Silicon Emulsion

Whatsapp Order

Silicon Emulsion is a stable, water-based emulsion of polydimethylsiloxane (PDMS) or other silicone fluids, commonly used for lubrication, gloss enhancement, release, water repellency, and surface conditioning. It appears as a milky-white, viscous liquid and is non-toxic, non-flammable, and easy to handle. Due to its excellent spreadability and low surface tension, it is widely used in industries ranging from automotive and textiles to agriculture, construction, and cosmetics.

Categories: Lubricants, Softening Agents

Tags: Non-Ionic Emulsion, Silicon Emulsion, Silicone Oil Emulsion, Water-Based Silicone

Description

Table of Contents

Toggle

Silicon Emulsion

Primary Uses

- Textile Industry

- Used as a softening agent for fabrics and yarns, imparting smoothness and a silky finish.

- Enhances wrinkle resistance and reduces static cling in synthetic fibers.

- Improves fabric lubrication during weaving and knitting processes.

- Automotive Industry

- Used as a dashboard and tire dressing for gloss enhancement and UV protection.

- Functions as a lubricant and protectant for rubber, vinyl, and plastic components.

- Used in car polishes and detailing sprays for shine and water resistance.

- Plastic & Rubber Processing

- Serves as a mold release agent in plastic and rubber molding operations.

- Provides surface gloss and anti-stick properties in rubber sheet manufacturing.

- Acts as a processing aid to improve flow and prevent material adhesion.

- Construction & Building Materials

- Used in concrete formwork as a release agent to prevent sticking and reduce surface defects.

- Provides water repellency in construction materials like bricks, tiles, and cementitious substrates.

- Used in coatings and sealants to enhance durability and water resistance.

- Personal Care & Cosmetics

- Included in hair care products for smoothness, detangling, and shine enhancement.

- Used in skin creams and lotions for conditioning and spreadability.

- Functions as a non-greasy emollient in sunscreens, serums, and shaving products.

- Furniture & Wood Polish

- Used in polishes for wood, leather, and synthetic furniture for shine and dust repellence.

- Protects surfaces from watermarks and minor abrasions.

Secondary Uses

- Agriculture

- Acts as a spray adjuvant to improve the spread and absorption of agrochemicals on plant surfaces.

- Used to reduce surface tension and improve pesticide efficacy.

- Paper & Packaging Industry

- Provides anti-blocking and anti-stick properties to packaging films and paper.

- Used in release coatings for label backings and adhesive tapes.

- Leather Processing

- Imparts softness, gloss, and water repellency to finished leather goods.

- Metalworking

- Used as a lubricant and anti-corrosion coating in light-duty metal forming operations.

- Printing Industry

- Applied as a release and anti-foaming agent in ink formulations and printing machinery.

- Household & Industrial Cleaning Products

- Added to surface cleaners and polishes for shine enhancement and protective coating.

KEY PRODUCT FEATURES

1. Basic Identification Attributes

- Chemical Name (IUPAC): Polydimethylsiloxane emulsion (composition may vary)

- Common/Trade Name: Silicon Emulsion

- CAS Number: Varies (e.g., 63148-62-9 for PDMS)

- HS Code: 3910.00.00

- Synonyms: Silicone fluid emulsion, PDMS emulsion, Silicone oil in water

2. Physical & Chemical Properties

- Physical State: Milky liquid emulsion

- Color & Odor: White or off-white; slight odor

- Solubility: Dispersible in water

- pH: Typically 6–8

- Viscosity: Varies (typically 100–1000 cSt based on formulation)

- Solid Content: Typically 20%–60% silicone

- Stability: Stable under normal temperature and storage conditions

3. Safety & Hazard Attributes

- GHS Classification: Not classified as hazardous (varies by formulation)

- Toxicity: Low; generally considered non-toxic and non-sensitizing

- Exposure Limits: No specific occupational exposure limits under normal use

- Inhalation of aerosols should be avoided

4. Storage & Handling Attributes

- Storage Conditions: Store in cool, dry conditions away from direct sunlight and freezing temperatures

- Container Type: Supplied in plastic drums, pails, or IBCs (typically 25kg, 50kg, 200kg)

- Shelf Life: Typically 6–12 months if stored properly

- Handling Precautions: Avoid contact with eyes; do not freeze; agitate gently before use

5. Regulatory & Compliance Attributes

- Complies with relevant industrial and cosmetic safety standards (e.g., REACH, RoHS, FDA-approved grades available for indirect food contact)

- May meet NSF standards for incidental food contact in some formulations

- Manufactured under ISO or GMP conditions depending on intended use

- VOC compliant where applicable in coatings and automotive uses

6. Environmental & Health Impact

- Biodegradability: Poor in natural environments (depends on silicone polymer type)

- Ecotoxicity: Generally low; avoid release into aquatic environments

- Bioaccumulation: Low potential

- Environmental Impact: Minimal when used and disposed of properly; non-ozone depleting

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

- PPE Required: Safety goggles, gloves, and protective clothing recommended

- Handling Guidelines: Use in well-ventilated areas; avoid prolonged inhalation or contact with eyes

- Storage Measures: Keep containers tightly closed and stored in a dry environment

First Aid Measures

- Inhalation: Move to fresh air; seek medical advice if respiratory symptoms occur

- Skin Contact: Wash with soap and water; seek help if irritation develops

- Eye Contact: Rinse with clean water for 15 minutes; get medical attention if irritation persists

- Ingestion: Rinse mouth with water; do not induce vomiting; seek medical assistance

Firefighting Measures

- Fire Hazards: Generally non-flammable; may burn at high temperatures

- Extinguishing Media: Use water spray, foam, dry chemical, or CO₂

- Special Precautions: Use self-contained breathing apparatus if burning silicone residue is present

- Hazardous Combustion Products: Silicon oxides, carbon oxides, and formaldehyde (if overheated)

Related products

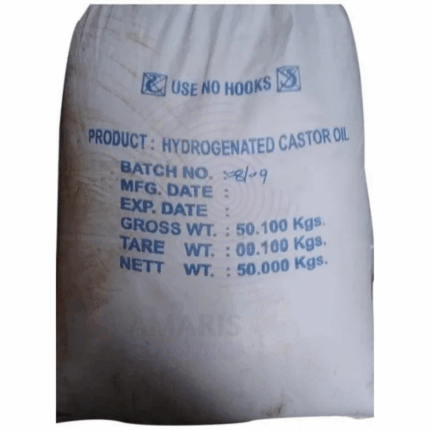

Hydrogenated Castor Oil

Hydrogenated Castor Oil, also known as castor wax, is a hard, brittle, and high-melting-point wax derived by the hydrogenation of pure castor oil. This white to off-white, odorless substance is non-toxic and insoluble in water but dispersible in surfactant systems. Its primary component is hydrogenated ricinoleic acid triglyceride, and it is prized for its excellent lubricating, emulsifying, thickening, and consistency-enhancing properties.

Due to its stability, non-reactivity, and film-forming capability, Hydrogenated Castor Oil is widely used in cosmetics, personal care, pharmaceuticals, industrial lubricants, coatings, plastics, and more. It improves product texture, enhances emulsion stability, and provides moisture retention in skincare applications.

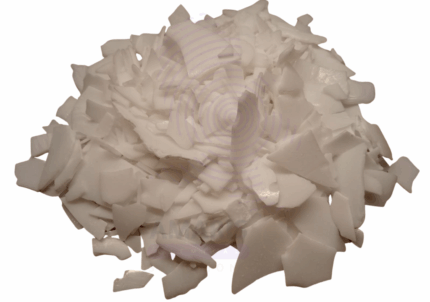

Inosoft( Softener Flakes)

Inosoft Softener Flakes is a solid, flaked fabric softener designed for use in textile finishing processes. These flakes are typically composed of cationic softening agents derived from quaternary ammonium compounds or fatty amine derivatives, formulated to impart softness, smoothness, and antistatic properties to fabrics. The flaked form allows for easy storage, handling, and controlled dosing in industrial textile softening applications. Inosoft flakes dissolve readily in water during processing to provide uniform softening and enhanced fabric feel.

Light White Mineral Oil Tech Grade

Light White Mineral Oil Tech Grade is a highly refined, colorless, odorless, and tasteless petroleum-derived oil. It is characterized by its low viscosity and excellent lubricating properties. This technical-grade mineral oil undergoes stringent purification processes to remove impurities, making it suitable for various industrial, cosmetic, pharmaceutical, and food-related applications. Its chemical stability, non-reactivity, and safety profile make it a versatile ingredient and lubricant in many manufacturing and processing sectors.

Polyvinyl Chloride PE Wax

Polyvinyl Chloride PE Wax is a polyethylene-based wax additive used in PVC formulations to improve processing, lubrication, and surface finish. It serves as an internal and external lubricant in both rigid and flexible PVC products, enhancing extrusion, molding, and calendaring operations. It also contributes to better dispersion of fillers and pigments, reduced friction, and improved thermal stability. PE Wax for PVC is available in powder, flake, or granule form and is valued for its compatibility, thermal resistance, and cost-effectiveness.

Renisco KCS 68

Renisco KCS 68 is a clay-coated, controlled-release potassium sulfate fertilizer granule containing approximately 68% K₂O equivalent. The clay coating regulates potassium release, aligning nutrient availability with plant uptake over an extended period. This minimizes leaching and enhances nutrient-use efficiency. Renisco KCS 68 is widely used in horticulture, agriculture, turf management, and specialty crop production.

Titan Power 40 SAE

Titan Power 40 SAE is a high-performance monograde engine oil formulated for diesel and gasoline engines operating under moderate to severe conditions. Classified as SAE 40 by the Society of Automotive Engineers, this oil offers excellent thermal stability, wear protection, and oxidation resistance. It is particularly suited for older-generation engines and equipment in on-road, off-road, industrial, and marine environments where SAE 40 is specified. The formulation ensures reliable lubrication, engine cleanliness, and extended engine life.

White Oil

White Oil, also known as Mineral Oil or Liquid Paraffin, is a highly refined, clear, odorless, and tasteless petroleum-derived oil. It is composed of saturated aliphatic hydrocarbons and is available in various viscosity grades depending on the intended application. The product is extensively purified to remove aromatic hydrocarbons, sulfur compounds, and other impurities, making it suitable for use in personal care, pharmaceutical, food, and industrial applications. White Oil is prized for its excellent lubricity, moisture barrier function, chemical stability, and non-comedogenic properties.

White Oil supplied in a 162 kg drum format is typically used in bulk manufacturing and industrial-scale processing across multiple sectors.

Zinc Stearate

Zinc Stearate is a fine, white powder composed of zinc salts of stearic acid. It is a hydrophobic, non-toxic metal soap widely used as a lubricant, release agent, and stabilizer in plastics, rubber, paints, coatings, and personal care industries. Known for its excellent mold-release properties and compatibility with a range of polymers, Zinc Stearate offers thermal stability and processing efficiency across industrial applications.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders