Construction Chemicals are specialized compounds used to enhance the performance, durability, and efficiency of building materials and structures. These additives play a critical role in modern construction by improving the properties of concrete, mortar, adhesives, and coatings. Key types include concrete admixtures (water reducers, accelerators, retarders), waterproofing agents, repair mortars, protective coatings, and sealants. They help achieve faster curing times, increased strength, crack resistance, weatherproofing, and corrosion protection. From high-rise buildings to infrastructure projects, construction chemicals ensure longevity, safety, and cost-effectiveness while meeting stringent quality standards.

Bentonite powder is a naturally occurring absorbent clay primarily composed of montmorillonite, a type of smectite clay mineral. It exhibits excellent swelling and water absorption properties, making it highly versatile in industrial and commercial applications. Bentonite forms a gel-like substance when mixed with water, which imparts viscosity and plasticity. It is used extensively for its binding, sealing, and adsorptive characteristics. Its fine powder form allows for easy incorporation in various processes including drilling, foundry, cosmetics, pharmaceuticals, and agriculture.

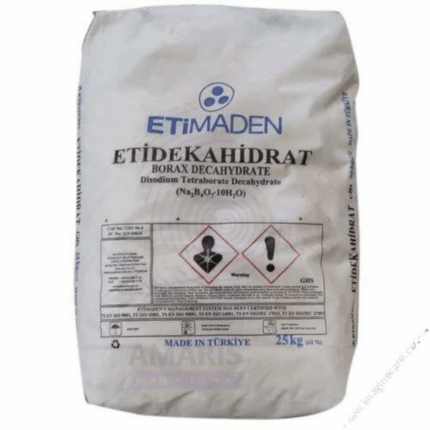

Borax Decahydrate, also known as sodium tetraborate decahydrate, is a naturally occurring mineral and an important inorganic compound. It appears as colorless or white crystalline granules or powder with a salty, alkaline taste. This compound is widely used in detergents, cosmetics, glass manufacturing, agriculture, and various industrial applications due to its excellent buffering, emulsifying, and antiseptic properties. The “decahydrate” indicates that each molecule of borax contains ten water molecules bound in its crystal structure, contributing to its crystalline appearance and physical properties.

Calcium Carbonate Heavy is a high-density, finely ground, natural mineral primarily composed of calcium carbonate (CaCO₃). Known for its higher bulk density compared to regular grades, this filler is widely used in applications requiring enhanced weight, opacity, and strength. It is commonly employed as a functional filler and extender in industries such as plastics, paints, coatings, adhesives, rubber, paper, and construction materials. Its inert nature, whiteness, and particle size distribution make it suitable for improving mechanical properties and surface finish, while also offering cost efficiency by replacing more expensive raw materials.

Calcium Carbonate Uncoated is a naturally occurring mineral compound composed primarily of calcium, carbon, and oxygen with the chemical formula CaCO₃. It appears as a fine white powder or granules, widely used as a filler, pigment, and functional additive across various industries. The uncoated form means the calcium carbonate particles are not surface-treated, retaining their natural properties. It is valued for its high brightness, whiteness, and excellent compressibility. Uncoated calcium carbonate is used to enhance opacity, improve processing, and reduce costs in plastics, paints, coatings, adhesives, rubber, paper, and construction materials.

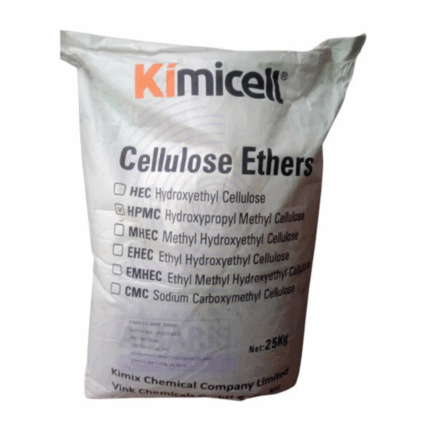

Cellulose ether refers to a group of chemically modified cellulose derivatives where hydroxyl groups on the cellulose backbone are substituted with ether groups such as methyl, hydroxyethyl, or carboxymethyl groups. These modifications improve solubility, viscosity, and film-forming properties while maintaining biodegradability and non-toxicity. Cellulose ethers are white to off-white powders or granules that dissolve in water to form viscous, stable solutions. They are widely used as thickeners, binders, stabilizers, and film formers in industries such as construction, pharmaceuticals, cosmetics, food, and paper.

CMC Sodium, or Carboxymethyl Cellulose Sodium, is a water-soluble anionic cellulose ether derived from natural cellulose. It appears as a white to off-white, odorless, tasteless powder or granule. Known for its excellent thickening, stabilizing, emulsifying, and water-retention properties, CMC is widely used in food, pharmaceutical, personal care, industrial, and detergent applications. It functions by modifying the rheological properties of solutions and suspensions, offering control over viscosity and flow. Its biocompatibility, non-toxicity, and biodegradability make it suitable for both human use and environmentally friendly formulations.

CMC Sodium Blanose is a high-purity, pharmaceutical- and food-grade Sodium Carboxymethyl Cellulose (CMC), manufactured under the Blanose® brand by Ashland or equivalent producers. It is a water-soluble, anionic cellulose ether derived from natural cellulose, designed for superior consistency, clarity, and performance. CMC Blanose serves as a thickening agent, stabilizer, binder, film former, and emulsifier in a wide variety of applications. Known for its excellent rheological control and water retention, it is widely used across the food, pharmaceutical, personal care, and industrial sectors, offering reliable performance with batch-to-batch consistency.

Defoamer is a high-performance, silicone-based antifoaming agent designed to eliminate and prevent foam formation in aqueous and non-aqueous systems. It is typically a milky-white or translucent emulsion composed of modified polydimethylsiloxane, hydrophobic silica, and proprietary surfactants or emulsifiers. Defoamer is known for its immediate foam knockdown, long-lasting suppression, and compatibility across diverse formulations. It is widely used in industrial processes, coatings, adhesives, water treatment, textiles, and more. It is effective at low concentrations, thermally stable, and resistant to shear and pH fluctuations.

HPMC Vivapharm is a high-quality, pharmaceutical-grade hydroxypropyl methylcellulose polymer widely used as an excipient and functional ingredient. It appears as a fine, white to off-white, odorless powder with excellent solubility in cold water and forms clear, viscous solutions. This cellulose ether derivative offers excellent film-forming, thickening, emulsifying, and controlled-release properties. Vivapharm E50 is prized in pharmaceutical, food, and cosmetic industries for its versatility, stability, and safety profile.

Hydroxyethyl Cellulose , marketed under brand names such as Natrosol, is a non-ionic, water-soluble polymer derived from cellulose by reacting alkali cellulose with ethylene oxide. It appears as a white to off-white, free-flowing powder with excellent thickening, binding, and film-forming properties. HEC is widely used as a rheology modifier and stabilizer due to its high water retention, solubility, and compatibility with a broad range of ingredients. It is valued in many industries including cosmetics, pharmaceuticals, paints, adhesives, and personal care products.

Hydroxypropyl Methylcellulose HPMC, also known as hypromellose, is a semi-synthetic, non-ionic cellulose ether derived by chemically modifying cellulose through methylation and hydroxypropylation. It is a white to off-white, odorless, tasteless powder that dissolves in cold water to form clear, viscous solutions. HPMC is renowned for its thickening, film-forming, emulsifying, and controlled-release properties. It is widely used in pharmaceuticals, food, cosmetics, construction, and industrial applications due to its safety profile, versatility, and compatibility with various ingredients.

Lactic Acid is a colorless to pale yellow, viscous liquid with a mild acidic odor. It is an organic acid naturally produced by fermentation and widely used in industrial, pharmaceutical, cosmetic, and food applications. The 80% concentration provides a balance of potency and ease of handling, making it suitable for pH adjustment, preservation, and chemical synthesis. Lactic acid is biodegradable, non-toxic, and valued for its multifunctionality including antimicrobial properties and chelation abilities.

Methyl Cellulose 400 MPC is a chemically modified cellulose derivative in powder form. It is a non-ionic, water-soluble polymer widely used as a thickener, binder, emulsifier, and film former. It exhibits excellent water retention, viscosity control, and thermal gelation properties, making it ideal for applications in construction, pharmaceuticals, food, and cosmetics.

Styrene Acrylic is a copolymer emulsion combining styrene and acrylic monomers, widely used as a versatile binder in coatings, adhesives, and construction materials. It offers excellent film-forming properties, adhesion, water resistance, and durability. This product enhances the performance and longevity of paints, sealants, textiles, and paper coatings, with flexibility for both indoor and outdoor applications. Styrene Acrylic emulsions are designed to meet stringent industrial and environmental standards.

Styrene Acrylic Emulsion Polymer is a water-based copolymer emulsion combining styrene and acrylic monomers, designed as a versatile binder with excellent film formation, adhesion, and durability. Widely used across paints, coatings, adhesives, textiles, and construction materials, this polymer offers superior weather resistance, water repellency, and flexibility. Its emulsified form enables easy incorporation into aqueous formulations, delivering enhanced performance and environmental benefits by reducing VOC emissions.

TDI is a highly reactive chemical compound primarily used as a key raw material in the production of polyurethane foams. It is a colorless to pale yellow liquid with a pungent odor and is valued for its ability to react with polyols to form flexible and rigid polyurethane products. TDI’s versatility makes it indispensable in industries like furniture, automotive, insulation, and coatings.

Whiting is a finely ground, white, chalky substance primarily composed of calcium carbonate (CaCO₃). It is widely used as a pigment, filler, and extender in various industrial and commercial applications. Whiting provides opacity, brightness, and smoothness to products, enhancing their appearance and physical properties. Its natural abundance and versatility make it an economical additive in multiple manufacturing processes.

Yellow Oxide 920 is a high-quality, synthetic iron oxide pigment characterized by its bright yellow color, excellent tinting strength, and outstanding durability. It is widely used as a colorant in coatings, plastics, construction materials, and other industrial applications. This pigment provides excellent weather resistance, chemical stability, and heat stability, ensuring vibrant and long-lasting color performance in various end products.

Acidulants

Acidulants Antioxidants

Antioxidants Nutraceutical Ingredients (food)

Nutraceutical Ingredients (food)

Collectors

Collectors Dust Suppressants

Dust Suppressants Explosives and Blasting Agents

Explosives and Blasting Agents Flocculants and Coagulants

Flocculants and Coagulants Frothers

Frothers Leaching Agents

Leaching Agents pH Modifiers

pH Modifiers Precious Metal Extraction Agents

Precious Metal Extraction Agents

Antioxidants(plastic)

Antioxidants(plastic) Colorants (Pigments, Dyes)

Colorants (Pigments, Dyes) Fillers and Reinforcements

Fillers and Reinforcements Flame Retardants

Flame Retardants Monomers

Monomers Plasticizers

Plasticizers Polymerization Initiators

Polymerization Initiators Stabilizers (UV, Heat)

Stabilizers (UV, Heat)

Antifoaming Agents

Antifoaming Agents Chelating Agents

Chelating Agents Coagulants and Flocculants

Coagulants and Flocculants Corrosion Inhibitors

Corrosion Inhibitors Disinfectants and Biocides

Disinfectants and Biocides Oxidizing Agents

Oxidizing Agents pH Adjusters

pH Adjusters Scale Inhibitors( water)

Scale Inhibitors( water)

Antioxidants(cosmetic)

Antioxidants(cosmetic) Emollients

Emollients Fragrances and Essential Oils

Fragrances and Essential Oils Humectants

Humectants Preservatives

Preservatives Surfactants(cosmetic)

Surfactants(cosmetic) Thickeners

Thickeners UV Filters

UV Filters

Fertilizers

Fertilizers Soil Conditioners

Soil Conditioners Plant Growth Regulators

Plant Growth Regulators Animal Feed Additives

Animal Feed Additives Biostimulants

Biostimulants Pesticides (Herbicides, Insecticides, Fungicides)

Pesticides (Herbicides, Insecticides, Fungicides)

Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) Excipients

Excipients Solvents(pharmaceutical)

Solvents(pharmaceutical) Antibiotics

Antibiotics Antiseptics and Disinfectants

Antiseptics and Disinfectants Vaccine Adjuvants

Vaccine Adjuvants Nutraceutical Ingredients (pharmaceutical)

Nutraceutical Ingredients (pharmaceutical) Analgesics & Antipyretics

Analgesics & Antipyretics

Analytical Reagents

Analytical Reagents Chromatography Chemicals

Chromatography Chemicals Spectroscopy Reagents

Spectroscopy Reagents Molecular Biology Reagents

Molecular Biology Reagents Biochemical Reagents

Biochemical Reagents Inorganic and Organic Standards

Inorganic and Organic Standards Laboratory Safety Chemicals

Laboratory Safety Chemicals Specialty Laboratory Chemicals(Special Laboratory Equipment)

Specialty Laboratory Chemicals(Special Laboratory Equipment)

Demulsifiers

Demulsifiers Hydraulic Fracturing Fluids

Hydraulic Fracturing Fluids Scale Inhibitors(oil)

Scale Inhibitors(oil) Surfactants(oil)

Surfactants(oil) Drilling Fluids

Drilling Fluids

Dyes and Pigments

Dyes and Pigments Bleaching Agents

Bleaching Agents Softening Agents

Softening Agents Finishing Agents

Finishing Agents Antistatic Agents

Antistatic Agents

Admixtures

Admixtures Waterproofing Agents

Waterproofing Agents Sealants and Adhesives

Sealants and Adhesives Curing Compounds

Curing Compounds Concrete Repair Chemicals

Concrete Repair Chemicals Anti-Corrosion Coatings

Anti-Corrosion Coatings

Surfactants(cleaning)

Surfactants(cleaning) Builders

Builders Enzymes

Enzymes Solvents (Cleaning)

Solvents (Cleaning) Fragrances

Fragrances

Electronic Chemicals

Electronic Chemicals Catalysts

Catalysts Lubricants

Lubricants Photographic Chemicals

Photographic Chemicals Refrigerants

Refrigerants Automotive chemicals

Automotive chemicals Pyrotechnic Chemicals

Pyrotechnic Chemicals

Biodegradable Surfactants

Biodegradable Surfactants Bio-based Solvents

Bio-based Solvents Renewable Polymers

Renewable Polymers Carbon Capture Chemicals

Carbon Capture Chemicals Wastewater Treatment Chemicals

Wastewater Treatment Chemicals

Pigments

Pigments Solvents(paint)

Solvents(paint) Specialty Coatings

Specialty Coatings Binders/Resins

Binders/Resins Additives

Additives Driers

Driers Anti-Corrosion Agents

Anti-Corrosion Agents Functional Coatings

Functional Coatings Application-Specific Coatings

Application-Specific Coatings

Fresh Herbs

Fresh Herbs Ground Spices

Ground Spices Whole Spices

Whole Spices Spice Blends

Spice Blends Dried Herbs

Dried Herbs

Leavening Agents

Leavening Agents Dough Conditioners

Dough Conditioners Flour Treatments

Flour Treatments Fat Replacers

Fat Replacers Decoratives

Decoratives Preservatives(baking)

Preservatives(baking)

Plasticizers & Softeners

Plasticizers & Softeners Reinforcing Agents

Reinforcing Agents Adhesion Promoters

Adhesion Promoters Vulcanizing Agents

Vulcanizing Agents Antidegradants

Antidegradants Blowing Agents

Blowing Agents Fillers & Extenders

Fillers & Extenders Accelerators & Retarders

Accelerators & Retarders