Cellulose Acetate Phthalate (CAP)

Whatsapp Order

Cellulose Acetate Phthalate (CAP) is a cellulose derivative obtained by esterification of cellulose with acetic acid and phthalic anhydride. It appears as a white to off-white, free-flowing powder that is insoluble in water but soluble in alkaline solutions and certain organic solvents. CAP is primarily used as an enteric coating agent in pharmaceutical formulations, providing resistance to acidic gastric fluids and enabling targeted release of drugs in the intestines. Due to its film-forming, pH-sensitive solubility, and protective properties, CAP is also applied in food, cosmetics, and specialty industrial uses.

Description

Table of Contents

Toggle

Cellulose Acetate Phthalate (CAP)

Primary Uses

- Pharmaceutical Industry

- Widely used as an enteric coating polymer for tablets and capsules to prevent dissolution in stomach acid and enable targeted release in the intestines.

- Provides protection for acid-sensitive drugs and reduces gastric irritation.

- Acts as a controlled-release film former in oral dosage forms.

- Food Industry

- Used as a coating agent for confectionery and food products to provide gloss and protective barriers.

- Functions as a controlled-release matrix for flavor and nutrient encapsulation.

- Cosmetics

- Employed in nail polish formulations and other cosmetics for film-forming and gloss-enhancing properties.

- Provides water-resistant coatings.

Secondary Uses

- Packaging Industry

- Utilized in specialty coatings for biodegradable films and packaging materials for controlled permeability.

- Adhesives & Sealants

- Applied as a component in water-resistant adhesives and sealants.

- Printing Industry

- Used in inks and coatings to improve film durability and chemical resistance.

KEY PRODUCT FEATURES

1. Basic Identification Attributes

- Chemical Name (IUPAC): Cellulose, acetate, phthalate

- Common/Trade Name: Cellulose Acetate Phthalate, CAP

- CAS Number: 9004-35-7

- HS Code: 3912.10.00

- Molecular Formula: Variable (cellulose backbone with acetate and phthalate ester substitutions)

- Synonyms:

- CAP

- Cellulose acetate phthalate polymer

- Phthalylated cellulose acetate

2. Physical & Chemical Properties

- Physical State: White to off-white powder

- Color & Odor: White/off-white; virtually odorless

- Melting Point: Decomposes before melting

- Boiling Point: Not applicable

- Density: Approximately 1.3–1.4 g/cm³

- Solubility:

- Insoluble in water and gastric acid (pH <3)

- Soluble in alkaline conditions (pH >6)

- Soluble in acetone, ethanol, and certain organic solvents

- pH Sensitivity: Dissolves at intestinal pH (around 6.8 and above)

- Stability: Stable under dry, cool storage conditions; sensitive to strong acids and bases

3. Safety & Hazard Attributes

- Hazard Class (GHS): Not classified as hazardous under normal use

- NFPA Ratings:

- Health: 0

- Flammability: 1 (combustible dust risk)

- Reactivity: 0

- Exposure Limits: No specific occupational exposure limits; general dust precautions advised

- Toxicity: Non-toxic; widely regarded as safe for pharmaceutical and food uses

- Reactivity: Stable under normal conditions; avoid strong oxidizers and acids

4. Storage & Handling Attributes

- Storage Conditions: Store in a cool, dry place away from moisture and direct sunlight

- Container Type: Sealed, moisture-proof containers or bags (plastic or foil-lined)

- Shelf Life: Typically 2–3 years if stored properly

- Special Handling: Avoid dust generation and inhalation; use PPE when handling powders

5. Regulatory & Compliance Attributes

- FDA Status: Approved as a pharmaceutical excipient and food additive in regulated uses

- REACH Status: Registered

- Transportation: Not regulated as hazardous material

- Waste Disposal: Dispose according to local regulations; biodegradable under industrial composting

6. Environmental & Health Impact

- Ecotoxicity: Low environmental impact; biodegradable under aerobic conditions

- Persistence: Moderate biodegradability; slow in some conditions

- Bioaccumulation: Not expected to bioaccumulate

- Carcinogenicity/Mutagenicity: Not classified as carcinogenic or mutagenic

- Biodegradability: Biodegradable, but may require controlled conditions

SAFETY HANDLING PRECAUTIONS

Safety Handling Precautions

Personal Protective Equipment (PPE):

- Dust mask or respirator for powder handling

- Safety goggles

- Gloves recommended

Handling Measures:

- Avoid dust formation and accumulation

- Use in well-ventilated areas

- Prevent contact with strong acids or oxidizers

Storage Measures:

- Keep containers tightly sealed and dry

- Store away from heat and ignition sources

Hygiene Practices:

- Wash hands after handling

- Avoid eating, drinking, or smoking while handling product

First Aid Measures

- Inhalation: Remove to fresh air; seek medical attention if irritation occurs

- Skin Contact: Wash with soap and water; seek medical advice if irritation persists

- Eye Contact: Flush with water for 15 minutes; seek medical attention if irritation continues

- Ingestion: Non-toxic; rinse mouth and seek medical advice if large quantities ingested

Firefighting Measures

- Fire Hazards: Combustible powder; may produce dust explosion hazard

- Extinguishing Media: Use water spray, foam, dry chemical, or CO₂

- Special Precautions: Avoid dust accumulation; firefighters should wear protective equipment and respiratory protection

- Decomposition Products: Carbon oxides, phthalic anhydride, and acetic acid vapors under thermal decomposition

Related products

Ammonia Acetate

Ammonia Acetate is a white crystalline solid or granular powder with a mild ammoniacal odor. It is a salt formed from ammonia and acetic acid, widely used in laboratories, industrial processes, and some niche food and pharmaceutical applications. Ammonium Acetate is highly soluble in water and often utilized as a buffer solution in biochemical and analytical chemistry due to its ability to maintain pH. It also serves as a precursor in the synthesis of various chemicals and acts as a neutralizing agent in several industrial applications.

Avobenzone

Avobenzone (chemical name: Butyl Methoxydibenzoylmethane) is an oil-soluble organic compound widely used as a UVA filter in sunscreen formulations. It is valued for its ability to absorb a broad spectrum of ultraviolet A (UVA) rays (320–400 nm), protecting the skin from premature aging and damage caused by sun exposure. Avobenzone is often combined with other UV filters to provide broad-spectrum sun protection. It is a pale yellow liquid or crystalline powder, soluble in oils and alcohols but unstable in sunlight unless stabilized with other agents.

Hydroxypropyl Methylcellulose

Hydroxypropyl Methylcellulose HPMC, also known as hypromellose, is a semi-synthetic, non-ionic cellulose ether derived by chemically modifying cellulose through methylation and hydroxypropylation. It is a white to off-white, odorless, tasteless powder that dissolves in cold water to form clear, viscous solutions. HPMC is renowned for its thickening, film-forming, emulsifying, and controlled-release properties. It is widely used in pharmaceuticals, food, cosmetics, construction, and industrial applications due to its safety profile, versatility, and compatibility with various ingredients.

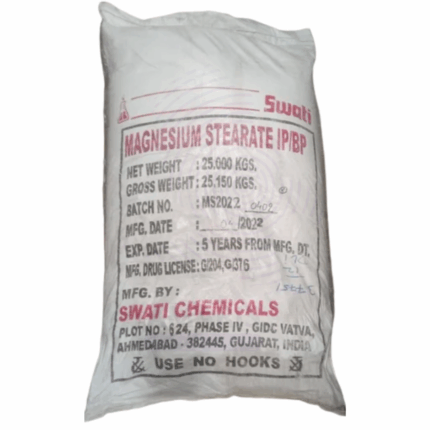

Magnesium Stearate BP

Magnesium Stearate BP is a fine, white, hydrophobic powder composed of the magnesium salt of stearic acid. It is widely used in the pharmaceutical industry as a lubricant and anti-adherent in tablet and capsule manufacturing. Due to its excellent flow-enhancing properties, Magnesium Stearate BP improves powder flowability and prevents ingredients from sticking to equipment during processing. It is also used in cosmetics, food, and various industrial applications for its emulsifying and stabilizing properties.

Methyl Cellulose 400mpc

Methyl Cellulose 400mpc is a chemically modified cellulose derivative in powder form. It is a non-ionic, water-soluble polymer widely used as a thickener, binder, emulsifier, and film former. It exhibits excellent water retention, viscosity control, and thermal gelation properties, making it ideal for applications in construction, pharmaceuticals, food, and cosmetics.

Polyethyl Glycol( PEG 6000)

Polyethyl Glycol( PEG 6000) is a high-molecular-weight polymer derived from ethylene oxide. It appears as a white, waxy solid or flake and is non-toxic, water-soluble, and chemically stable. PEG 6000 is widely used in pharmaceuticals, cosmetics, food processing, industrial formulations, and biotechnology, valued for its lubricating, solubilizing, binding, and moisturizing properties. It is odorless and tasteless, making it suitable for sensitive formulations.

Povidone PVP25 USP

Povidone PVP25 USP is a synthetic polymer of vinylpyrrolidone with an average molecular weight of approximately 25,000. It is a water-soluble, non-toxic, and biodegradable polymer widely used as a binder, film former, stabilizer, and solubilizing agent in pharmaceutical, cosmetic, and industrial applications. Its excellent adhesive properties and compatibility with a wide range of substances make it essential in tablet formulations, topical products, and adhesives.

Red Cherry Powder Flavor

Red Cherry Powder Flavor is a high-quality, concentrated flavoring agent designed to impart a natural and vibrant cherry taste to a variety of food and beverage applications. This fine powder is made from carefully selected ingredients to ensure consistent flavor intensity, solubility, and stability. Ideal for use in dry mixes, confectionery, beverages, and baked goods, Red Cherry Powder Flavor provides a convenient and versatile way to enhance taste profiles without altering texture.

Preservatives(food)

Preservatives(food) Flavor Enhancers

Flavor Enhancers Acidulants

Acidulants Sweeteners

Sweeteners Antioxidants

Antioxidants Colorants(food)

Colorants(food) Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food) Nutrient Supplements

Nutrient Supplements Emulsifiers

Emulsifiers

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Solvents(lab)

Solvents(lab) Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents microbiology-and-cell-culture-reagents

microbiology-and-cell-culture-reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders