“Calcium Carbonate Light” has been added to your cart. View cart

Master Flow

Whatsapp Order

Master Flow is a high-performance concrete plasticizer and superplasticizer designed to improve the workability and flow of concrete mixtures without increasing water content. It enhances concrete slump, making placement and compaction easier, especially in large pours or complex formworks. Master Flow promotes better dispersion of cement particles, leading to improved strength development, reduced bleeding, and increased durability. It is widely used in ready-mix concrete, precast elements, and infrastructure projects to achieve superior surface finish and mechanical properties.

Category: Admixtures

Tags: Construction chemical, MasterFlow, Precision grout, Structural anchoring, Structural grout

Description

Table of Contents

Toggle

Master Flow

Primary Uses

- Concrete Workability Enhancement

Improves flow and slump of concrete mixtures for easier placement and compaction. - Water Reduction

Allows reduction in water content while maintaining workability, leading to higher strength and durability. - High-Performance Concrete

Used in producing high-strength and high-performance concrete for structural and architectural applications.

Secondary Uses

- Self-Leveling Concrete

Facilitates the production of self-leveling or self-compacting concrete mixes. - Precast and Ready-Mix Concrete

Enhances consistency and quality in precast and ready-mix concrete manufacturing. - Shotcrete

Improves pumpability and adhesion in sprayed concrete applications.

PRODUCT KEY FEATURES

- Basic Identification Attributes

- Chemical Name (IUPAC): Polycarboxylate ether-based superplasticizer (or specific polymeric compound depending on grade)

- Common/Trade Name: Master Flow

- CAS Number: Not applicable (commercial mixture)

- HS Code: 3824.90.00 (Other chemical products and preparations)

- Synonyms: Concrete superplasticizer; concrete plasticizer; polycarboxylate ether (PCE) admixture

- Physical & Chemical Properties

- Physical State: Liquid

- Color & Odor: Light amber to brown; mild characteristic odor

- pH: Approximately 4–7 (depending on formulation)

- Solubility: Miscible with water

- Density: Approx. 1.05–1.15 g/cm³

- Stability: Stable under recommended storage conditions

- Safety & Hazard Attributes

- GHS Classification: Not classified as hazardous under normal use

- Toxicity: Low toxicity; avoid prolonged skin contact

- Exposure Limits: No specific occupational limits; use standard industrial hygiene practices

- Storage & Handling Attributes

- Storage Conditions: Store in cool, dry place away from direct sunlight and freezing temperatures

- Container Type: Supplied in sealed plastic drums or containers

- Shelf Life: Typically 6 to 12 months if stored properly

- Handling Precautions: Use gloves and eye protection; avoid inhalation and prolonged skin contact

- Regulatory & Compliance Attributes

- Complies with relevant construction chemical regulations and standards

- Free from heavy metals and environmentally harmful substances

- Environmental & Health Impact

- Biodegradability: Biodegradable under aerobic conditions

- Ecotoxicity: Low aquatic toxicity at recommended dosages

- Bioaccumulation: Not significant

- Carcinogenicity/Mutagenicity: Not classified as hazardous

SAFETY HANDLING PRECAUTIONS

- Safety Handling Precautions

- PPE Required: Gloves, safety goggles recommended during handling

- Handling Guidelines: Use in well-ventilated areas; avoid skin and eye contact

- Storage Measures: Keep container tightly closed; avoid freezing and heat exposure

- First Aid Measures

- Inhalation: Move to fresh air if irritation occurs

- Skin Contact: Wash thoroughly with soap and water

- Eye Contact: Rinse immediately with plenty of water; seek medical attention if irritation persists

- Ingestion: Rinse mouth; seek medical advice if discomfort occurs

- Firefighting Measures

- Fire Hazards: Non-flammable liquid; use caution around electrical equipment

- Extinguishing Media: Use water spray, foam, or dry chemical extinguishers if surrounding materials catch fire

- Special Precautions: Wear protective equipment and self-contained breathing apparatus if necessary

- Hazardous Combustion Products: May emit carbon oxides and other toxic fumes on decomposition

Related products

Bondex 5299

Bondex 5299 is a solvent-based, high-performance industrial adhesive formulated to provide strong, durable bonds on a wide variety of substrates such as metals, plastics, rubber, and composites. It appears as a clear to amber viscous liquid with a characteristic solvent odor. Known for excellent resistance to heat, moisture, and chemicals, Bondex 5299 cures by solvent evaporation to form a flexible, resilient bond. It is widely used in automotive, aerospace, electronics, and heavy machinery industries due to its reliable bonding strength and quick curing properties.

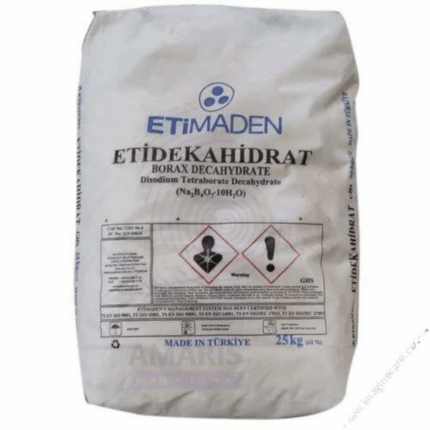

Borax Decahydrate

Borax Decahydrate, also known as sodium tetraborate decahydrate, is a naturally occurring mineral and an important inorganic compound. It appears as colorless or white crystalline granules or powder with a salty, alkaline taste. This compound is widely used in detergents, cosmetics, glass manufacturing, agriculture, and various industrial applications due to its excellent buffering, emulsifying, and antiseptic properties. The “decahydrate” indicates that each molecule of borax contains ten water molecules bound in its crystal structure, contributing to its crystalline appearance and physical properties.

Calcium Carbonate Uncoated

Calcium Carbonate Uncoated is a naturally occurring mineral compound composed primarily of calcium, carbon, and oxygen with the chemical formula CaCO₃. It appears as a fine white powder or granules, widely used as a filler, pigment, and functional additive across various industries. The uncoated form means the calcium carbonate particles are not surface-treated, retaining their natural properties. It is valued for its high brightness, whiteness, and excellent compressibility. Uncoated calcium carbonate is used to enhance opacity, improve processing, and reduce costs in plastics, paints, coatings, adhesives, rubber, paper, and construction materials.

Caustic Soda Flakes

Caustic Soda Flakes, also known as Sodium Hydroxide Flakes (NaOH), are a highly alkaline, white, solid substance that is crystalline and flaky in form. Produced by evaporating aqueous sodium hydroxide solutions, these flakes are highly soluble in water and exhibit strong corrosive properties. Caustic Soda Flakes are widely used in a variety of industrial, chemical, and manufacturing processes due to their strong alkalinity, ability to saponify fats, and effectiveness in pH adjustment. Their high purity and ease of handling in flake form make them suitable for use in chemical synthesis, pulp and paper production, water treatment, and detergent manufacturing.

Caustic Soda Micropearls

Caustic Soda Micropearls are small, spherical, solid particles of sodium hydroxide (NaOH) produced through specialized prilling or pelletizing techniques. They offer excellent flowability, high purity, and uniform size distribution, making them ideal for precise dosing and handling in industrial and chemical processes. The micropearls form is preferred in applications where dust control, ease of transport, and controlled dissolution rates are critical. Caustic Soda Micropearls exhibit strong alkalinity, are highly soluble in water with an exothermic reaction, and are widely used across many sectors including chemical manufacturing, water treatment, pulp and paper processing, and detergent production.

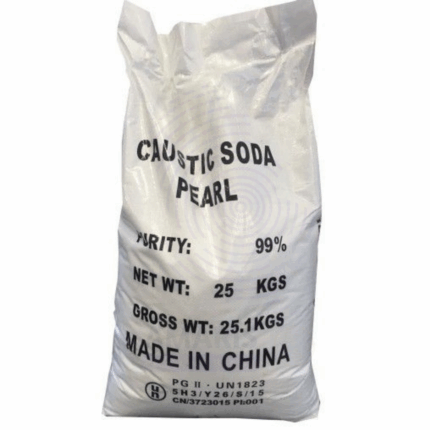

Caustic Soda Pearls

Caustic Soda Pearls are small, solid, spherical particles of sodium hydroxide (NaOH) produced by a controlled cooling and solidification process. These pearls offer superior flowability, uniform size distribution, and reduced dust generation compared to flake or powder forms. They are highly soluble in water, exhibiting a strong alkaline nature with vigorous exothermic dissolution. Caustic Soda Pearls are widely used across industries including chemical manufacturing, water treatment, pulp and paper processing, and detergents due to their purity, ease of handling, and efficient dissolution characteristics.

Corn Starch Industrial Grade

Corn Starch Industrial Grade is a finely milled, white powder derived from the endosperm of maize (Zea mays). Unlike food-grade starch, industrial grade is tailored for non-food applications where its thickening, adhesive, and film-forming properties are exploited. It consists primarily of amylose and amylopectin polysaccharides and is valued for its biodegradability, renewability, and cost-effectiveness. Industrial corn starch is used extensively as a raw material or functional additive across a wide variety of manufacturing processes, including paper, textiles, adhesives, and packaging industries.

Lactic Acid

Lactic Acid is a colorless to pale yellow, viscous liquid with a mild acidic odor. It is an organic acid naturally produced by fermentation and widely used in industrial, pharmaceutical, cosmetic, and food applications. The 80% concentration provides a balance of potency and ease of handling, making it suitable for pH adjustment, preservation, and chemical synthesis. Lactic acid is biodegradable, non-toxic, and valued for its multifunctionality including antimicrobial properties and chelation abilities.

Acidulants

Acidulants Antioxidants

Antioxidants Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food)

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders