“Caustic Soda Micropearls” has been added to your cart. View cart

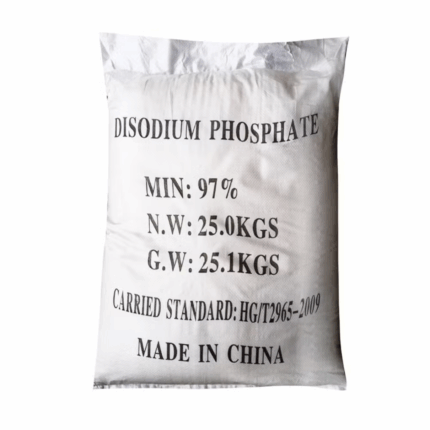

Disodium Phosphate

$ 2.00 Original price was: $ 2.00.$ 1.32Current price is: $ 1.32.

Glacial Acetic Acid Food Grade

$ 3.00 Original price was: $ 3.00.$ 2.17Current price is: $ 2.17.

Glacial Acetic Acid Tech grade

$ 3.00 Original price was: $ 3.00.$ 2.16Current price is: $ 2.16.

Whatsapp Order

Glacial Acetic Acid Tech grade is a clear, colorless liquid with a pungent vinegar-like odor. It is a less refined form of acetic acid primarily used for industrial and technical applications rather than food or pharmaceutical uses. Typically available in concentrations ranging from 80% to glacial (99-100%), it serves as a crucial chemical reagent, solvent, and intermediate in various industrial processes.

Description

Table of Contents

Toggle

Glacial Acetic Acid Tech grade

Primary Uses

- Chemical Manufacturing

-

-

- Key raw material for vinyl acetate monomer (VAM), used in adhesives, paints, and plastics.

- Production of acetic anhydride (for cellulose acetate in photographic films, textiles, and cigarette filters).

-

- Solvent & Cleaning Agent

-

-

- Used in printing, dyeing, and textile industries for degreasing and pH adjustment.

- Effective solvent for inks, resins, and pesticides.

-

- Rubber & Plastic Production

-

-

- Acts as a coagulant in latex processing for rubber gloves, tires, and seals.

- Used in polyester and PET plastic manufacturing.

-

- Pharmaceutical Intermediates

-

-

- Production of aspirin (acetylsalicylic acid), paracetamol, and antibiotics.

-

- Laboratory & Analytical Reagent

-

- Used in titrations, chemical synthesis, and buffer solutions.

Secondary Uses

- Oil & Gas Industry

-

-

- Well stimulation and acidizing to improve oil recovery.

- Removes calcium carbonate deposits in pipelines.

-

- Leather Tanning & Textiles

-

-

- Adjusts pH in leather processing and fabric dyeing.

- Helps in desizing and scouring cotton.

-

- Photography & Film Development

-

-

- Used in stop baths to neutralize alkaline developers.

-

- Wastewater Treatment

-

-

- Neutralizes alkaline wastewater in industrial plants.

-

- Wood Preservation & Paper Industry

-

- Prevents fungal growth in wood treatment.

- Used in paper pulping and coating processes.

KEY ATTRIBUTE

Basic Identification Attributes

- Chemical Name (IUPAC): Ethanoic acid

- Common/Trade Names:

- Technical-grade acetic acid

- Glacial acetic acid (if ≥99% purity)

- CAS Number: 64-19-7

- HS Code: 2915.21.00 (varies by country)

- Molecular Formula: C₂H₄O₂ (CH₃COOH)

- Synonyms:

- Methanecarboxylic acid

- Ethylic acid

2. Physical & Chemical Properties

- Physical State: Clear, colorless liquid (glacial form solidifies below 16.6°C)

- Color & Odor: Pungent vinegar-like odor; may appear slightly yellow if impure

- Melting Point: 16.6°C (61.9°F)

- Boiling Point: 118.1°C (244.6°F)

- Density: 1.049 g/cm³ (25°C)

- Solubility:

- Miscible in water, ethanol, ether

- pH Level: Strongly acidic (~2.4 at 1.0 M)

- Vapor Pressure: 15.7 mmHg (25°C)

- Flash Point: 39°C (102°F) (closed cup)

- Autoignition Temperature: 427°C (801°F)

- Viscosity: 1.22 mPa·s (25°C)

3. Safety & Hazard Attributes

- Hazard Class (GHS):

- Corrosive (Category 1B)

- Flammable (Category 3, for concentrations >80%)

- Skin/Eye Irritant (Category 1)

- NFPA Ratings:

- Health: 3 | Flammability: 2 | Reactivity: 0

- Exposure Limits:

- OSHA PEL: 10 ppm (25 mg/m³)

- ACGIH TLV: 10 ppm (25 mg/m³)

- Reactivity:

- Corrosive to metals (releases H₂ gas)

- Reacts violently with oxidizers (e.g., chromic acid, permanganates)

4. Storage & Handling Attributes

- Storage Conditions:

- Store in a cool, ventilated area (<25°C)

- Keep away from oxidizers and bases

- Use corrosion-resistant containers (HDPE, stainless steel 316)

- Incompatible Materials:

- Strong bases (e.g., NaOH), nitric acid, peroxides

- Container Type:

- HDPE drums or stainless steel tanks

- Avoid aluminum and copper

- Shelf Life: Indefinite if sealed (but may absorb moisture)

- Special Handling:

- Use nitrile gloves, goggles, and fume hood

- Ground containers to prevent static sparks

5. Regulatory & Compliance Attributes

- Regulatory Status:

- EPA: Listed as a hazardous substance (CERCLA)

- REACH: Registered

- DOT: UN 2789 (Class 8 – Corrosive)

- Hazard Symbols (GHS):

- Corrosion

- Flame (for concentrations >80%)

- Transportation Restrictions:

- UN Number: 2789

- Packing Group: II

- Waste Disposal:

- Neutralize with sodium bicarbonate before disposal

- EPA Hazardous Waste Code: D002 (corrosive)

6. Environmental & Health Impact

- Ecotoxicity:

- LC50 (fish): ~50–100 mg/L

- Readily biodegradable

- Persistence: Breaks down in air/water within days

- Carcinogenicity: Not classified (IARC/NTP)

- Biodegradability: >90% in 28 days (OECD 301B)

SAFETY HANDLING

1. Safety Precautions

Personal Protective Equipment (PPE)

- Gloves: Chemical-resistant (neoprene, nitrile, or PVC).

- Eye/Face Protection: Goggles + face shield (mandatory for concentrated acetic acid).

- Respiratory Protection: NIOSH-approved respirator (organic vapor cartridge) if ventilation is inadequate.

- Body Protection: Chemical-resistant apron or suit (for large spills/high concentrations).

Handling & Storage

- Ventilation: Use in a fume hood or well-ventilated area.

- Static Electricity Prevention: Ground and bond containers to avoid sparks.

- Incompatible Materials: Keep away from:

- Oxidizers (e.g., nitric acid, hydrogen peroxide) → violent reactions.

- Bases (e.g., sodium hydroxide) → exothermic neutralization.

- Metals (e.g., aluminum, zinc) → corrosion & hydrogen gas release.

- Storage:

- Sealed, corrosion-resistant containers (HDPE, stainless steel, or glass-lined tanks).

- Cool, dry, well-ventilated area away from sunlight and heat sources.

- Flammable storage cabinet (if ≥80% concentration).

Hygiene Measures

- No eating, drinking, or smoking in handling areas.

- Emergency shower & eyewash station must be accessible.

- Wash hands thoroughly after handling.

2. First Aid Measures

Inhalation (Vapors/Fumes)

- Move to fresh air immediately.

- If breathing is difficult, administer oxygen and seek medical help.

- If unconscious, perform CPR (if trained) and call emergency services.

Skin Contact

- Remove contaminated clothing immediately.

- Rinse with plenty of water for ≥15 minutes.

- Apply soap to remove residual acid.

- Seek medical attention if burns or irritation persist.

Eye Contact

- Immediately flush eyes with water for ≥15 minutes (hold eyelids open).

- Do NOT rub eyes.

- Seek emergency medical care (risk of corneal damage).

Ingestion

- Do NOT induce vomiting (risk of esophageal burns).

- Rinse mouth with water.

- Drink milk or water to dilute (if conscious).

- Seek immediate medical attention.

3. Firefighting Measures

Fire Hazards

- Highly flammable (≥80% concentration, flash point 39°C / 102°F).

- Vapors can form explosive mixtures with air.

- Decomposes at high temps, releasing flammable gases (CO, CO₂).

Extinguishing Media

✔ Alcohol-resistant foam

✔ CO₂

✔ Dry chemical powder

✔ Water spray (to cool containers, not direct jet—may spread flames).

Firefighting Precautions

- Wear SCBA (self-contained breathing apparatus) and full protective gear.

- Evacuate area—vapors travel and can ignite.

- Cool nearby containers with water spray to prevent explosion.

- Do NOT extinguish flames unless leak is stopped (risk of re-ignition).

4. Spill & Leak Control

- Small Spills:

- Neutralize with sodium bicarbonate (baking soda) or calcium carbonate.

- Absorb with inert material (vermiculite, sand).

- Dispose as hazardous waste.

- Large Spills:

- Evacuate area.

- Use acid-resistant PPE.

- Contain spill with barriers (clay, sandbags).

- Ventilate area to disperse vapors.

Related products

Bentonite Powder

Bentonite powder is a naturally occurring absorbent clay primarily composed of montmorillonite, a type of smectite clay mineral. It exhibits excellent swelling and water absorption properties, making it highly versatile in industrial and commercial applications. Bentonite forms a gel-like substance when mixed with water, which imparts viscosity and plasticity. It is used extensively for its binding, sealing, and adsorptive characteristics. Its fine powder form allows for easy incorporation in various processes including drilling, foundry, cosmetics, pharmaceuticals, and agriculture.

Borax Decahydrate

Borax Decahydrate, also known as sodium tetraborate decahydrate, is a naturally occurring mineral and an important inorganic compound. It appears as colorless or white crystalline granules or powder with a salty, alkaline taste. This compound is widely used in detergents, cosmetics, glass manufacturing, agriculture, and various industrial applications due to its excellent buffering, emulsifying, and antiseptic properties. The “decahydrate” indicates that each molecule of borax contains ten water molecules bound in its crystal structure, contributing to its crystalline appearance and physical properties.

Caustic Soda Flakes

Caustic Soda Flakes, also known as Sodium Hydroxide Flakes (NaOH), are a highly alkaline, white, solid substance that is crystalline and flaky in form. Produced by evaporating aqueous sodium hydroxide solutions, these flakes are highly soluble in water and exhibit strong corrosive properties. Caustic Soda Flakes are widely used in a variety of industrial, chemical, and manufacturing processes due to their strong alkalinity, ability to saponify fats, and effectiveness in pH adjustment. Their high purity and ease of handling in flake form make them suitable for use in chemical synthesis, pulp and paper production, water treatment, and detergent manufacturing.

Citric Acid Monohydrate

Citric Acid Monohydrate is a white, crystalline powder or granule form of citric acid containing one molecule of water per molecule of acid. It is a natural organic acid commonly derived from citrus fruits or produced by fermentation processes. Citric Acid Monohydrate is widely used as an acidulant, preservative, and chelating agent in various industries. Compared to the anhydrous form, it has a slightly lower acid concentration due to the water molecule but offers excellent solubility and stability. It is prized for its sour flavor, buffering capacity, and ability to bind metal ions, making it indispensable in food, pharmaceutical, cosmetic, and industrial applications.

Dipotassium Hydrogen Phosphate

Dipotassium Hydrogen Phosphate (also known as dipotassium phosphate, DKP) is an inorganic salt used widely as a buffering agent, emulsifier, and nutritional supplement in various industries. It is a white, crystalline, highly water-soluble powder with alkaline properties. DKP plays a vital role in food processing, pharmaceuticals, water treatment, and agriculture due to its ability to stabilize pH, improve texture, and supply essential potassium and phosphate ions.

Disodium Hydrogen Phosphate Dihydrate (Na₂HPO₄·2H₂O)

Disodium Hydrogen Phosphate Dihydrate is the hydrated form of disodium hydrogen phosphate, a white crystalline powder commonly used as a buffering agent, emulsifier, and sequestrant. The dihydrate form contains two water molecules per formula unit, which affects its physical properties such as melting point and solubility. It is widely applied in food, pharmaceutical, water treatment, and industrial processes to maintain pH stability, improve texture, and supply essential sodium and phosphate ions.

Industrial Salt

Industrial Salt, chemically known as Sodium Chloride (NaCl), is a high-purity crystalline compound widely used across industrial, chemical, agricultural, and water treatment applications. It appears as white to off-white crystalline granules or powder, depending on the grade and particle size. Industrial Salt is an essential raw material in numerous chemical processes, including chlor-alkali production, de-icing, textile dyeing, and water softening. Its versatility and cost-effectiveness make it indispensable in large-scale operations.

Magnesium Carbonate Light

Magnesium Carbonate Light is a fine, white, odorless powder primarily composed of magnesium carbonate (MgCO₃). It is characterized by its light texture and high purity. This mineral compound is widely used across various industries due to its excellent absorption properties, mild alkalinity, and non-toxic nature. Magnesium Carbonate Light is commonly employed as an antacid, drying agent, filler, and flow aid in food, pharmaceutical, cosmetic, and industrial applications.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders