“Carnauba Wax” has been added to your cart. View cart

Ammonia solutions 33kg 33%conc

$7,500.00 Original price was: $7,500.00.$6,000.00Current price is: $6,000.00.

Calcium Octoate 10%

$90,000.00 Original price was: $90,000.00.$89,000.00Current price is: $89,000.00.

Bondex 5299

$8,500.00 Original price was: $8,500.00.$8,400.00Current price is: $8,400.00.

Whatsapp Order

Bondex 5299 is a fast-drying, solvent-based bitumen primer used to prepare and seal surfaces (concrete, metal, masonry) before applying waterproofing membranes or coatings. It enhances adhesion, prevents moisture damage, and protects against corrosion—ideal for roofing, foundations, pipelines, and repairs.

- Key Features:

✔ Penetrates pores for strong bonding

✔ Compatible with bitumen membranes & mastics

✔ Quick-drying (1–4 hours)

SKU:

ACS91668CHEM0

Categories: Sealants and Adhesives, Concrete Repair Chemicals, Sealants and Adhesives, Waterproofing Agents

Tags: bondex, waterproofing

Description

BONDEX 5299 USES

Surface Preparation

- Seals porous substrates(concrete, masonry, metal) to create a uniform, adhesive-friendly surface.

- Enhances bondingfor bituminous membranes, self-adhesive tapes, and liquid-applied coatings.

Waterproofing

- Roofing:Prepares decks for APP/SBS membranes or torch-on systems.

- Basements/Foundations:Prevents moisture penetration in below-ground structures.

- Bridges/Tunnels:Used in civil engineering for moisture protection.

Corrosion Protection

- Metal Pipes & Tanks:Acts as a primer before bitumen wrapping to inhibit rust.

Repair & Maintenance

- Prepares damaged surfaces (cracks, old bitumen layers) for patching or recoating.

Additional information

| AVAILABLE PACK SIZE |

250kg ( Metal or Plastic drum) |

|---|

Reviews (0)

Be the first to review “Bondex 5299” Cancel reply

KEY ATTRIBUTES

1. Basic Identification Attributes

- Chemical Name: Polyurethane-based adhesive/sealant (exact composition proprietary)

- CAS Number: Proprietary blend (no single CAS; base polymers may include 63148-65-2 for polyurethanes)

- HS Code: 3506.91.00 (Polyurethane-based adhesives)

- Molecular Formula: Not applicable (complex polymer blend)

- Synonyms: PU adhesive, Construction sealant, Elastic bonding adhesive

2. Physical & Chemical Properties

- Physical State: Paste/liquid (cures to elastomeric solid)

- Color: Typically white, gray, or black (varies by formulation)

- Odor: Mild solvent/polymer odor (depends on VOC content)

- Boiling Point: N/A (cures chemically)

- Melting Point: N/A (thermoset polymer)

- Density: ~1.1–1.3 g/cm³ (uncured)

- Solubility:

- Water: Insoluble (once cured)

- Organic Solvents: Swells in acetone/toluene (pre-cure)

- pH Level: Neutral (~6–8)

- Vapor Pressure: Low (solvent-free formulations)

- Flash Point: >100°C (non-flammable if solvent-free)

- Cure Time: 24–72 hours (depends on humidity/temperature)

- Shore Hardness: ~30A–50A (after curing)

3. Safety & Hazard Attributes

- Hazard Class (GHS):

- Low hazard(may include H315/H319: Skin/eye irritation)

- Isocyanate-free formulations: Reduced reactivity

- NFPA Ratings: Health: 1 | Flammability: 1 | Reactivity: 0

- Exposure Limits:

- Isocyanates (if present): 0.005 ppm (OSHA PEL)

- VOCs: <50 g/L (for low-VOC formulations)

- Reactivity:

- Moisture-curing (reacts with humidity).

- Incompatible with strong acids/bases before curing.

4. Storage & Handling Attributes

- Storage Conditions:

- Temperature: 5–25°C (avoid freezing)

- Humidity: Keep containers sealed (prevents premature curing)

- Incompatible Materials: Wet surfaces, amines, acids (pre-cure)

- Container Type: Airtight cartridges or buckets (aluminum/plastic)

- Shelf Life: 12–18 months (unopened, stored properly)

- Special Handling:

- PPE: Nitrile gloves, eye protection.

- Ventilation: Required for confined spaces.

5. Regulatory & Compliance Attributes

- Regulatory Status:

- EU REACH: Compliant for isocyanates (if present).

- VOC Compliance: Meets EPA/DIR 2014/312/EU limits.

- FDA: Not food-contact approved (unless specified).

- Hazard Symbols:

- GHS07(Exclamation mark for irritation) if applicable.

- Transportation Restrictions: Non-hazardous (no UN number for solvent-free).

- Waste Disposal: Cured material as solid waste; uncured as hazardous waste (local regulations apply).

6. Environmental & Health Impact

- Ecotoxicity: Low post-cure; uncured material may harm aquatic life.

- Persistence: Cured polymer inert; microplastic concerns if abraded.

- Carcinogenicity:

- Isocyanates (if present): Potential sensitizer (IARC Group 2B).

- Solvents: Limited (low-VOC formulations).

- Biodegradability: Non-biodegradable (synthetic polymer)

SAFETY PRECAUTIONS

Personal Protective Equipment (PPE)

- Respiratory Protection:Use an organic vapor respirator (if ventilation is poor).

- Eye Protection:Wear chemical-resistant goggles or a face shield.

- Skin Protection:Use nitrile or neoprene gloves and long-sleeved clothing.

- Foot Protection:Wear steel-toe boots to prevent spills on feet.

Handling & Storage

- Store in a cool, dry, well-ventilated areaaway from heat, sparks, and open flames.

- Keep containers tightly closedwhen not in use.

- Use non-sparking toolsto prevent ignition.

- Ground containersduring transfer to avoid static electricity buildup.

- Avoid skin contactand breathing in vapors.

Ventilation

- Use in open-air or well-ventilated spaces.

- If working indoors, use mechanical ventilation (fume extraction).

Spill & Leak Control

- Small spills:Absorb with sand, vermiculite, or oil absorbent pads.

- Large spills:Contain with barriers and prevent entry into drains or waterways.

- Dispose of waste as hazardous materialper local regulations.

Inhalation (Fumes Exposure)

- Move to fresh air immediately.

- If breathing is difficult, provide oxygenand seek medical attention.

Skin Contact

- Remove contaminated clothing.

- Wash affected area with soap and water(do not use solvents).

- If irritation persists, seek medical help.

Eye Contact

- Rinse eyes with lukewarm water for 15+ minutes, holding eyelids open.

- Seek immediate medical attention.

Ingestion (Swallowing)

- Do NOT induce vomiting.

- Rinse mouth with water and seek emergency medical help.

Bondex 5299 is highly flammable due to solvent content.

Suitable Extinguishing Media

- Dry chemical powder (ABC type)

- Carbon dioxide (CO₂)

- Foam(for large fires)

- Water spray(to cool containers, not direct jets)

Unsuitable Extinguishing Media

- Avoid water jets(may spread fire).

Firefighter Precautions

- Wear self-contained breathing apparatus (SCBA)and full protective gear.

- Cool nearby containers with water sprayto prevent explosion.

- Toxic fumes (CO, SO₂, etc.) may be released—ensure proper ventilation.

Special Hazards

- Risk of flashback(vapors can travel and ignite).

- Fire may reignite even after being extinguished

Related products

Bentonite Powder

Bentonite powder is a naturally occurring, highly absorbent clay-like substance derived from volcanic ash. It is composed primarily of montmorillonite, a mineral that is known for its ability to absorb water and other liquids. Bentonite powder is commonly used in a variety of industries, including construction, drilling, and cosmetics, due to its unique properties such as its ability to swell and form a gel-like substance when it comes into contact with water, making it useful as a binding, thickening, and clarifying agent.

Bitumen Primer

Bitumen Primer is a solvent-based, low-viscosity coating used to prepare and seal surfaces before applying bituminous waterproofing materials like membranes, mastics, or adhesives. It enhances adhesion, fills pores in concrete/metal, and provides a protective layer against moisture and corrosion. Commonly used in roofing, foundations, pipelines, and repair work, it dries quickly and forms a strong bond for long-lasting waterproofing. Ideal for both new construction and maintenance projects.

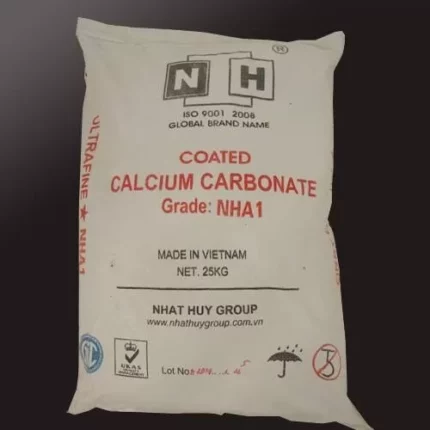

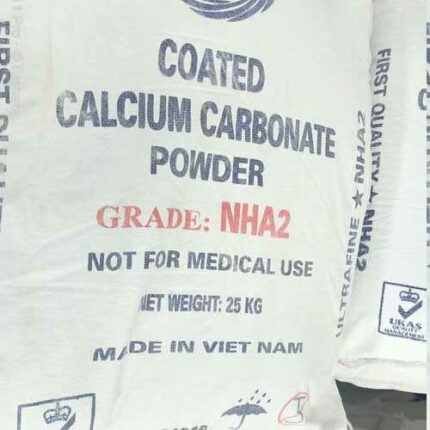

Calcium carbonate (Coated)

Calcium Carbonate (coated) refers to a form of calcium carbonate in which the individual particles of the mineral are coated or encapsulated with a layer of a different material. This layer can be composed of various substances, such as stearic acid, fatty acids, or other polymers. The purpose of the coating is to modify the surface properties of the calcium carbonate particles, such as their hydrophobicity or compatibility with other materials, making them more suitable for specific applications. Coated calcium carbonate is widely used in industries such as plastics, paper, paints, and coatings, where it can improve the properties of the final product, such as brightness, whiteness, and durability.

Calcium Carbonate (uncoated)

Calcium Carbonate (uncoated) refers to a natural mineral substance that is composed of calcium carbonate without any additional coatings or surface treatments. It is a white, powdery material that is commonly used in various industrial applications, including the manufacture of paper, paints, plastics, and rubber products, as well as in construction, agriculture, and the food and pharmaceutical industries. Uncoated calcium carbonate is typically mined from natural deposits of limestone or chalk and is often ground into fine particles to achieve the desired particle size and purity for specific applications

Carnauba Wax

Rated 5.00 out of 5

Carnauba wax is a natural wax derived from the leaves of the carnauba palm tree, scientifically known as Copernicia prunifera. It is considered one of the hardest and highest melting point waxes found in nature. Carnauba wax is widely used in various industries, including automotive, food, pharmaceuticals, and cosmetics, due to its unique properties and versatility.

The best definition of carnauba wax would be that it is a hard, natural wax obtained from the leaves of the carnauba palm tree, primarily used as a protective and polishing agent in various products. It is known for its high melting point, durability, glossy finish, and water-repellent characteristics, making it a popular choice in automotive waxes, polishes, and protective coatings.

Cellulose Ether

Rated 5.00 out of 5

Cellulose ether are a group of water-soluble polymers that are derived from cellulose, which is the most abundant natural polymer on earth. Cellulose ethers are produced by chemically modifying the cellulose molecule through a variety of reactions, such as etherification or esterification, resulting in different functional groups attached to the cellulose backbone. These modifications can alter the physical and chemical properties of cellulose, making it more soluble in water and providing a range of functional properties, such as thickening, binding, stabilizing, and emulsifying, that make cellulose ethers useful in a wide range of industries, including food, pharmaceuticals, cosmetics, and construction.

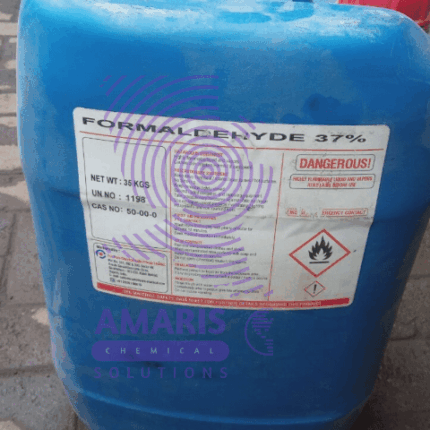

Formalin Formaldehyde

Formalin Formaldehyde is a colorless gas with a pungent odor, which is used as a disinfectant, preservative, and in the production of various materials and chemicals.

Formalin is a solution of formaldehyde gas in water, typically containing 37% formaldehyde by volume. It is commonly used as a tissue preservative in biological specimens for medical and research purposes. Formalin is also used in various industrial applications such as manufacturing plastics, resins, and textiles.

Styrene Acrylic Emulsion Polymer

Styrene Acrylic Emulsion Polymer is a versatile water-based copolymer that combines the beneficial properties of styrene and acrylic components to create a high-performance binding agent. This polymer emulsion is particularly valued for its excellent film-forming characteristics, offering an optimal balance between hardness from styrene and flexibility from acrylic. It serves as a key ingredient in various industrial and commercial applications, including architectural and industrial coatings, where it provides durability, water resistance, and enhanced gloss retention. Additionally, it is widely used in adhesives and sealants for its strong bonding capabilities, in textile and paper coatings for improved wash resistance and printability, and in construction materials to enhance waterproofing and crack resistance in concrete mixtures

LABORATORY EQUIPMENT & APPARATUS

LABORATORY EQUIPMENT & APPARATUS

Fertilizers

Fertilizers Plant Growth Regulators

Plant Growth Regulators Soil Conditioners

Soil Conditioners Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Preservatives (baking)

Preservatives (baking)

Surfactants (cleaning)

Surfactants (cleaning) Builders

Builders Bleaching Agents

Bleaching Agents Enzymes

Enzymes Solvents (cleaning)

Solvents (cleaning) Fragrances

Fragrances

Reviews

There are no reviews yet.