Fillers and reinforcements are additives used to improve the strength, durability, and cost-effectiveness of plastics and composites. Fillers like calcium carbonate or talc reduce material costs while enhancing properties like stiffness, while reinforcements such as glass or carbon fibers significantly boost mechanical strength and heat resistance. These additives enable tailored performance for applications ranging from everyday packaging to high-tech aerospace components.

Calcium Carbonate Uncoated

Calcium Carbonate Uncoated is a naturally occurring mineral compound composed primarily of calcium, carbon, and oxygen with the chemical formula CaCO₃. It appears as a fine white powder or granules, widely used as a filler, pigment, and functional additive across various industries. The uncoated form means the calcium carbonate particles are not surface-treated, retaining their natural properties. It is valued for its high brightness, whiteness, and excellent compressibility. Uncoated calcium carbonate is used to enhance opacity, improve processing, and reduce costs in plastics, paints, coatings, adhesives, rubber, paper, and construction materials.

Dimethicone Silicon Oil

Dimethicone Silicon Oil, also known as polydimethylsiloxane (PDMS) or silicone oil, is a clear, odorless, and non-volatile silicone-based polymer widely used for its lubricating, anti-foaming, water-repellent, and skin-conditioning properties. It is a linear silicone polymer composed of repeating dimethylsiloxane units. Dimethicone exhibits excellent thermal stability, chemical inertness, and low surface tension, making it highly versatile in pharmaceutical, cosmetic, personal care, industrial, and food applications. It is available in various viscosities, from very low to high viscosity oils, enabling tailored formulations.

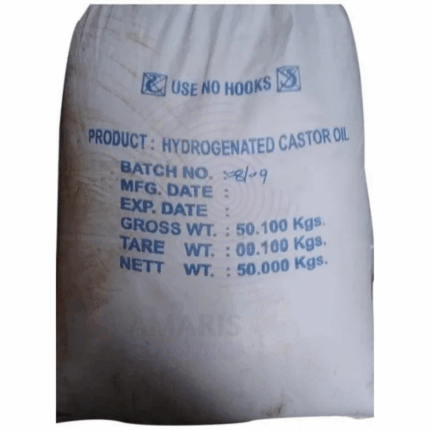

Hydrogenated Castor Oil

Hydrogenated Castor Oil, also known as castor wax, is a hard, brittle, and high-melting-point wax derived by the hydrogenation of pure castor oil. This white to off-white, odorless substance is non-toxic and insoluble in water but dispersible in surfactant systems. Its primary component is hydrogenated ricinoleic acid triglyceride, and it is prized for its excellent lubricating, emulsifying, thickening, and consistency-enhancing properties.

Due to its stability, non-reactivity, and film-forming capability, Hydrogenated Castor Oil is widely used in cosmetics, personal care, pharmaceuticals, industrial lubricants, coatings, plastics, and more. It improves product texture, enhances emulsion stability, and provides moisture retention in skincare applications.

Melamine

Melamine is an organic compound widely used as a raw material in the production of melamine-formaldehyde resins, laminates, adhesives, coatings, and flame retardants. It offers excellent hardness, thermal stability, and chemical resistance. Supplied in 25kg bags, melamine is a white crystalline powder with high nitrogen content, making it a valuable additive in plastics, construction materials, and surface treatments.

Styrene Acrylic

Styrene Acrylic is a copolymer emulsion combining styrene and acrylic monomers, widely used as a versatile binder in coatings, adhesives, and construction materials. It offers excellent film-forming properties, adhesion, water resistance, and durability. This product enhances the performance and longevity of paints, sealants, textiles, and paper coatings, with flexibility for both indoor and outdoor applications. Styrene Acrylic emulsions are designed to meet stringent industrial and environmental standards.

Styrene Acrylic Emulsion Polymer

Styrene Acrylic Emulsion Polymer is a water-based copolymer emulsion combining styrene and acrylic monomers, designed as a versatile binder with excellent film formation, adhesion, and durability. Widely used across paints, coatings, adhesives, textiles, and construction materials, this polymer offers superior weather resistance, water repellency, and flexibility. Its emulsified form enables easy incorporation into aqueous formulations, delivering enhanced performance and environmental benefits by reducing VOC emissions.

Styrene Polymer Copolymer (230kg)

Styrene Polymer Copolymer is a high-performance copolymer consisting primarily of styrene combined with other monomers such as acrylonitrile or butadiene, designed to offer enhanced mechanical properties, chemical resistance, and processability. Supplied in bulk packaging of 230kg, it is widely used in plastics, adhesives, coatings, and rubber industries. This copolymer provides excellent toughness, thermal stability, and versatility, making it suitable for demanding industrial applications.

Whiting

Whiting is a finely ground, white, chalky substance primarily composed of calcium carbonate (CaCO₃). It is widely used as a pigment, filler, and extender in various industrial and commercial applications. Whiting provides opacity, brightness, and smoothness to products, enhancing their appearance and physical properties. Its natural abundance and versatility make it an economical additive in multiple manufacturing processes.

Xysil 200 Fumed Silica 200

Xysil 200 Fumed Silica 200 is a high-purity fumed silica produced through flame hydrolysis of silicon tetrachloride. It is an ultra-fine, amorphous, white powder with a very high surface area and low bulk density. Xysil 200 is widely used as a reinforcing filler, thickening agent, anti-caking agent, and rheology modifier in various industrial applications. Its unique physical properties improve the mechanical strength, viscosity, and stability of formulated products.

Acidulants

Acidulants Antioxidants

Antioxidants Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food)

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders