |

|---|---|

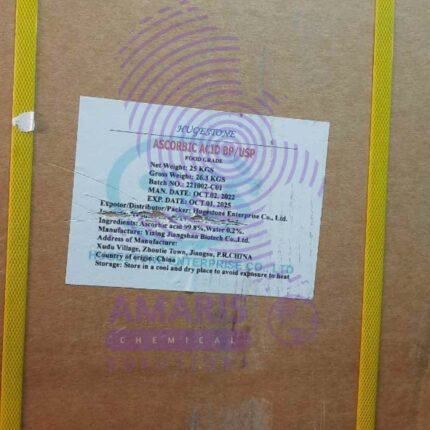

| AVAILABLE PACK SIZE |

25kg( Metal or Plastic Jerrycan/ Bucket, Bag, Box, Polythene bag, Carton bag) |

| COUNTRIES OF ORIGIN |

CHINA |

1. Basic Identification Attributes

- Chemical Name: Calcium carbonate, surface-treated

- CAS Number: 471-34-1 (base material)

- HS Code: 2836.50.00 (Calcium carbonate)

- Molecular Formula: CaCO₃ (with surface modifier)

- Synonyms: Surface-modified calcium carbonate, Stearate-coated CaCO₃, Treated GCC

2. Physical & Chemical Properties

- Physical State: Ultra-fine white powder

- Color & Odor: Bright white (94-98% ISO brightness); odorless

- Melting Point: 825°C (decomposition)

- Density: 2.6-2.8 g/cm³ (apparent)

- Solubility:

- Water: Insoluble (hydrophobic coating reduces wettability)

- Organic solvents: Improved dispersion vs uncoated

- pH Level: 8.5-9.5 (10% slurry)

- Coating Content: 0.5-3.0% (typically stearic acid or titanate)

- Particle Size: 0.7-3.0 μm (median)

3. Safety & Hazard Attributes

- Hazard Class (GHS): Not classified

- NFPA Ratings: Health: 0 | Flammability: 1 | Reactivity: 0

- Exposure Limits:

- Same as uncoated (dust concerns remain)

- Reactivity:

- Coating reduces acid reactivity

- Thermally stable to coating melt point

4. Storage & Handling Attributes

- Storage Conditions:

- Dry (<50% RH), sealed containers

- Avoid high temperatures (>60°C)

- Shelf Life: 24+ months

- Special Handling:

- Anti-static precautions for some coatings

- Dust control still required

Personal Protection

- Respiratory Protection: Use a NIOSH-approved N95 dust maskwhen handling in powdered form, especially in poorly ventilated areas.

- Eye Protection: Wear safety gogglesto prevent dust irritation.

- Skin Protection: Use nitrile or latex glovesif prolonged contact is expected.

- General Hygiene: Avoid inhalation and ingestion. Wash hands after handling.

Handling & Storage

- Store in a cool, dry, well-ventilatedarea, away from moisture and strong acids.

- Keep containers tightly sealedto prevent contamination and moisture absorption.

- Minimize dust generation—use local exhaust ventilationif handling large quantities.

- Avoid mixing with strong acids(may release CO₂ gas).

Spill Management

- For dry spills: Carefully sweep up (avoid dust generation) and dispose of in a sealed container.

- For wet spills: Absorb with inert material (e.g., vermiculite) and clean with water.

Inhalation

- Move to fresh air

- If breathing difficulties occur, seek medical attention.

Skin Contact

- Wash affected area with soap and water.

- If irritation or allergic reaction develops (due to coating agents), seek medical advice.

Eye Contact

- Rinse immediately with plenty of water for at least 15 minutes, holding eyelids open.

- Seek medical attention if irritation persists.

Ingestion

- Rinse mouth with water.

- Drink water or milkto dilute.

- Do NOT induce vomiting.

- Seek medical advice if large amounts are ingested (coating agents may have additional toxicity).

Firefighting Measures

- Non-flammable—does not support combustion.

- No special firefighting measures requiredfor calcium carbonate itself.

- Coating materials(e.g., stearic acid, silanes) may be combustible at high temperatures.

- If involved in a fire, use water spray, dry chemical, CO₂, or foamfor surrounding fires.

- Hazardous Decomposition: At very high temperatures (>800°C), decomposes into calcium oxide (quicklime) and CO₂ gas.

- Firefighters should wear SCBAin enclosed spaces due to potential CO₂ buildup

LABORATORY EQUIPMENT & APPARATUS

LABORATORY EQUIPMENT & APPARATUS

Fertilizers

Fertilizers Plant Growth Regulators

Plant Growth Regulators Soil Conditioners

Soil Conditioners Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Preservatives (baking)

Preservatives (baking)

Surfactants (cleaning)

Surfactants (cleaning) Builders

Builders Bleaching Agents

Bleaching Agents Enzymes

Enzymes Solvents (cleaning)

Solvents (cleaning) Fragrances

Fragrances